A combination treatment process of sbbr-sbr deep denitrification of landfill leachate

A landfill leachate and treatment process technology, which is applied in the field of landfill leachate SBBR-SBR deep denitrification combined treatment process, can solve the problems of high treatment cost, difficulty in denitrification rate reaching 90%, and low denitrification efficiency, etc. achieve fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

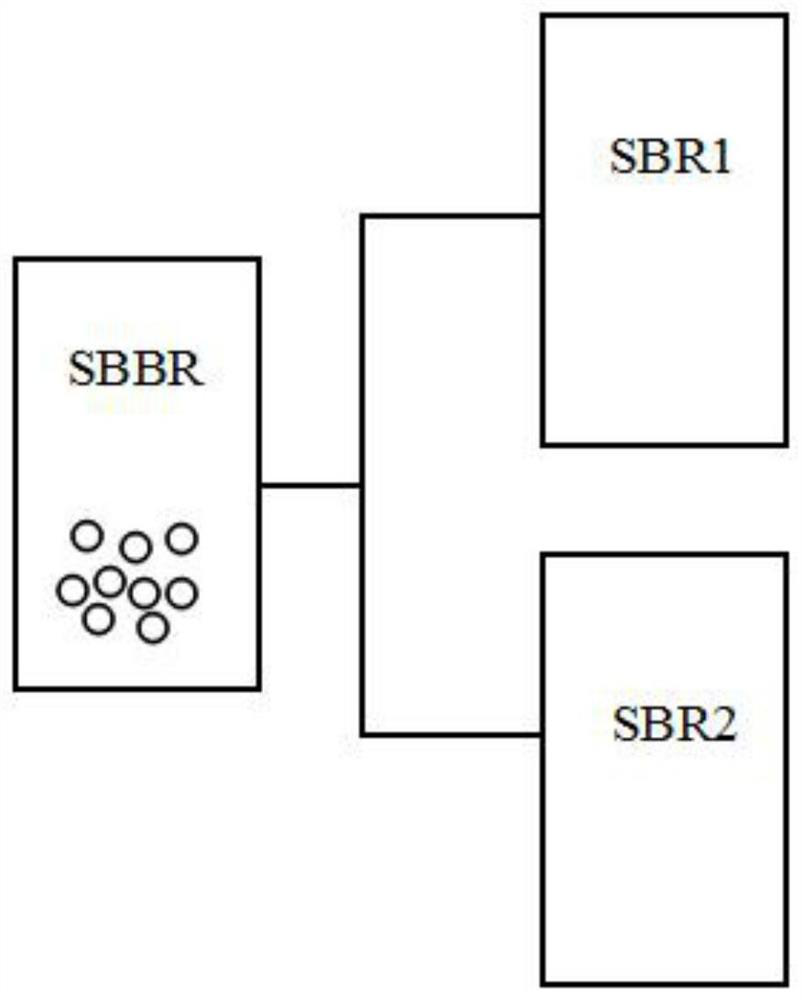

[0022] Example 1 A combined treatment process for landfill leachate SBBR-SBR deep denitrification

