Unsaturated polyester flow coating white primer and preparation process thereof

An unsaturated, whitening technology, applied in polyester coatings, coatings, etc., can solve the problems of poor overall adhesion, easy to peel off, poor paint stability, etc., to achieve not easy to peel off, improve compatibility The effect of improving permeability, penetration and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: a kind of unsaturated polyester flow-coating white primer, each component and its corresponding parts by weight are shown in Table 1, and are prepared by the following steps:

[0046] Step 1, prepare unsaturated polyester resin, mix and heat corresponding parts by weight of maleic anhydride, isophthalic anhydride and propylene glycol, condense and reflux, heat up to 80°C in 15min, and rotate at 200rpm; then The temperature is raised to 160°C in 50min, the rotation speed is 400rpm, and finally the temperature is raised to 195°C in 60min, the rotation speed is 300rpm, and the reaction is maintained for 60min to obtain an unsaturated polyester resin;

[0047] Step 2, mix materials, and sequentially add corresponding parts by weight of polyoxyethylene trisiloxane, alkyl glucamide and epoxy phosphate in the unsaturated polyester resin for high-speed stirring, and the rotating speed is 5000 rpm, and the stirring time is 5000 rpm. For 20min, the mixture was obtai...

Embodiment 2-8

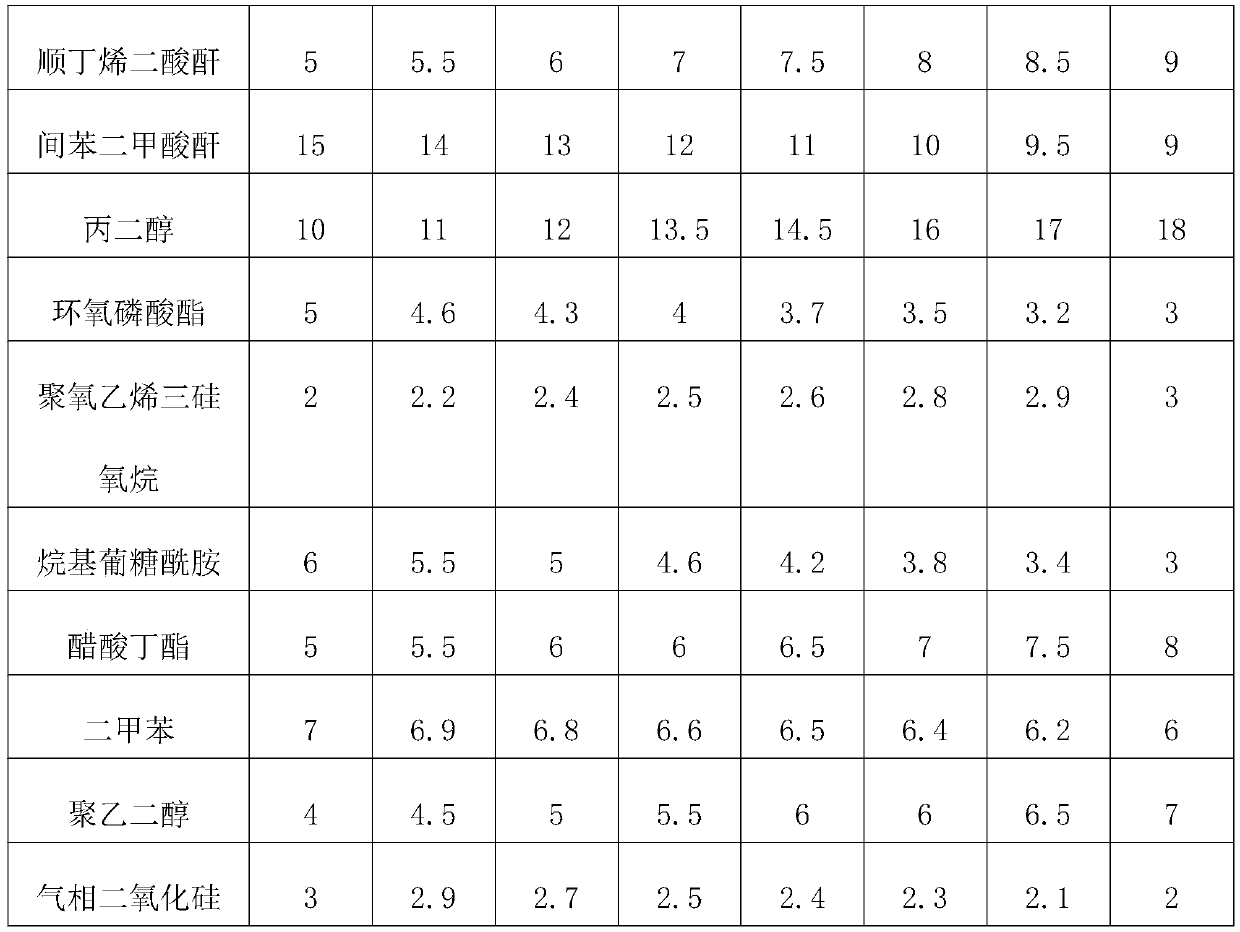

[0049] Example 2-8: An unsaturated polyester flow-coating white primer, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0050] Each component and its parts by weight in the embodiment 1-8 of table 1

[0051]

[0052]

Embodiment 9

[0053] Embodiment 9: a kind of unsaturated polyester spray coating white primer, the difference from embodiment 1 is that step 2 specifically includes the following steps, mixing materials, and sequentially adding corresponding parts by weight to the unsaturated polyester resin 2 parts of polyoxyethylene trisiloxane, 6 parts of alkyl glucamide, 5 parts of epoxy phosphate ester and 3 parts of silica sol are uniformly stirred at a high speed, the rotating speed is 5000 rpm, and the stirring time is 20 min to obtain a mixed solution. material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com