Method for preparing ultrathin pinhole-free dielectric films

A dielectric film and ultra-thin film technology, applied in the field of preparing ultra-thin pinhole-free dielectric films, can solve the problems of affecting the dielectric properties of the gate layer, poor uniformity of the dielectric film, and large particle size of the target material, etc. Large-area controllable thickness and uniformity, no pinhole defects, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0035] The metal oxide dielectric film Ta 2 o 5 Take as an example to illustrate the specific operation and preparation process.

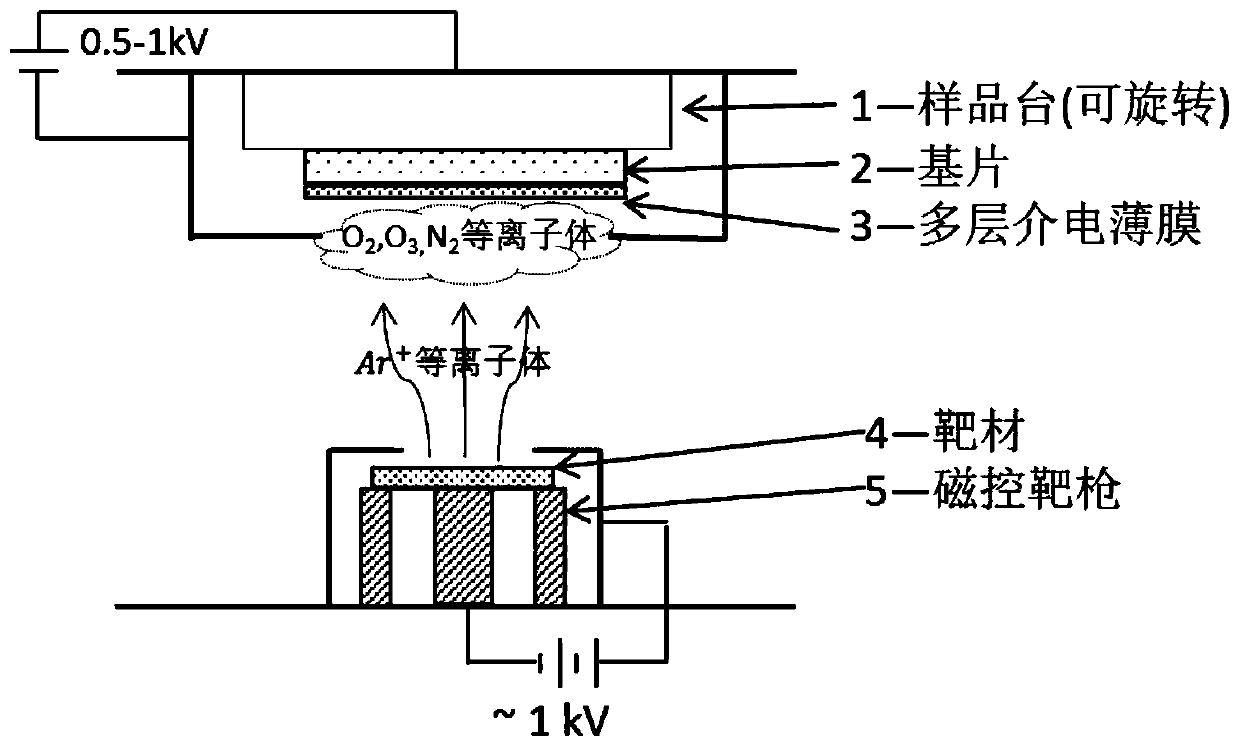

[0036] The magnetron sputtering apparatus used in this embodiment is divided into a main cavity for film growth and an attached cavity for pre-stage sample introduction, Si / SiO 2 (300nm) substrates are delivered to the main chamber of magnetron sputtering through the front-stage sample feeding chamber. The first step is to deposit metal tantalum film: the vacuum degree on the back of the main cavity reaches 2*10 -8 After the Torr is below, open the gas flow meter and feed pure Ar gas into the magnetron sputtering apparatus to stabilize the air pressure in the main chamber at 3.8*10 -3 torr; turn on the DC magnetron sputtering power supply and set the output power to 25 watts, and the deposition rate of tantalum detected by the film thickness detector is 0.023nm / s; ) the substrate is rotated directly above the tantalum target for deposition and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com