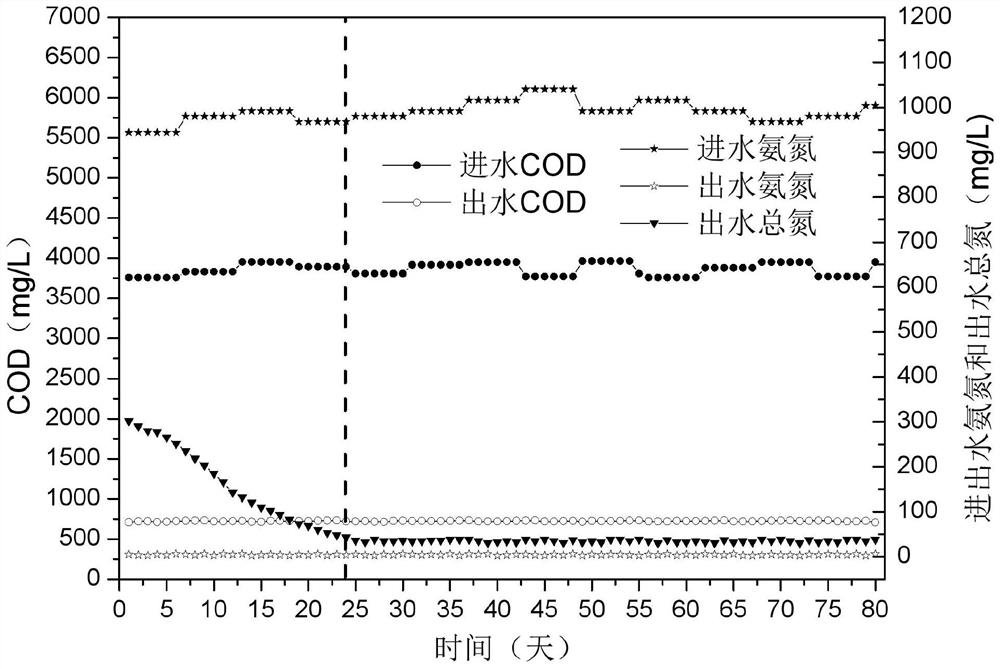

[0023] A landfill leachate SBBR-SBR deep denitrification combined treatment process, including a sequencing batch biofilm reactor (SBBR) and two sequencing batch activated sludge reactors (SBR1 and SBR2), SBBR, SBR1 reactor and The drainage ratio of the SBR2 reactor is 30%, the sludge concentration is 6-8g / L, and the filling ratio of the SBBR filler is 30%; the landfill leachate is treated by the SBBR-SBR deep denitrification combined treatment process, and the leachate Leachate with COD of 3700mg / L±200mg / L and ammonia nitrogen concentration of 900mg / L±100mg / L.

[0024] Described processing technology comprises the steps:

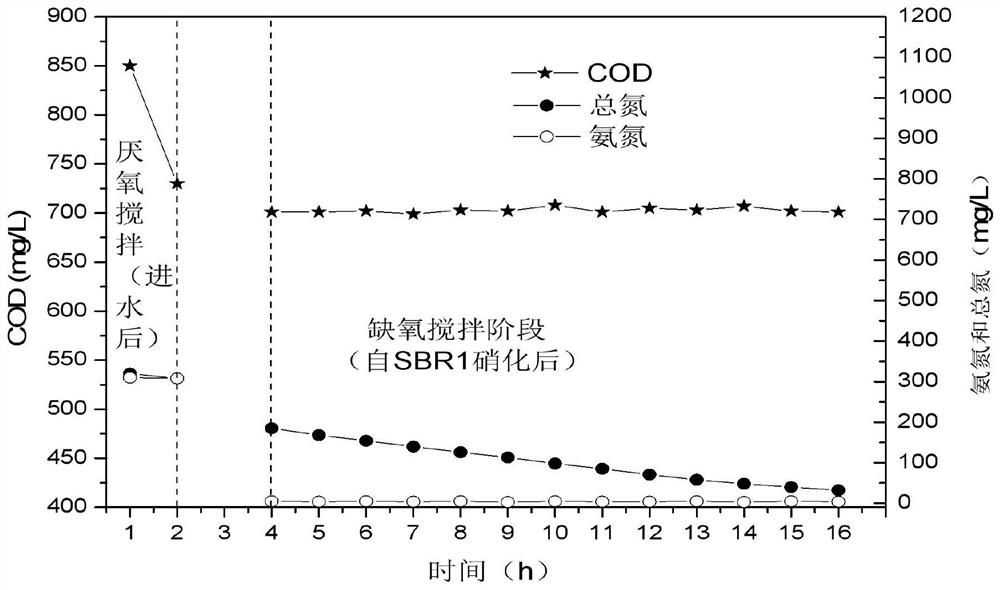

[0025] (1) The SBBR and SBR1 reactors respectively enter the sewage to be treated (i.e. landfill leachate). After the SBBR enters the water, anaerobic stirring is performed. The stirring time of the anaerobic stirring is 1h, and the SBR1 reactor is aerated a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com