Method for extracting nerve growth factor

A technology of nerve growth factor and extraction method, which is applied in the field of extraction of nerve growth factor, can solve problems such as complex steps, unfavorable large-scale preparation, low yield, etc., achieve simple extraction method, improve sample yield and sample activity, avoid adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

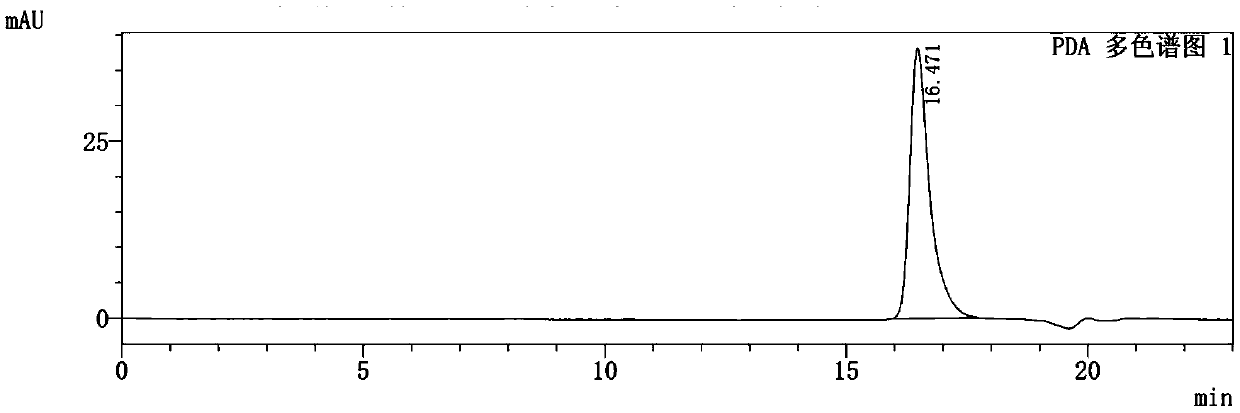

Image

Examples

Embodiment 1

[0057] Example 1, the extraction of human nerve growth factor in the submandibular gland of transgenic mice

[0058] 1. Homogenate: Take the submandibular gland of transgenic mice expressing human nerve growth factor, mix the submandibular gland with purified water pre-cooled to 4°C at a mass volume ratio of 1g:4ml, and fully crush it with a high-speed tissue grinder to obtain a homogenate. The homogenate was centrifuged at 11000×g and 4°C for 30 min, and the centrifuged supernatant was collected.

[0059] 2. Acidification centrifugation: Add acid buffer 1mol / L acetate buffer solution (pH3.8) to the centrifugal supernatant obtained in step 1 to quickly reduce the pH to 4.0, then add NaCl solid to make the final concentration of NaCl 0.2mol / L, after standing for about 5 minutes, centrifuge at 10,000×g for 30 minutes at 4°C to obtain the acid hydrolysis supernatant.

[0060] 3. Cation exchange chromatography: CM Sepharose Fast Flow packing column, fully equilibrated with 0.05m...

Embodiment 2 and 3

[0088] Repeat the steps of Example 1, the difference is only that the parameters provided in Table 3 are used to carry out cation exchange chromatography and hydrophobic chromatography:

[0089] table 3

[0090]

[0091]

Embodiment 4

[0097] Repeat the steps of Example 1, the only difference is that the following steps are inserted after the hydrophobic chromatography step:

[0098] The Superdex 75 prep grade chromatographic column was fully balanced with pH6.8, 0.05mol / L phosphate-0.15mol / L sodium chloride buffer solution, and the sample was loaded, and the collection began when the number displayed at 280nm on the ultraviolet detector began to rise, and the drop Stop collecting the target protein peak at baseline and obtain a gel filtration chromatography sample.

[0099] The index detection of the hNGF extract of test example 3, embodiment 4

[0100] According to the method of Test Example 1, various indicators of the hNGF extract of Example 4 were detected, and the results are shown in Table 5.

[0101] table 5

[0102] Test items

[0103] It can be seen from Table 5 that compared with Example 1, the process of Example 4 has significantly reduced residual host protein and DNA residues in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com