Residual stress testing method based on profile method, and ancillary device

A residual stress and cutting device technology, applied in the field of residual stress detection, can solve the problem that it is difficult to measure enough contour data for small-sized samples, and achieve the effect of lowering the test threshold, taking into account economy and practicability, and reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

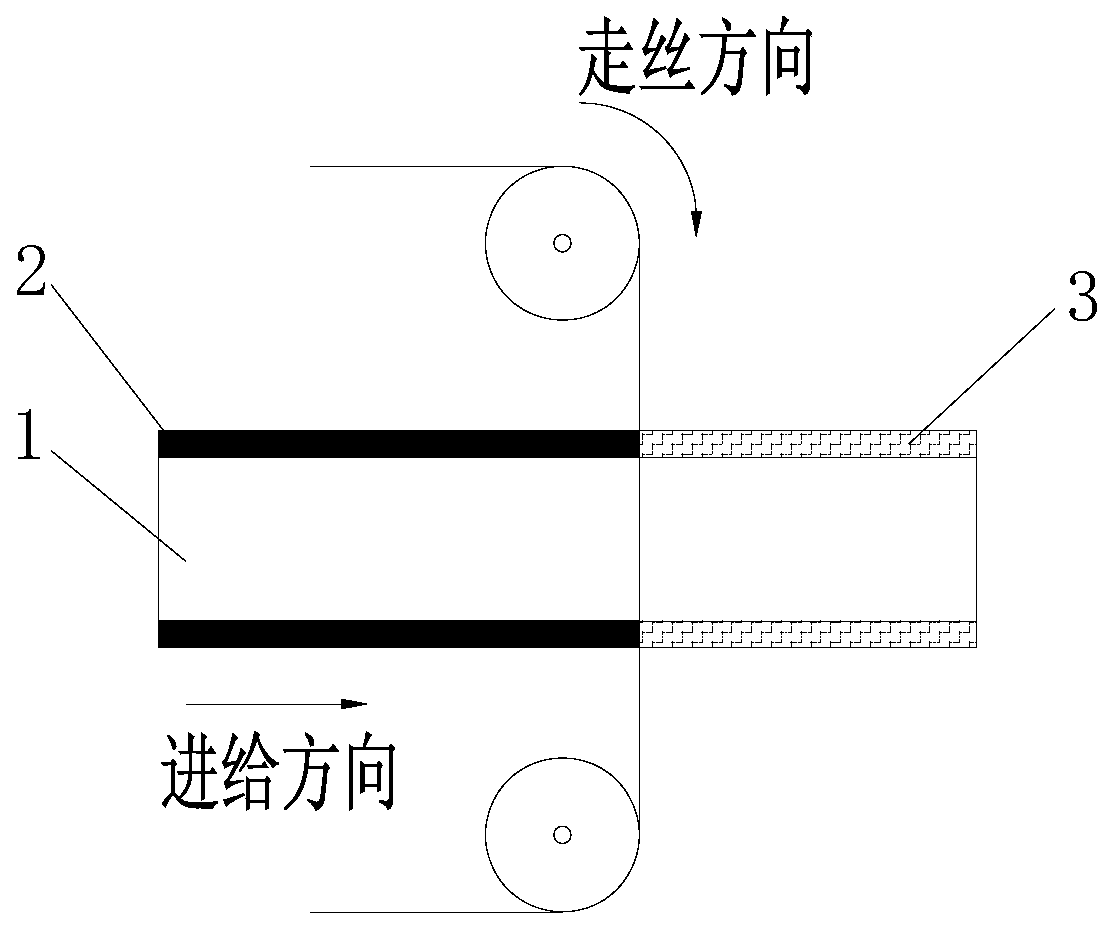

[0066] The invention improves the profile method to test the residual stress, adopts a special linear slow wire cutting device, cuts the sample with the transition zone along the surface to be tested, and uses a laser profiler to scan the cut surface to obtain the deformation Contour data, after data processing, the displacement changes of each point on the cutting surface before and after stress release are obtained. Using the stress-strain relationship, the residual stress distribution of the entire section is finally obtained after finite element analysis. This test method can obtain the stress distribution of the entire section, and has no requirements on the shape and material of the test member, and has the characteristics of cost-effectiveness, high efficiency, and simple operation. The use of the transition zone in the method reduces the influence of the boundary effect and improves the test accuracy.

[0067] Before introducing the residual stress testing method of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com