Bonding structure and forming method thereof

A bonding structure and graphics technology, applied in semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve problems such as increased cost, decreased product reliability, and shortened electromigration life, so as to improve reliability and avoid Reliability deterioration, avoiding the effect of electrical performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

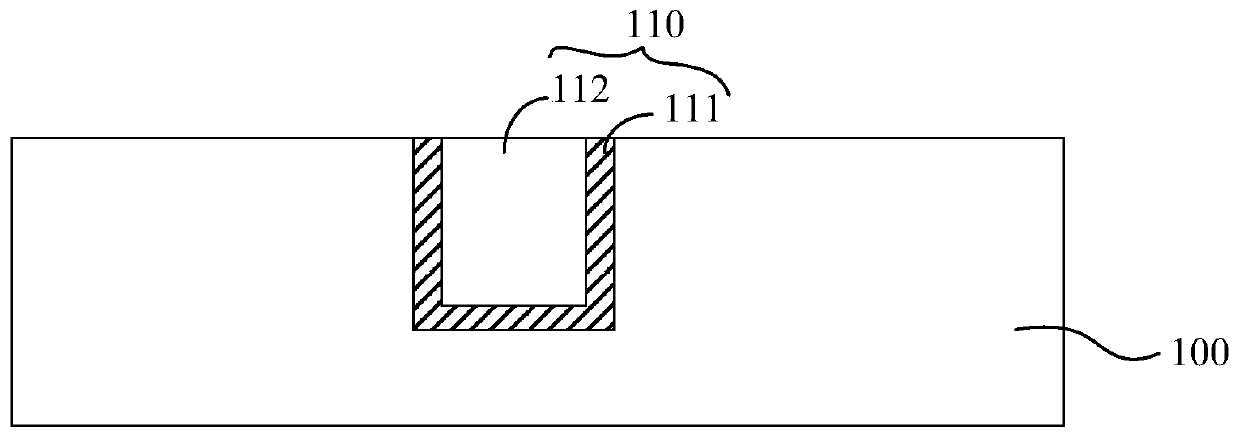

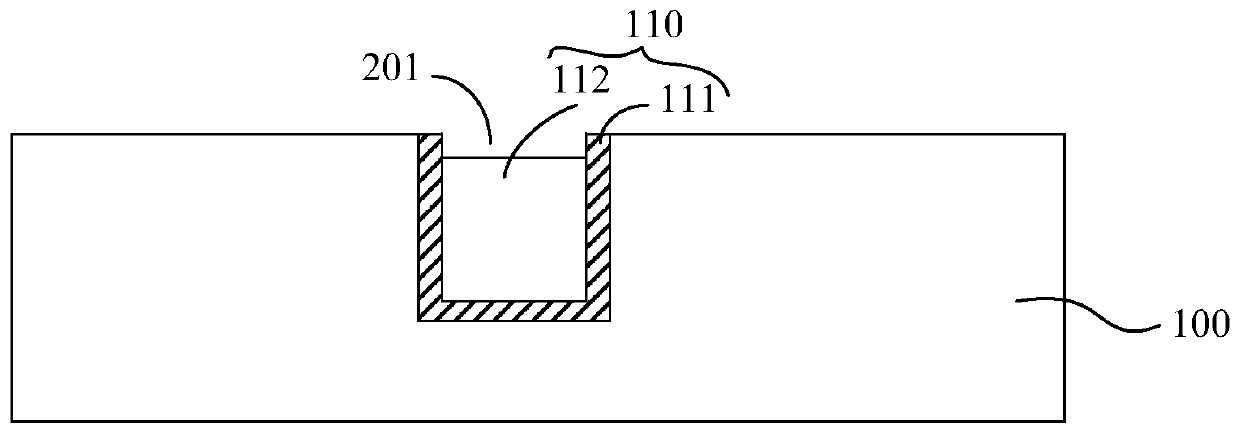

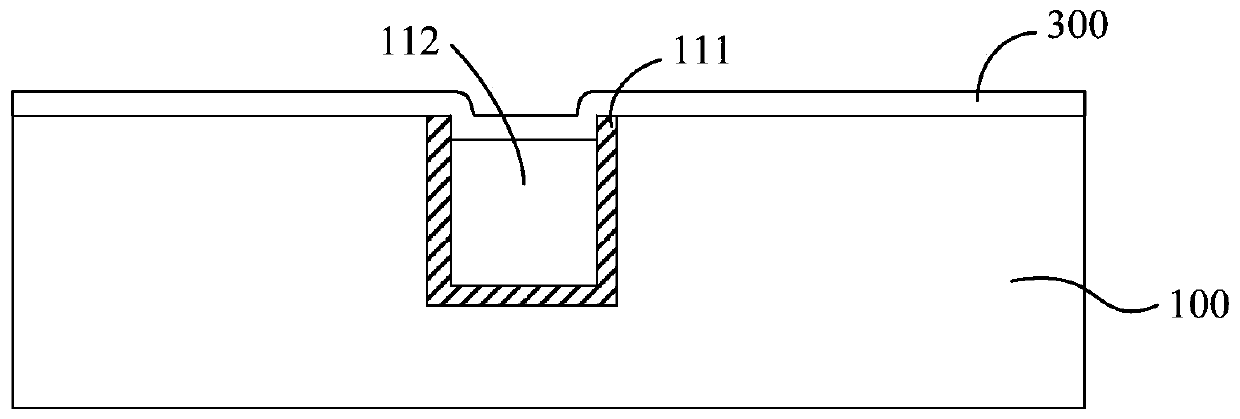

[0026] The specific implementation of the bonding structure provided by the present invention and its forming method will be described in detail below in conjunction with the accompanying drawings.

[0027] In a specific embodiment of the present invention, the method for forming the bonding structure includes: providing two substrates, each of which includes a dielectric layer and a metal interconnection on the exposed top surface within the dielectric layer; The barrier layer is formed on the surface of the metal interconnection at the opposing bonding position of the substrates, and when the metal interconnecting portions are provided at the opposing bonding positions of the two substrates, at least the top surface of the metal interconnecting portion with a larger size is formed. A barrier layer, the barrier layer is a conductive material and can block the diffusion of metal atoms; the surfaces of the two substrates are bonded to each other, and the barrier layer is located...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com