Graphene oxide modified coal pitch binder and preparation method thereof

A graphene modification and coal pitch technology, applied in the field of materials, can solve problems such as limited modification effect, and achieve the effects of improving oxidation resistance, protecting the ecological environment, and reducing carbon consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Media dispersion: Add the graphene oxide powder to high-purity absolute ethanol at a mass ratio of 10%, and apply ultrasonic waves (60KHz) to strengthen the dispersion for 60 minutes to obtain a uniformly dispersed mixed sol of graphene oxide.

[0023] Ingredients and mixing: the graphene oxide sol and coal tar powder obtained above are fully stirred and mixed according to the actual control in which the amount of graphene oxide is 1.0% (mass ratio) to obtain an intermediate mixture of graphene oxide-coal tar pitch-medium liquid.

[0024] Separation and purification: the obtained intermediate mixture is heated and stirred at 90-150°C to evaporate anhydrous ethanol, and then dried, and cooled to obtain a graphene oxide modified coal pitch binder.

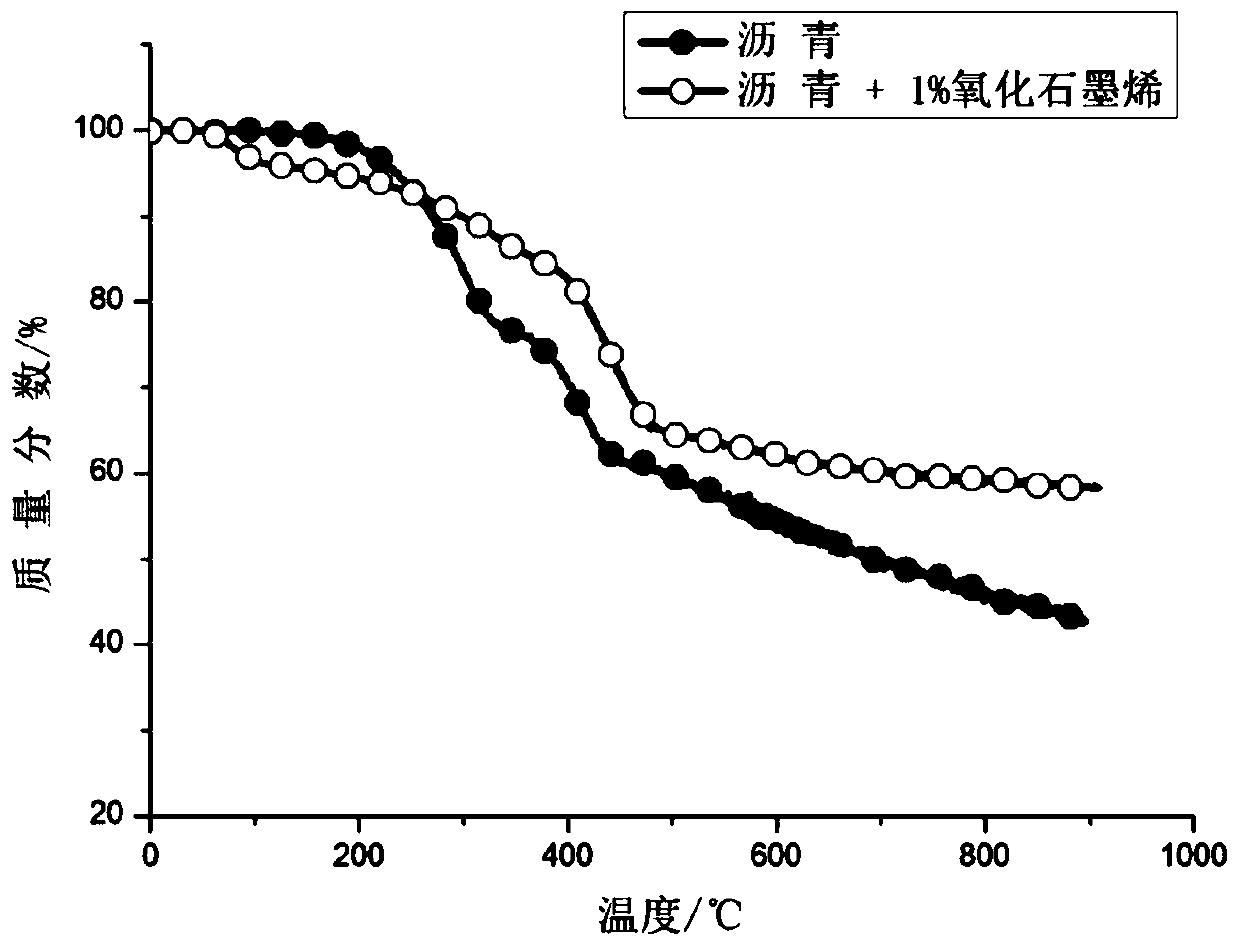

[0025] The obtained graphene oxide modified coal tar pitch binder was tested at high temperature. The results showed that compared with the coal tar pitch (unmodified) under the same conditions, the obtained graphene oxide modified co...

Embodiment 2

[0027] The raw materials used are the same as in Example 1.

[0028] Media dispersion: Add the graphene oxide powder to high-purity absolute ethanol at a mass ratio of 10%, and apply ultrasonic waves (60KHz) to strengthen the dispersion for 60 minutes to obtain a uniformly dispersed mixed sol of graphene oxide.

