Process method for modified collaborative preparation of egg white powder through enzymolysis and phosphorylation

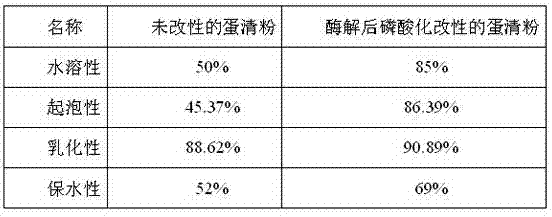

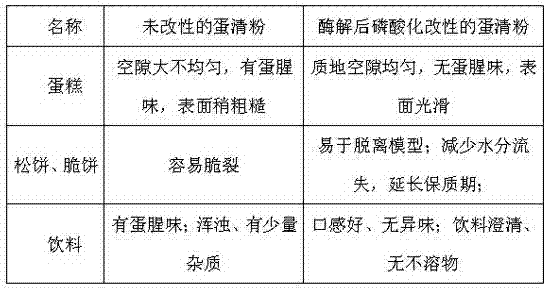

A process method and phosphorylation technology, applied in the fields of food preparation, application, food science, etc., can solve the problems that the protein cannot be fully utilized, increase the production cost of the product, waste protein resources, etc., so as to improve the utilization rate of raw materials and improve the quality of finished products. , good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A process for synergistically preparing egg white powder by enzymolysis and phosphorylation modification, comprising the following steps:

[0052] (1) Material selection: choose fresh eggs;

[0053] (2) Cleaning: clean the egg surface;

[0054] (3) Measure its water content and protein content: put a small amount of egg white in a petri dish in a drying oven for a certain period of time, measure its water content; and use semi-micro Kjeldahl method to measure its protein content;

[0055] (4) Egg white separation: open the egg, separate the egg white and egg yolk, and collect the egg white;

[0056] (5) Dilution with distilled water: dilute the egg white with distilled water to 10% egg white liquid;

[0057] (6) Adjust pH and temperature: adjust the temperature of the water bath to 55°C, and adjust the pH of the egg white solution to 7.0 with sodium hydroxide solution or hydrochloric acid solution;

[0058] (7) Constant temperature enzymolysis: Add 6000U / g compound p...

Embodiment 2

[0067] (1) Material selection: choose fresh eggs;

[0068] (2) Cleaning: clean the egg surface;

[0069] (3) Measure its water content and protein content: put a small amount of egg white in a petri dish in a drying oven for a certain period of time, measure its water content, and measure its protein content by semi-micro Kjeldahl method;

[0070] (4) Egg white separation: open the egg, separate the egg white and egg yolk, and collect the egg white;

[0071] (5) Dilution with distilled water: dilute the egg white with distilled water to 10% egg white liquid;

[0072] (6) Adjust pH and temperature: adjust the temperature of the water bath to 53°C, and adjust the pH of the egg white solution to 7.2 with sodium hydroxide solution or hydrochloric acid solution;

[0073] (7) Constant temperature enzymolysis: add 5500U / g compound protease to the egg white solution for enzymolysis, control the temperature at 53°C during the enzymolysis process, shake and mix once every 30min, enzym...

Embodiment 3

[0082] (1) Material selection: choose fresh eggs;

[0083] (2) Cleaning: clean the egg surface;

[0084] (3) Measure its water content and protein content: put a small amount of egg white in a petri dish in a drying oven for a certain period of time, measure its water content, and measure its protein content by semi-micro Kjeldahl method;

[0085] (4) Egg white separation: open the egg, separate the egg white and egg yolk, and collect the egg white;

[0086] (5) Dilution with distilled water: dilute the egg white with distilled water to 10% egg white liquid;

[0087] (6) Adjust pH and temperature: adjust the temperature of the water bath to 55°C, and adjust the pH of the egg white solution to 7.3 with sodium hydroxide solution or hydrochloric acid solution;

[0088] (7) Constant temperature enzymolysis: add 6000U / g compound protease to the egg white solution for enzymolysis, control the temperature at 55°C during the enzymolysis process, shake and mix once every 30min, enzym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com