Liquid agent for spraying anion functional fiber material for wall coating and preparation method of liquid agent

A technology of functional fibers and negative ions, applied in the direction of fiber types, fiber treatment, natural fibers, etc., can solve the problems of great harm to the human body, reduction of harmful substance content, single color of wall patterns, etc., to achieve the elimination of toxic and harmful gases and dust, inhibition of purification Air, the effect of improving practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

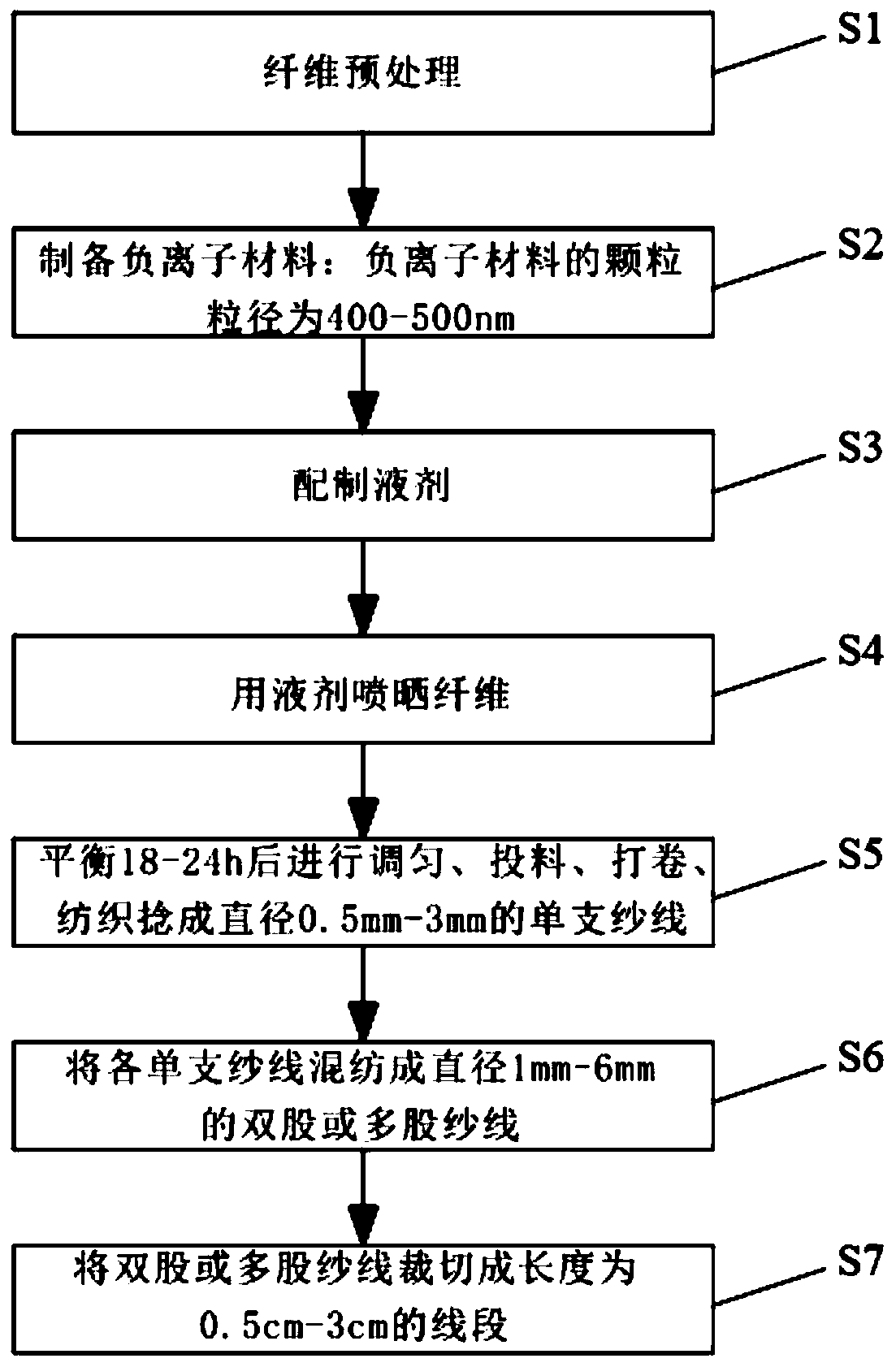

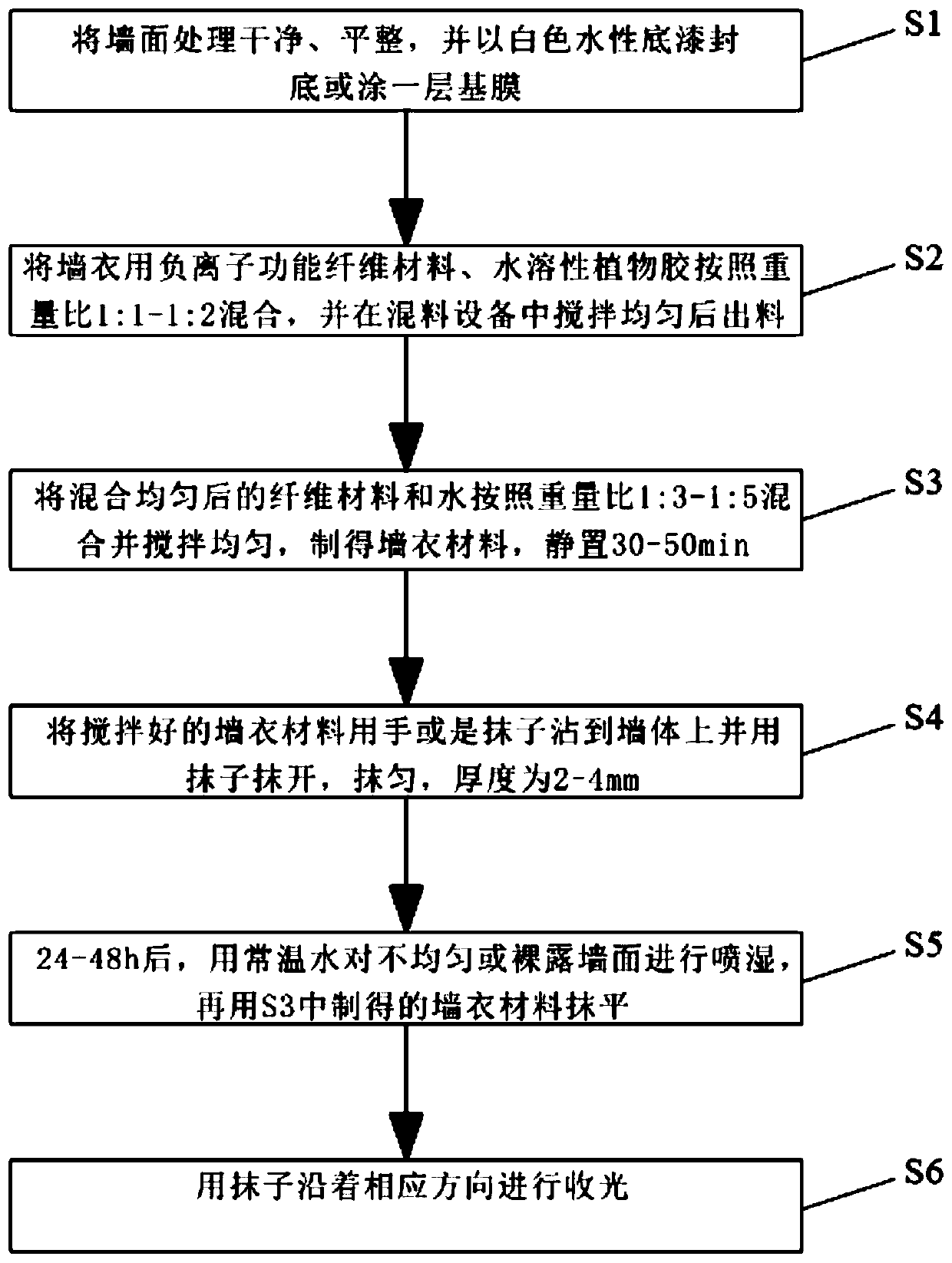

[0039] Anion functional fiber material for wall covering, its preparation method comprises the following steps:

