Preparation method and application of two-dimensional multi-element metallic nano material

A technology of multiple metals and nanomaterials, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve the effects of controllable size, adjustable components, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) In a 25 ml reaction flask, add 90 mg citric acid, 20 mg potassium bromide, 30 mg polyvinylpyrrolidone, 16 mg palladium acetylacetonate, 8 mg platinum acetylacetonate, 5 mg copper acetylacetonate, and 10 ml N-N dimethylformamide at room temperature Stir for 1h;

[0035] 2) Add 25mg of molybdenum hexacarbonyl, put it in an oil bath at 80°C for 3h, then naturally raise the temperature to 150°C and keep it for 3h. After the reaction is finished, cool down to room temperature naturally, wash and centrifuge several times with a mixture of ethanol and acetone for later use, and obtain a two-dimensional Ultrathin palladium-platinum-copper ternary alloy nanorings.

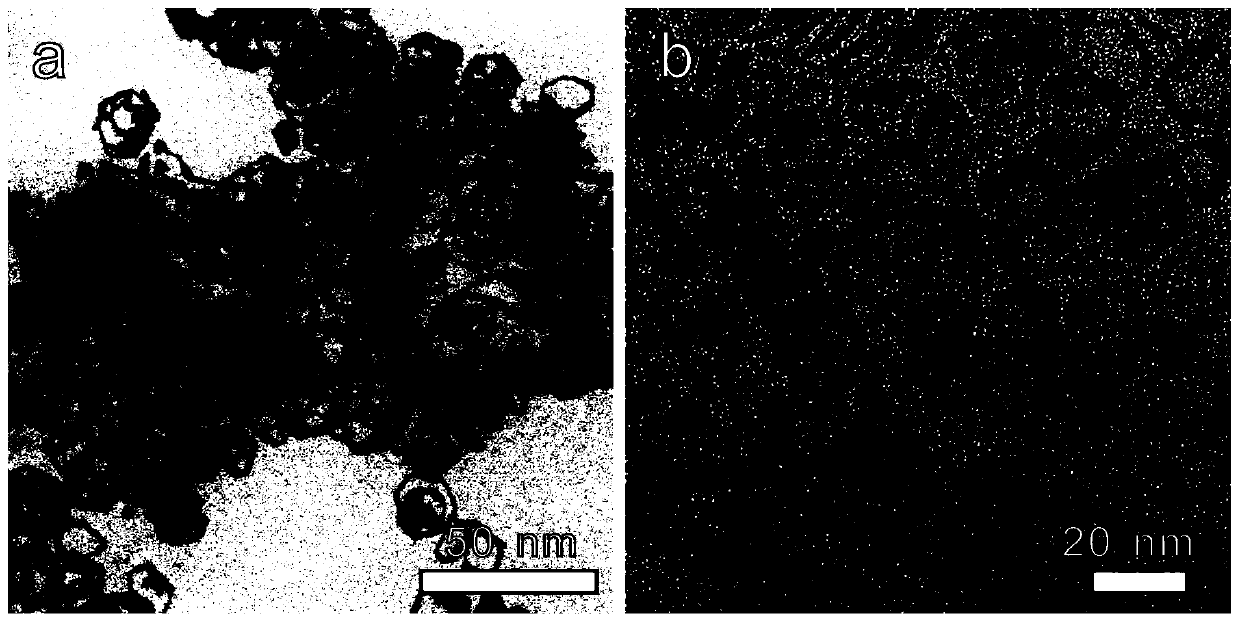

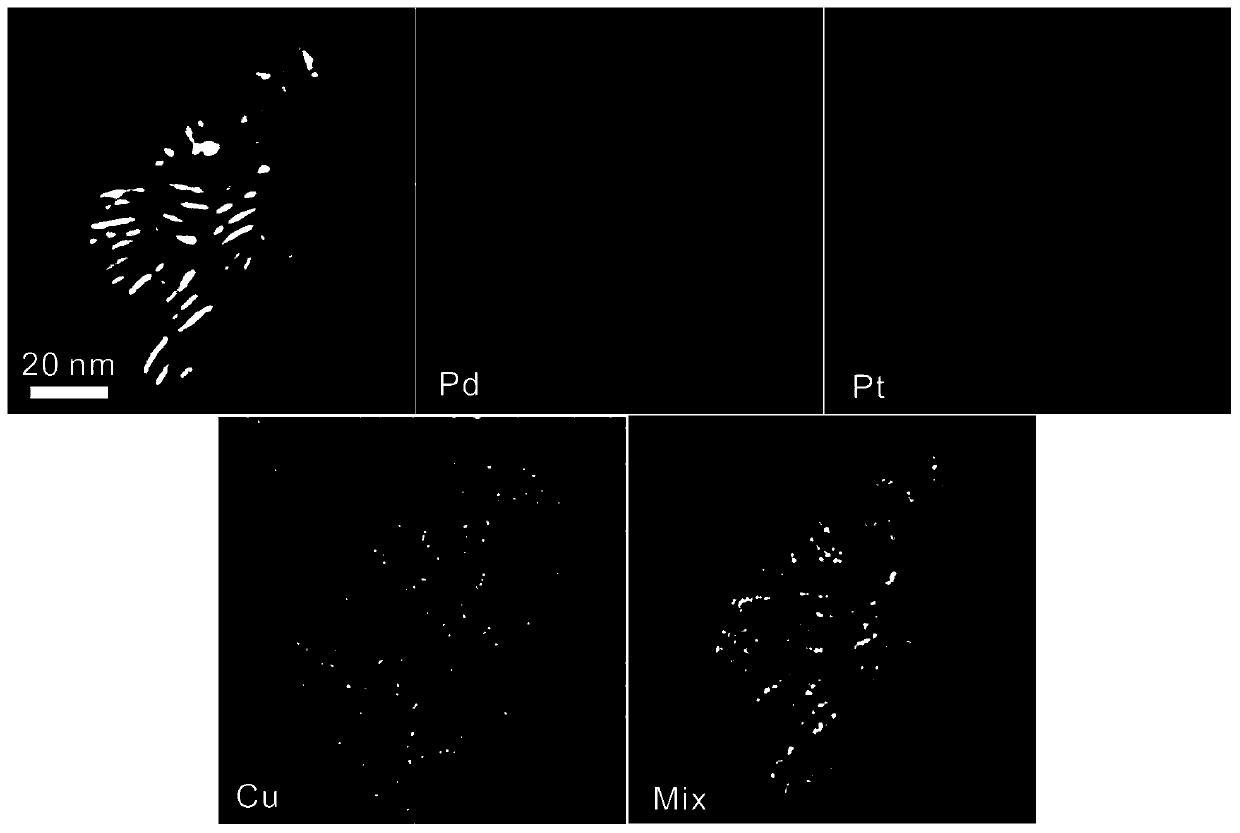

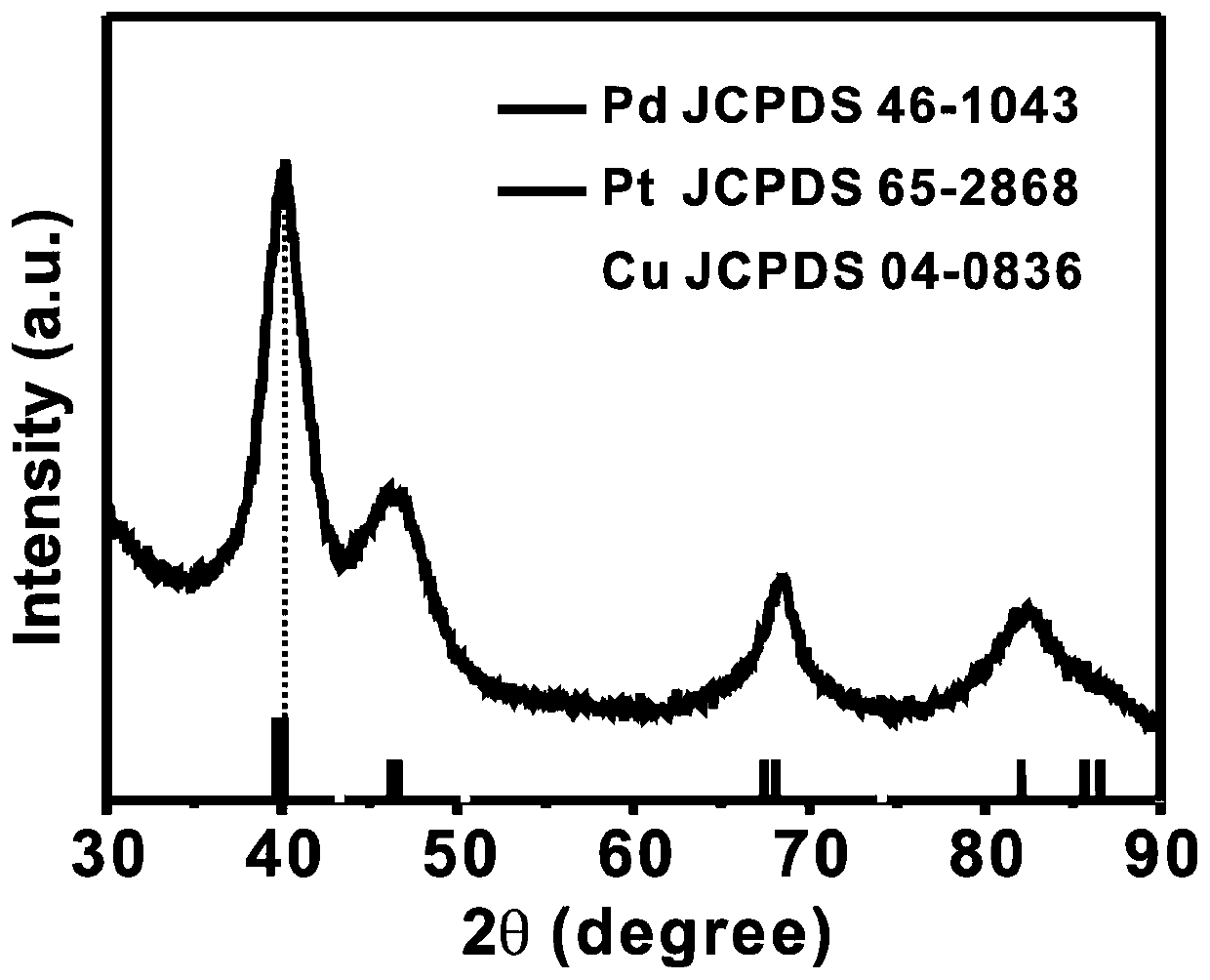

