Stainless steel powder machining technology

A technology of stainless steel powder and processing technology, applied in the field of powder metallurgy, which can solve the problems of affecting the surface smoothness of powder particles, easily scratching molds, and decarburization of products, and achieve the effect of reducing the risk of being oxidized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of processing technology of stainless steel powder, concrete processing steps are as follows:

[0037] (1) Melting: Add solid stainless steel of the type to be processed into the intermediate frequency furnace, heat to melt the solid stainless steel; then add cullet with smaller particle size into the furnace from the furnace mouth of the intermediate frequency furnace, and melt the surface of the molten liquid Completely cover, covering thickness is 3cm, plays the protective effect of isolating oxygen; Continue to heat and smelt until cullet and solid stainless steel all melt; Wherein, the finer the cullet is, the more favorable the protective effect of blocking air is played to stainless steel, in the present invention The broken glass slag with a particle size of 0.5-1.5cm is used;

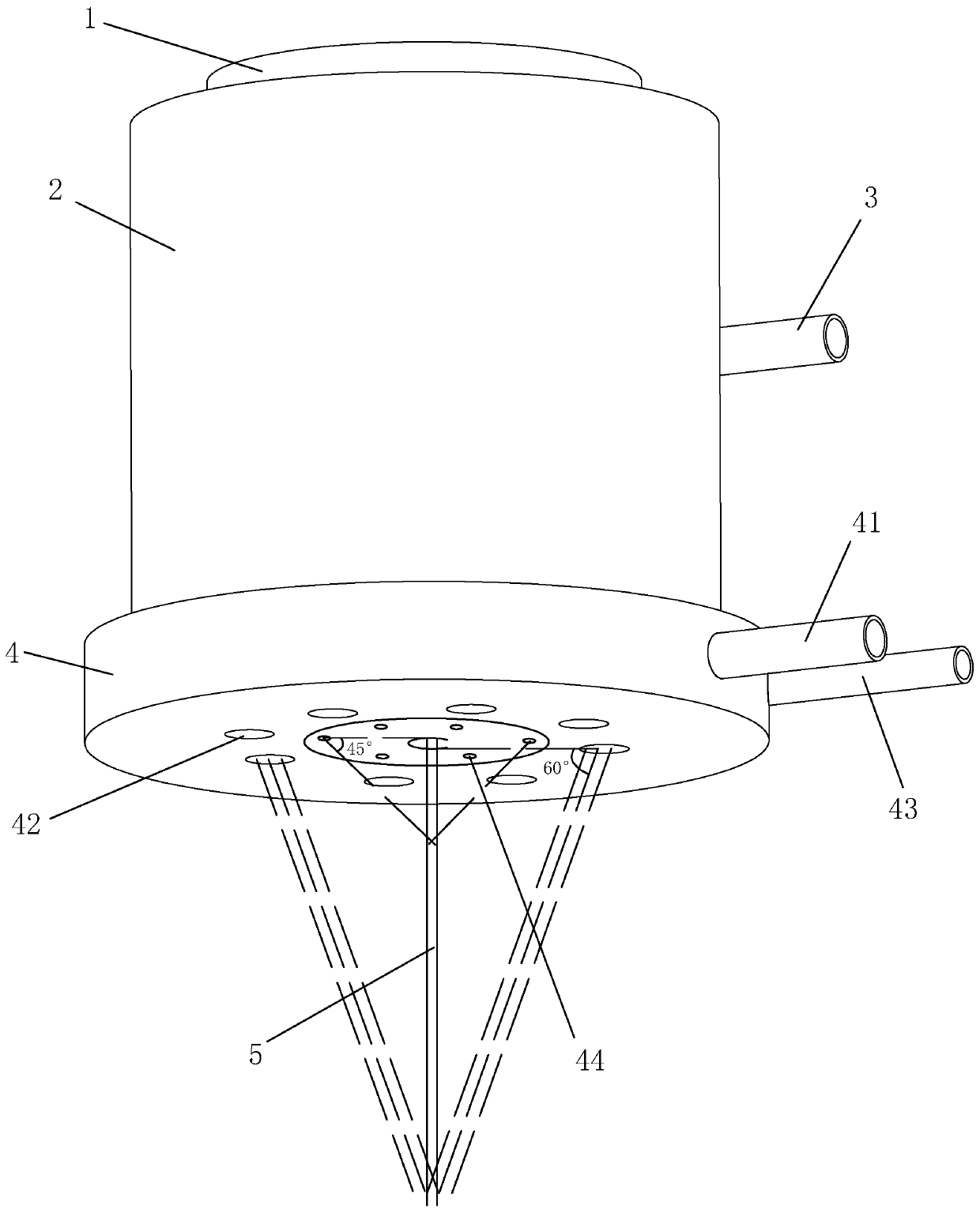

[0038] (2) Water atomization pulverization: such as figure 1 As shown, the tundish in the present invention includes an internal quartz crucible 1 and a heating jacket 2 wrapped ...

Embodiment 2

[0044] The difference between the processing technology of Example 2 and Example 1 is that in step (1), the amount of cullet added is controlled at a thickness of 1 cm, and the rest is consistent with Example 1. The stainless steel powder of Example 2 is obtained, and its oxygen content is measured. It is 1670ppm.

Embodiment 3

[0046] The difference between the processing technology of Example 3 and Example 1 is that in step (1), the amount of cullet added is controlled at a thickness of 2 cm, and the rest is consistent with Example 1. The stainless steel powder of Example 3 is obtained, and its oxygen content is measured. 1700ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com