Negative electrode composite slurry and preparation method thereof, lithium battery negative electrode sheet

A technology of composite slurry and negative electrode, applied in the field of negative electrode composite slurry and its preparation, can solve the problems of blocking lithium ion diffusion channels, affecting the rate performance of lithium batteries, increasing battery impedance, etc., and achieving good lithium ion transmission effect and isolation. Good thermal effect, reducing clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A negative electrode composite slurry, comprising the following components in weight percentage: 1.20% ultrafine glass fiber; 17.22% aluminum oxide powder; 1.20% low-viscosity carboxymethyl cellulose; 0.40% high-viscosity carboxymethyl cellulose; Benzene emulsion 0.10%; and water 79.88%. Wherein, the solid content of the styrene-butadiene emulsion is 50%.

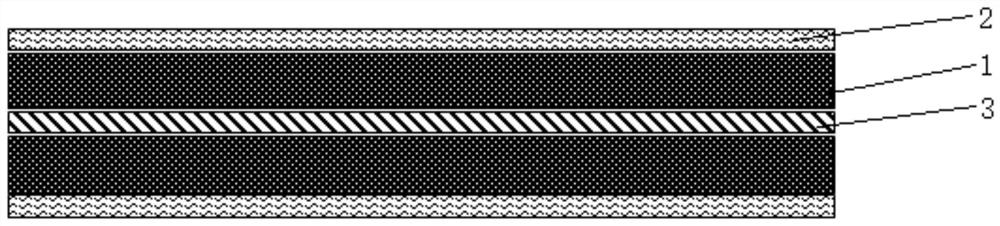

[0034] see figure 1 , a lithium battery negative electrode sheet, comprising a negative electrode active material layer 1, a negative electrode composite coating 2 and a negative electrode current collector 3, the upper and lower surfaces of the negative electrode current collector 3 are coated with a negative electrode active material layer 1, and on the negative electrode active material layer 1 Coated with negative electrode composite coating 2. Wherein, the negative electrode current collector 3 may be copper foil.

[0035] A method for preparing a lithium battery negative pole piece, comprising the following ...

Embodiment 2

[0042] A negative electrode composite slurry, comprising the following components in weight percentage: 1.20% ultrafine glass fiber; 17.22% aluminum oxide powder; 1.10% low-viscosity carboxymethyl cellulose; 0.50% high-viscosity carboxymethyl cellulose; Benzene emulsion 0.10%; and water 79.88%. Wherein, the solid content of the styrene-butadiene emulsion is 50%.

[0043] A method for preparing a lithium battery negative pole piece, comprising the following steps:

[0044] 1) According to the formulation amount, mix low-viscosity carboxymethyl cellulose, high-viscosity carboxymethyl cellulose and water, put them into a planetary mixer for stirring and mixing, and obtain a dispersed aqueous solution.

[0045] 2) Mix ultrafine glass fiber and alumina powder evenly to obtain a mixture, add a predetermined amount of dispersion solution to the mixture, the predetermined amount of dispersion solution accounts for 8% of the total mass of the dispersion solution, stir for 40 minutes, ...

Embodiment 3

[0050] A negative electrode composite slurry, comprising the following components in weight percentage: 1.00% ultrafine glass fiber; 17.42% boehmite powder; 1.20% low-viscosity carboxymethyl cellulose; 0.40% high-viscosity carboxymethyl cellulose; Benzene emulsion 0.10%; and water 79.88%. Wherein, the solid content of the styrene-butadiene emulsion is 50%.

[0051] A method for preparing a lithium battery negative pole piece, comprising the following steps:

[0052] 1) According to the formulation amount, mix low-viscosity carboxymethyl cellulose, high-viscosity carboxymethyl cellulose and water, put them into a planetary mixer for stirring and mixing, and obtain a dispersed aqueous solution.

[0053] 2) Mix ultrafine glass fiber and boehmite powder evenly to obtain a mixture, add a predetermined amount of dispersion solution to the mixture, the predetermined amount of dispersion solution accounts for 10% of the total mass of the dispersion solution, stir for 30 minutes, stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com