[0029] Ingredients and mixing: the graphene oxide sol and coal tar powder obtained above are fully stirred and mixed according to the actual control in which the amount of graphene oxide is 1.0% (mass ratio) to obtain an intermediate mixture of graphene oxide-coal tar pitch-medium liquid.

[0030] Separation and purification: the obtained intermediate mixture is heated and stirred at 90-150°C to evaporate anhydrous ethanol, and then dried, and cooled to obtain a graphene oxide modified coal pitch binder.

[0031] The graphene oxide modified coal tar pitch binder was carbonized at 900°C, and the microstructure of the obtained solid sample was analyzed. The results showed that t...

Embodiment 3

[0033] The raw materials used are the same as in Examples 1 and 2.

[0034] Media dispersion: Add the graphene oxide powder to high-purity absolute ethanol at a mass ratio of 10%, and apply ultrasonic waves (60KHz) to strengthen the dispersion for 60 minutes to obtain a uniformly dispersed mixed sol of graphene oxide.

[0035] Ingredients and mixing: the graphene oxide sol and coal tar powder obtained above are fully stirred and mixed according to the actual control in which the amount of graphene oxide is 1.0% (mass ratio) to obtain an intermediate mixture of graphene oxide-coal tar pitch-medium liquid.

[0036] Separation and purification: the obtained intermediate mixture is heated, stirred and evaporated at 90-150°C to remove the absolute ethanol in it, and then dried, and cooled to obtain a graphene oxide modified coal pitch binder.

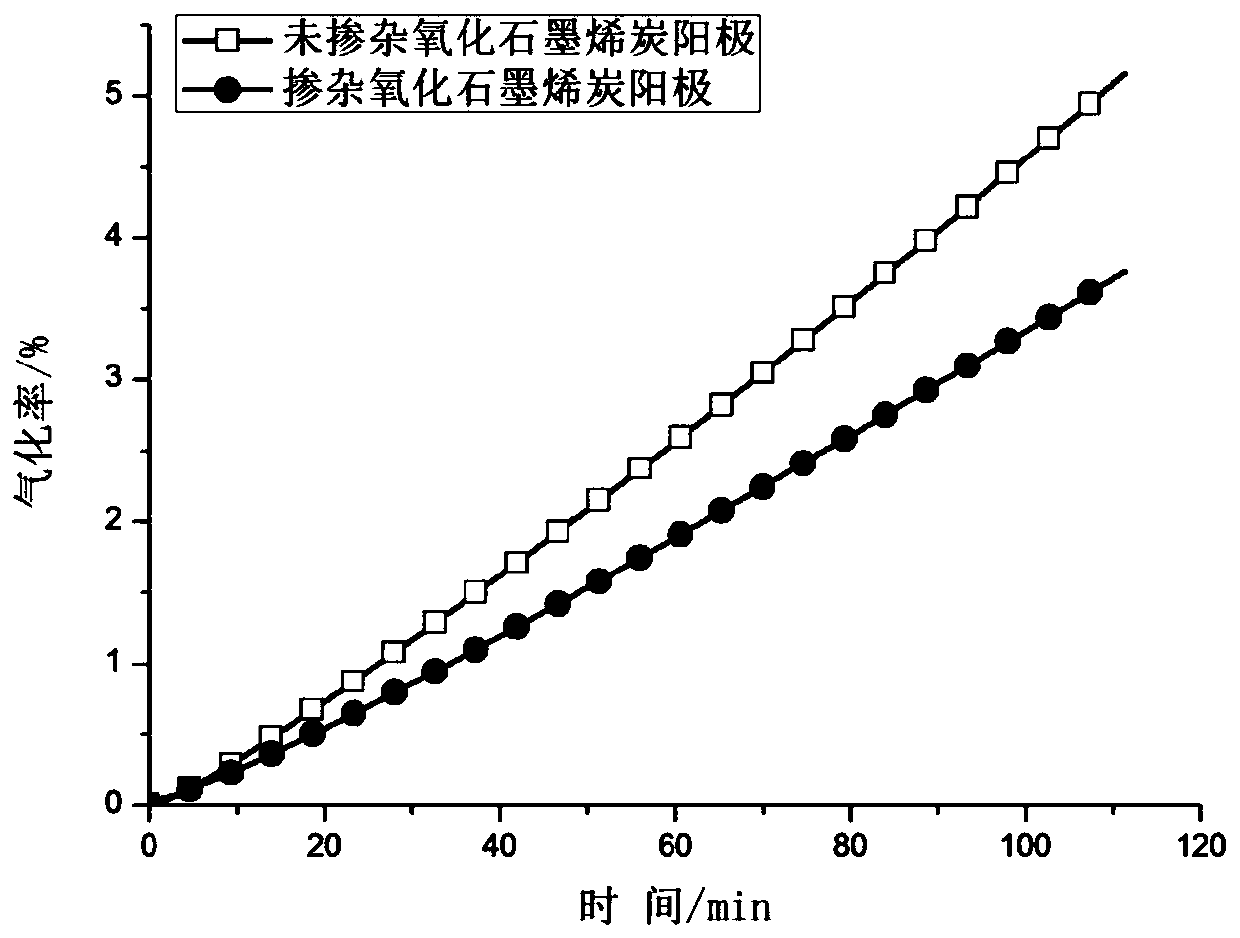

[0037] Kneading and sintering: The obtained graphene oxide modified coal pitch binder and solid carbon particles are mixed and kneaded at 100-150℃ a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com