Gas bag cleaning device and method

A technology for cleaning devices and inflating devices, which is applied in the directions of cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of secondary pollution, environmental pollution, economic waste, etc., and achieve cost savings and avoid secondary pollution. , the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

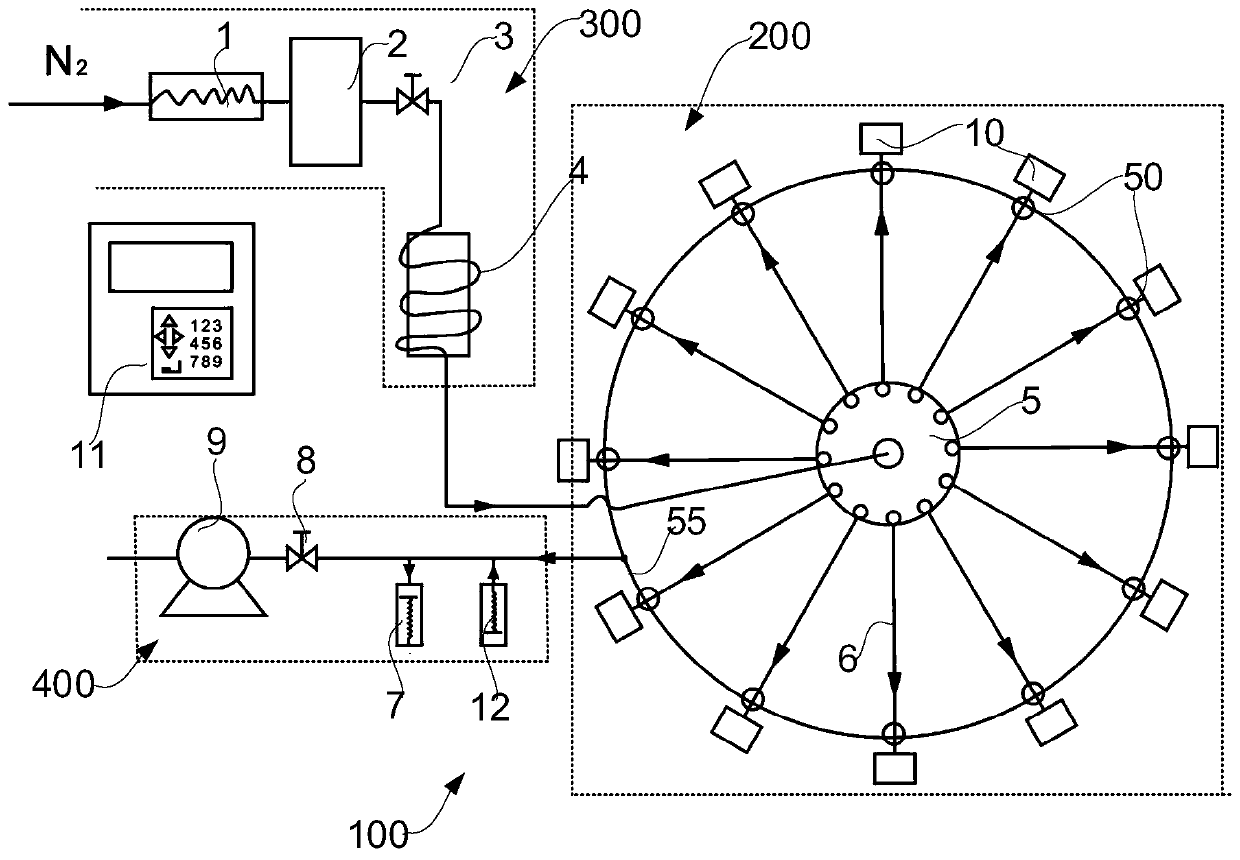

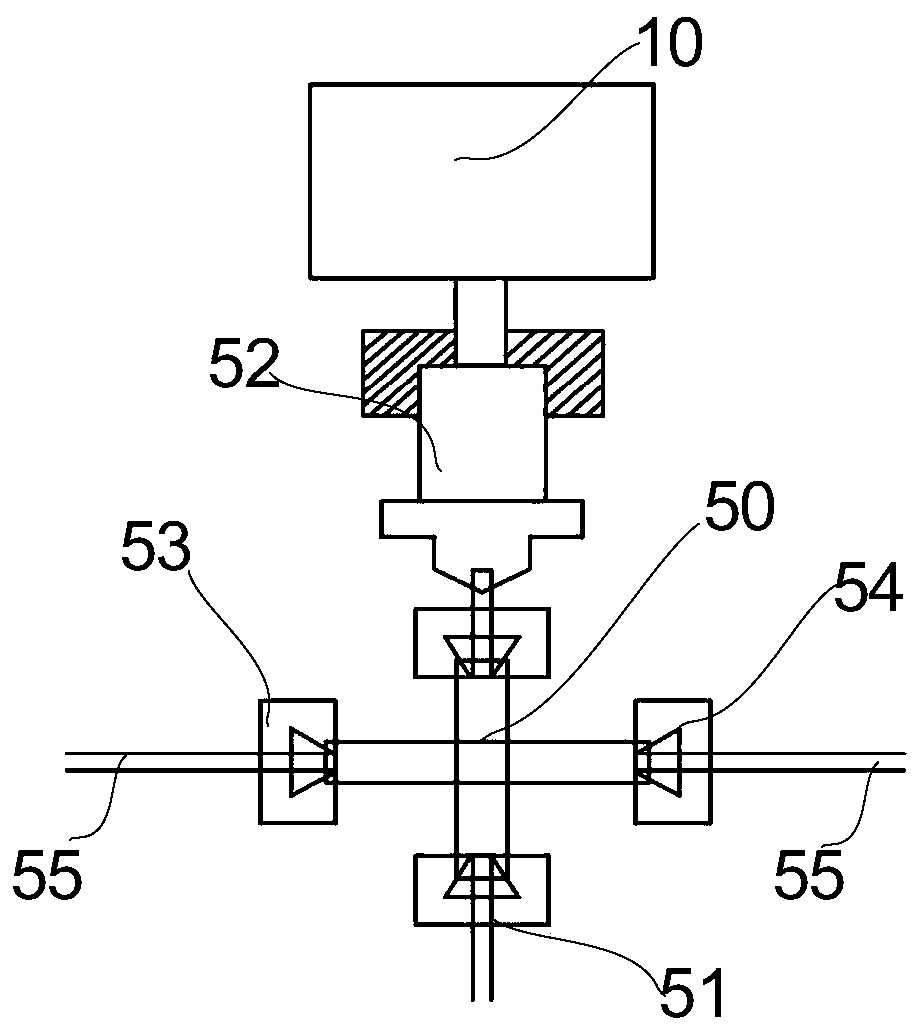

Method used

Image

Examples

experiment Embodiment 1

[0054] The 16 1L air bags to be tested and cleaned contain acetone gas with nitrogen as the medium, and the concentrations are 1ppm, 5ppm, 10ppm, and 20ppm. Acetone, as a common chemical reagent, is often used in the production process of chemical industry and electronics. , whose characteristics are water-soluble compounds.

[0055] First set the conditions: cleaning and inflating a cycle time: 1 minute

[0056] Heater temperature: 80 degrees

[0057] Number of cleaning cycles: 3

[0058] The following operation stages are only for the convenience of understanding the embodiment of the present invention, and the sequence of operations does not constitute the necessary steps of the cleaning method of the air bag.

[0059] 1. Pumping stage

[0060] (1) The air outlet solenoid valve 8 is opened by the controller 11, the air pump 9 works, and the gas in the heater 4, the air bag, and the 12-position gas distributor 5 is sucked away.

[0061] (2) The suction force of the air p...

experiment Embodiment 2

[0078] The 16 1L air bags to be tested and cleaned contain benzene gas with nitrogen as the medium, and the concentrations are 1ppm, 5ppm, 10ppm, and 20ppm. As a common chemical reagent, benzene is often used in the production of chemical industry, electronics, and pesticides. in process. It is very toxic and is a major carcinogen.

