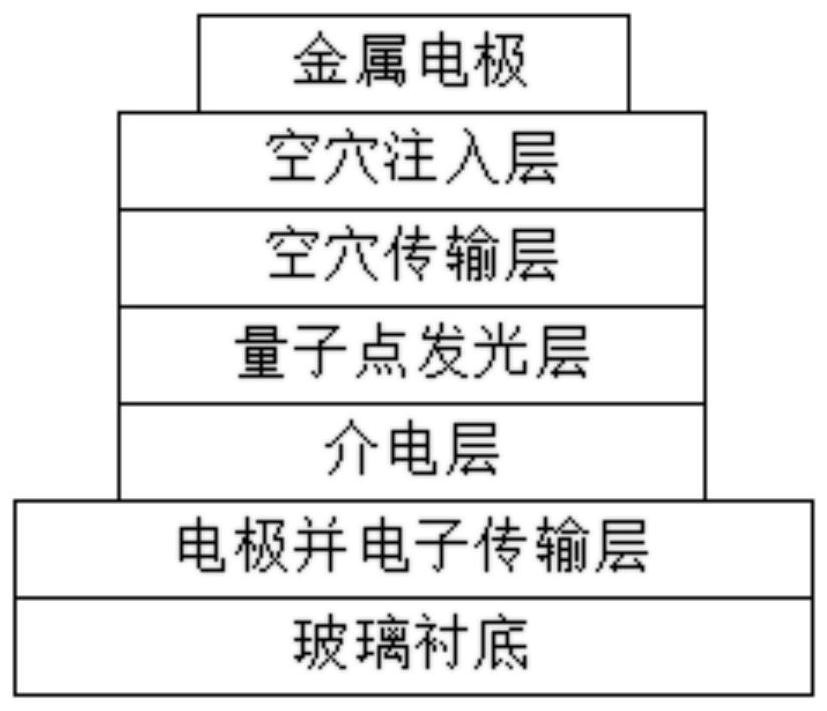

A quantum dot light-emitting device with a double-functional electron transport layer inverted structure and its preparation method

A technology of quantum dot luminescence and electron transport layer, which is applied in the field of flat panel display, and can solve problems affecting device brightness and efficiency, and limiting the use of organic hole transport layer materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A method for preparing a double-functional electron transport layer inverted structure quantum dot light-emitting device, comprising the following steps:

[0058] 1) Preparation of the glass substrate: Cut the glass into a size of 20×16mm to obtain a glass substrate, place it in a solution mixed with detergent for ultrasonic cleaning for 10 minutes, then place it in acetone for 30 minutes, and then place it in ethanol for cleaning 20min, and finally ultrasonic cleaning in deionized water for 10min, drying after cleaning for later use.

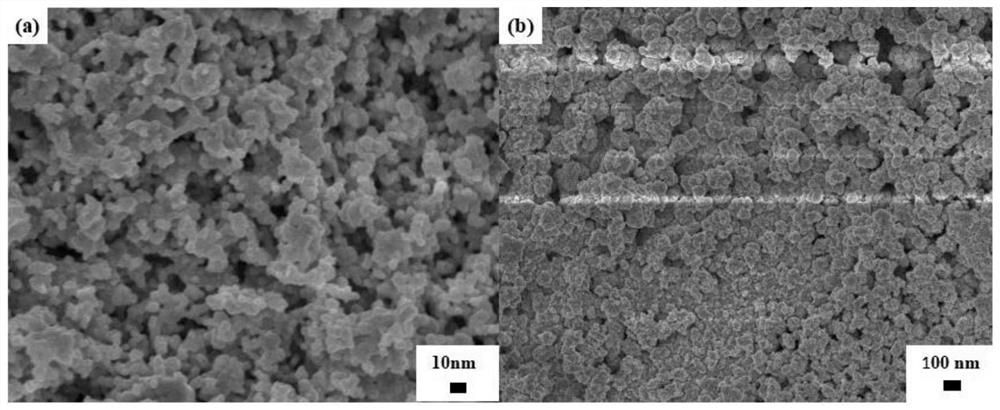

[0059]2) Preparation of bifunctional thin film layer: Dissolve zinc acetate and diethanolamine in absolute ethanol at a concentration of 0.1mol / L, stir at 60°C for 30min, spin-coat on a glass substrate and place in a 400°C Heat treatment on the heating plate for 20-30 minutes, repeat the spin coating and heat treatment 3 times to obtain the ZnO seed layer, and then wash the surface with absolute ethanol and deionized water to remove exce...

Embodiment 2

[0067] A method for preparing a double-functional electron transport layer inverted structure quantum dot light-emitting device, comprising the following steps:

[0068] 1) Preparation of the glass substrate: Cut the glass into a size of 20×16mm to obtain a glass substrate, place it in a solution mixed with detergent for ultrasonic cleaning for 15 minutes, then place it in acetone for 20 minutes, and then place it in ethanol for cleaning 15 minutes, and finally placed in deionized water for ultrasonic cleaning for 20 minutes, and then dried for later use.

[0069] 2) Preparation of bifunctional thin film layer: Dissolve zinc acetate and diethanolamine in absolute ethanol at a concentration of 0.1mol / L, stir at 60°C for 30min, spin-coat on a glass substrate and place in a 400°C Heat treatment on the heating plate for 20-30 minutes, repeat the spin coating and heat treatment 3 times to obtain the ZnO seed layer, and then wash the surface with absolute ethanol and deionized water...

Embodiment 3

[0077] A method for preparing a double-functional electron transport layer inverted structure quantum dot light-emitting device, comprising the following steps:

[0078] 1) Preparation of the glass substrate: Cut the glass into a size of 20×16mm to obtain a glass substrate, place it in a solution mixed with detergent for ultrasonic cleaning for 20 minutes, then place it in acetone for 10 minutes, and then place it in ethanol for cleaning 20min, and finally ultrasonic cleaning in deionized water for 30min, drying after cleaning for later use.

[0079] 2) Preparation of bifunctional thin film layer: Dissolve zinc acetate and diethanolamine in absolute ethanol at a concentration of 0.1mol / L, stir at 60°C for 30min, spin-coat on a glass substrate and place in a 400°C Heat treatment on the heating plate for 20-30 minutes, repeat the spin coating and heat treatment 3 times to obtain the ZnO seed layer, and then wash the surface with absolute ethanol and deionized water to remove exc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com