Preparation method of silicon-based composite material for lithium ion power battery

A technology of silicon-based composite materials and power batteries, which is applied in battery electrodes, secondary batteries, circuits, etc., to prevent pulverization, avoid high economic costs, and solve the effects of dispersion and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

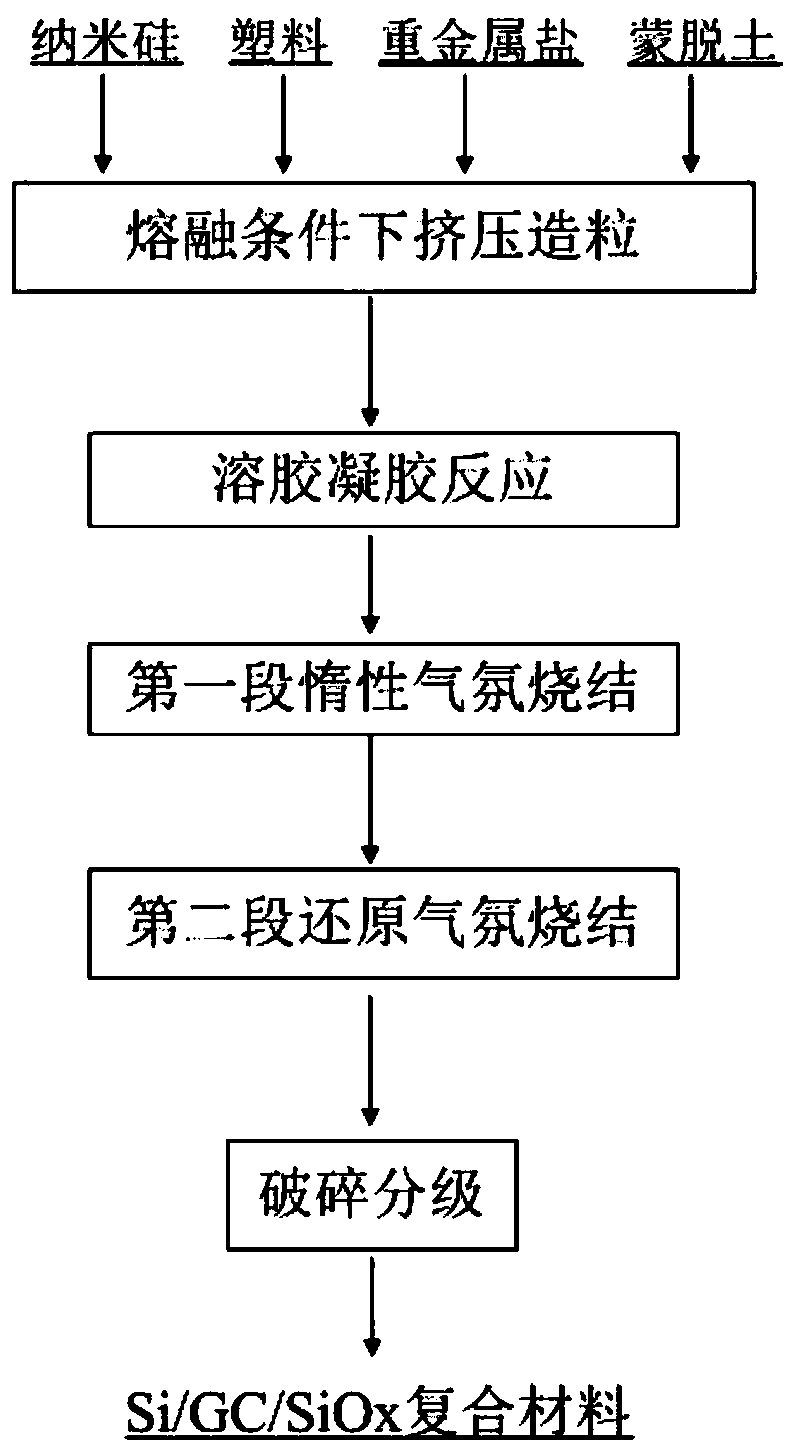

[0043] A kind of preparation method of silicon-based composite material for lithium-ion power battery of the present invention, technological process is figure 1 , including the following steps:

[0044] (1) After mixing 1g nano-silicon, 50g plastics (polypropylene, PP), 0.56g nickel chloride and 5g montmorillonite by mechanical grinding, place them in a twin-screw extruder to control the melting conditions, Control the screw speed of the extruder to 30rpm and stir for 6h, control the processing temperature of the extruder to 220°C, extrude and granulate, cool to room temperature and take it out to obtain a nano-silicon / plastic / montmorillonite composite material;

[0045] (2) Dissolve 1.5ml of Triton X2100 and 1.5g of hexadecyltrimethylquaternary ammonium bromide in 100ml of 1mol / L hydrochloric acid solution until all the surfactants are dissolved and the solution becomes clear, then add 0.1mol of nano Silicon / plastic / montmorillonite composite material, control the molar rati...

Embodiment 2

[0050] A method for preparing a silicon-based composite material for a lithium-ion power battery of the present invention comprises the following steps:

[0051] (1) After mixing 1g nano-silicon, 10g plastic (polypropylene, PP), 0.13g nickel sulfate and 2g montmorillonite by mechanical grinding, place them in a twin-screw extruder, control the melting conditions, and control The screw speed of the extruder was 100rpm and stirred for 10h, the processing temperature of the extruder was controlled to be 270°C, extruded and granulated, cooled to room temperature and taken out to obtain a nano-silicon / plastic / montmorillonite composite material;

[0052] (2) Dissolve 1ml of OP-10 and 1g of trialkylammonium chloride in 200ml of 5mol / L hydrochloric acid solution until all the surfactants are dissolved and the solution becomes clear, then add 0.1mol of nano-silicon / plastic / montane under stirring Remove the soil composite material, control the molar ratio of n(HCl) / n(nano-silicon / plasti...

Embodiment 3

[0057] A method for preparing a silicon-based composite material for a lithium-ion power battery of the present invention comprises the following steps:

[0058] (1) After mixing 1g nano-silicon, 25g plastic (polypropylene, PP), 0.29g nickel acetate and 3g montmorillonite by mechanical grinding, place them in a twin-screw extruder, control the melting conditions, and control The screw speed of the extruder was 50 rpm and stirred for 8 hours, the processing temperature of the extruder was controlled to be 250° C., extruded and granulated, cooled to room temperature and taken out to obtain a nano-silicon / plastic / montmorillonite composite material;

[0059] (2) Dissolve 2ml of NP-8.6 and 2g of trialkylmethylammonium chloride in 200ml of 3mol / L hydrochloric acid solution until all surfactants are dissolved and the solution becomes clear, then add 0.15mol of nano silicon / plastic under stirring / montmorillonite composite material, control the molar ratio of n(HCl) / n(nano-silicon / pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com