Sea cucumber peptide and production method thereof

A production method and technology of sea cucumber peptide, applied in the field of sea cucumber peptide and its production, can solve the problems of low enzymatic hydrolysis efficiency, cumbersome steps, easy moisture absorption and agglomeration, etc., achieve low free amino acid content, improve enzymatic hydrolysis efficiency, and not easy to absorb damp caking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

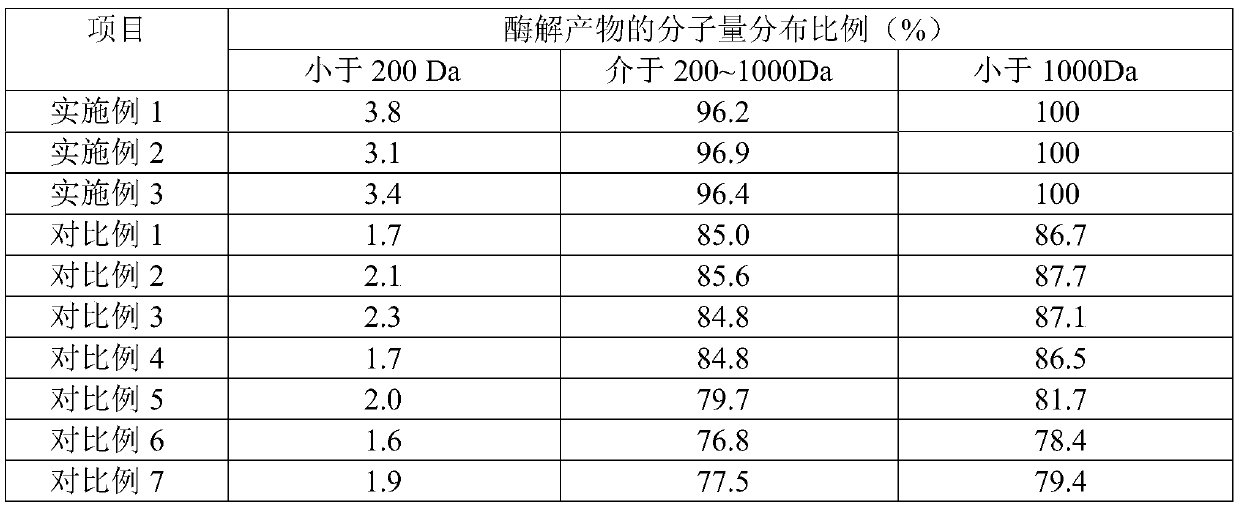

Examples

Embodiment 1

[0044] (1) Raw material pretreatment: clean the sea cucumber body wall, add 1 times the quality of water, and mash the tissue into sea cucumber homogenate;

[0045] (2) Heat treatment: heat the sea cucumber homogenate in hot water at 100°C for 30 minutes, then cool it down to 50-55°C to obtain a denatured sea cucumber solution;

[0046] (3) Enzymolysis: Add 0.1% (w / w) high-efficiency compound enzyme preparation of raw material weight to the denatured sea cucumber solution, mix evenly, and enzymatically hydrolyze for 1 hour under natural conditions without adjusting the pH value and controlling the temperature , to prepare a sea cucumber peptide solution; the high-efficiency compound enzyme preparation is composed of the following components in mass percentage: 30% compound protease, 30% acid protease, 30% neutral protease, 7% animal proteolytic enzyme and enzyme Activator 3%. The enzyme activator consists of reducing agent dithiothreitol, β-mercaptoethanol and divalent metal ...

Embodiment 2

[0052] (1) Raw material pretreatment: clean the sea cucumber body wall, add 2 times the quality of water, and mash the tissue into sea cucumber homogenate;

[0053] (2) Heat treatment: heat the sea cucumber homogenate in hot water at 100°C for 30 minutes, then cool it down to 50-55°C to obtain a denatured sea cucumber solution;

[0054] (3) Enzymolysis: Add 0.1% (w / w) high-efficiency compound enzyme preparation of raw material weight to the denatured sea cucumber solution, mix evenly, and enzymatically hydrolyze for 1 hour under natural conditions without adjusting the pH value and controlling the temperature , to prepare sea cucumber peptide solution; the high-efficiency compound enzyme preparation is composed of the following components in mass percentage: compound protease 35%, acid protease 27.5%, neutral protease 27.5%, animal proteolytic enzyme 7.5% and enzyme Activator 2.5%. The enzyme activator consists of reducing agent β-mercaptoethanol and divalent metal ion Mg 2+...

Embodiment 3

[0060] (1) Raw material pretreatment: clean the sea cucumber body wall, add 3 times the quality of water, and mash the tissue into sea cucumber homogenate;

[0061] (2) Heat treatment: heat the sea cucumber homogenate in hot water at 100°C for 30 minutes, then cool it down to 50-55°C to obtain a denatured sea cucumber solution;

[0062] (3) Enzymolysis: Add 0.1% (w / w) high-efficiency compound enzyme preparation of raw material weight to the denatured sea cucumber solution, mix evenly, and enzymatically hydrolyze for 1 hour under natural conditions without adjusting the pH value and controlling the temperature , to prepare a sea cucumber peptide solution; the high-efficiency compound enzyme preparation is composed of the following components in mass percentage: 40% compound protease, 25% acid protease, 25% neutral protease, 8% animal proteolytic enzyme and enzyme Activator 2%. The enzyme activator consists of reducing agent dithiothreitol and divalent metal ion Mg 2+ , Zn 2+...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com