Deodorization method in ester synthesis

A technology of esters and polyglycerol esters, which is applied in the field of deodorization in the synthesis of esters, can solve the problems of prolonged reaction time, aggravated odor of polymerization products, unpleasant odor of polyglycerol esters, etc., to achieve environmental and human safety protection, Effects of reducing water consumption and water discharge, and solving unpleasant odors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of deodorization method in ester synthesis, is characterized in that, comprises the following steps:

[0035] S1. Carry out the synthetic reaction of polyglycerol ester in the reaction kettle by means of staged heating;

[0036] S2. In the later stage of the reaction, adjust the vacuum inside the reactor to be -0.06-0.099MPa;

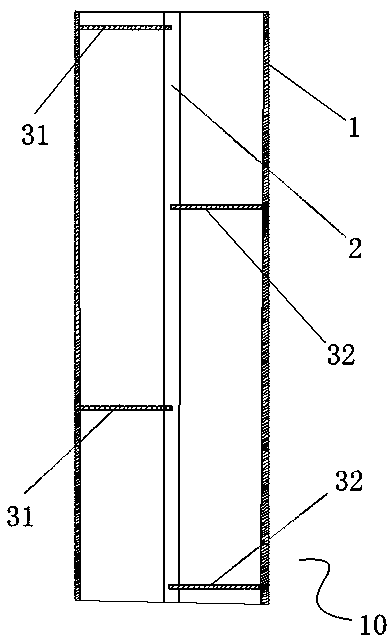

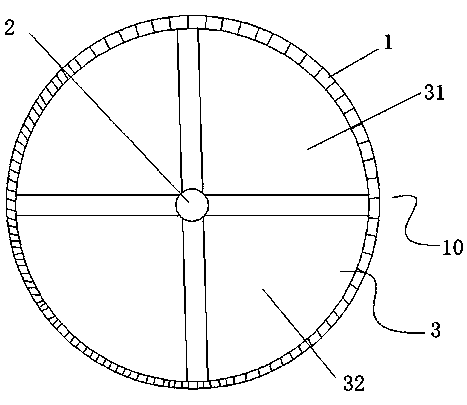

[0037] S3. In the exhaust stage, exhaust through the air riser and recover some materials;

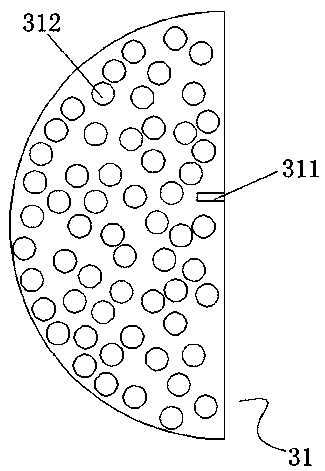

[0038] In step S3, the unpleasant smell is removed by the tray group arranged in the gas riser.

[0039] Further, in step S2, the vacuum degree is -0.01MPa.

[0040] Further, in step S1, the processing method of stepwise heating is as follows: polyglycerol is added to the reactor, the temperature is raised to 50°C, a basic catalyst is added, the temperature is raised to 80°C with stirring, and fatty acid is added to react when the temperature is 60°C. Raise the temperature to 180°C and keep it for 0.5 hours, then slowly raise the temperature to ...

Embodiment 2

[0057] A kind of deodorization method in ester synthesis, is characterized in that, comprises the following steps:

[0058] S1. Carry out the synthetic reaction of polyglycerol ester in the reaction kettle by means of staged heating;

[0059] S2. In the later stage of the reaction, adjust the vacuum inside the reactor to be -0.06-0.099MPa;

[0060] S3. In the exhaust stage, exhaust through the air riser and recover some materials;

[0061] In step S3, the unpleasant smell is removed by the tray group arranged in the gas riser.

[0062] Further, in step S2, the vacuum degree is 0.06MPa.

[0063] Further, in step S1, the processing method of stepwise heating is as follows: adding polyglycerol to the reactor, raising the temperature to 105°C, adding a basic catalyst, stirring and raising the temperature to 180°C, and adding fatty acid to react when the temperature is 130°C, Raise the temperature to 230°C and keep it for 1 hour, then slowly raise the temperature to 298°C for ra...

Embodiment 3

[0071] A kind of deodorization method in ester synthesis, is characterized in that, comprises the following steps:

[0072] S1. Carry out the synthetic reaction of polyglycerol ester in the reaction kettle by means of staged heating;

[0073] S2. In the later stage of the reaction, adjust the vacuum inside the reactor to be -0.06MPa;

[0074] S3. In the exhaust stage, exhaust through the air riser and recover some materials;

[0075] In step S3, the unpleasant smell is removed by the tray group arranged in the gas riser.

[0076] Further, in step S1, the processing method of stepwise heating is as follows: polyglycerin is added to the reactor, the temperature is raised to 65°C, a basic catalyst is added, the temperature is raised to 95°C with stirring, and fatty acid is added to react when the temperature is 75°C. Raise the temperature to 195°C and keep it for 0.6 hours, then slowly raise the temperature to 260°C for rapid reaction, adjust the vacuum degree inside the reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com