[0079] Set conditions:

[0080] Cleaning and inflation cycle time: 1 minute

[0081] Heater temperature: 80 degrees

[0082] Number of cleaning cycles: 3

[0083] Basically, the same operation steps as in Experimental Example 1 are adopted, and details are not repeated here.

[0084] After the cleaning is completed, pour 500ml of clean nitrogen into the air bags with different concentrations of 1ppm, 5ppm, 10ppm, and 20ppm, and analyze the concentrations and residues by using a mass spectrometer according to the standard method of environmental standard HJ734, as shown in the following table:

[0085] Table 2, cleaning three times (injection ...

experiment Embodiment 3

[0088] The 16 1L air bags to be tested and cleaned contain hexachloro-1,3-butadiene gas with nitrogen as the medium, the concentration is 1ppm, 2ppm, 4ppm, 5ppm, hexachloro-1,3-butadiene gas Alkene has a high boiling point and is a poisonous substance.

[0089] Set conditions:

[0090] Cleaning and inflation cycle time: 1 minute

[0091] Heater temperature: 80 degrees

[0092] Number of cleaning cycles: 3

[0093] Basically, the same operation steps as in Experimental Example 1 are adopted, and details are not repeated here.

[0094] After the cleaning is completed, pour 500ml of clean nitrogen into the air bags with different concentrations of 1ppm, 5ppm, 10ppm, and 20ppm, and use a mass spectrometer to analyze the concentrations and residues according to the standard method of environmental standard HJ734, as shown in the following table:

[0095] Table 3, cleaning three times (injection volume of sample test is 300ml)

[0096]

[0097]

[0098] 3 embodiments are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com