[0036] The morphology, composition, and microstructure of the product are systematically studied by modern nanometer testing and analysis techniques such as TEM, HAADF-STEM, and XRD. TEM( figure 1 a, b) The characterized product is an ultra-thin two-dimensional hexagonal ring structure with 100% purity, the side...

Embodiment 2

[0038] 1) In a 25 ml reaction flask, add 90 mg citric acid, 20 mg potassium bromide, 30 mg polyvinylpyrrolidone, 16 mg palladium acetylacetonate, 8 mg platinum acetylacetonate, 5 mg copper acetylacetonate, and 10 ml N-N dimethylformamide at room temperature Stir for 1h;

[0039] 2) Add 75mg of molybdenum hexacarbonyl, put it in an oil bath at 80°C for 3h, then naturally raise the temperature to 150°C and keep it for 3h, after the reaction is finished, cool down to room temperature naturally, wash and centrifuge several times with a mixture of ethanol and acetone to obtain a two-dimensional super Thin palladium-platinum-copper ternary alloy nanosheets.

[0040] The morphology, composition, and microstructure of the product are systematically studied by modern nanometer testing and analysis techniques such as TEM, HAADF-STEM, and XRD. TEM, HAADF-STEM ( Figure 4 a, b) The characterized product is an ultra-thin two-dimensional hexagonal sheet structure with 100% purity, the hex...

Embodiment 3

[0042] 1) In a 25 ml reaction flask, add 90 mg of citric acid, 20 mg of potassium bromide, 30 mg of polyvinylpyrrolidone, 16 mg of palladium acetylacetonate, 8 mg of platinum acetylacetonate, and 10 ml of N-N dimethylformamide, and stir at room temperature for 1 hour;

[0043] 2) Add 75 mg of molybdenum hexacarbonyl, put it in an oil bath at 80°C for 3 hours, then raise the temperature to 150°C and keep it for 3 hours. After the reaction, cool down to room temperature naturally, wash and centrifuge with a mixture of ethanol and acetone for several times to obtain a two-dimensional ultrathin film. Palladium-platinum binary alloy nanosheets, high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM), energy spectrum analysis surface scanning (EDS) ( Figure 7 ) characterized it as a high-yield ultrathin palladium-platinum bimetallic two-dimensional sheet structure, further confirming the two-component characteristics of the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com