[0040] S1: fiber pretreatment,

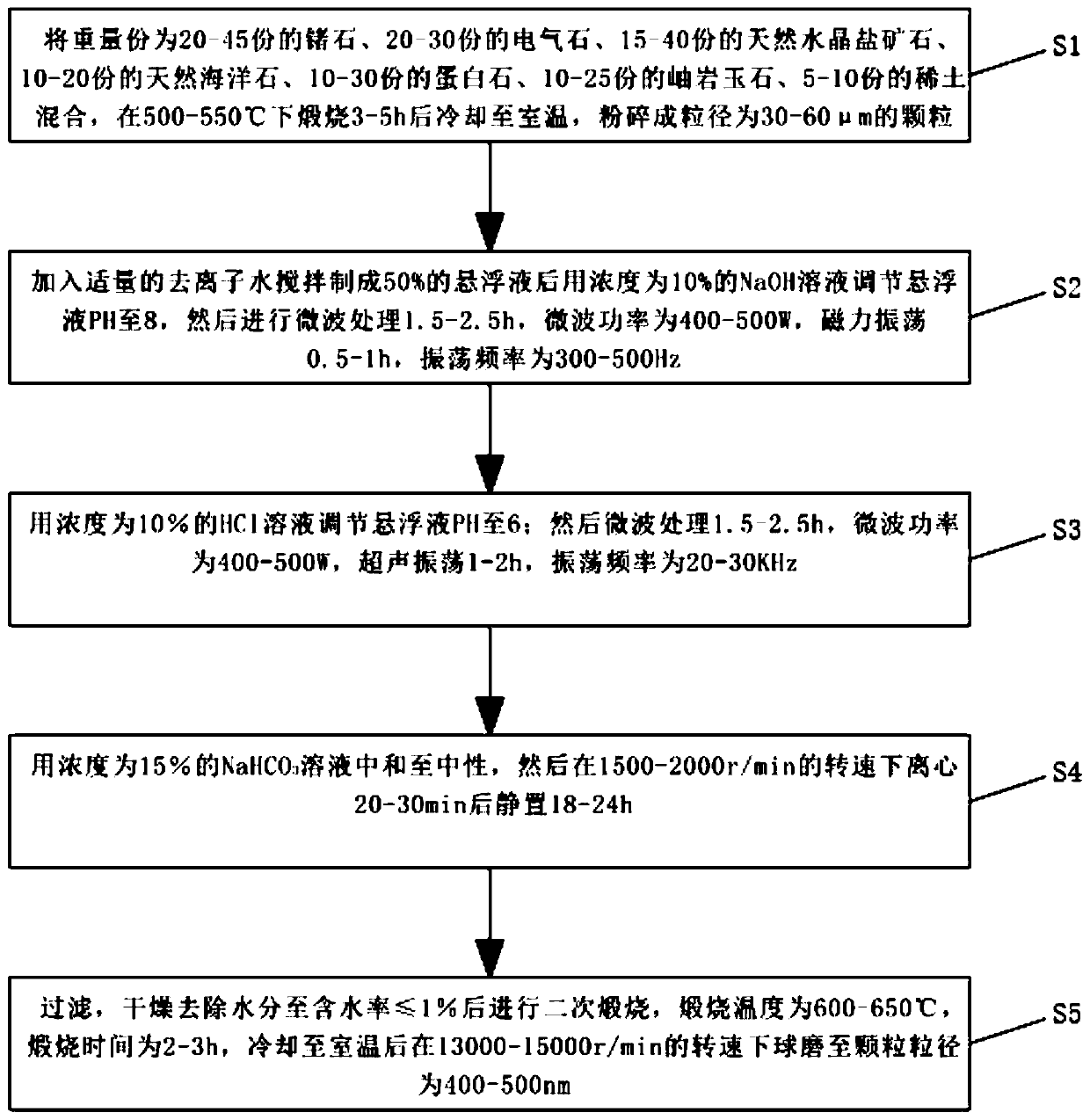

[0041] S2: 20-45 parts by weight of germanite, 20-30 parts of tourmaline, 15-40 parts of seabed placer, 10-20 parts of hornblende, 10-30 parts of opal, 10-25 parts 5-10 parts of pyrophyllite and 5-10 parts of rare earth, calcined at 500-550 ° C for 3-5 hours, cooled to room temperature, and crushed into particles with a particle size of 30-60 μm; adding an appropriate amount of deionized water and stirring to make 50% After the suspension, use a 10% NaOH solution to adjust the pH of the suspension to 8, then carry out microwave treatment for 1.5-2.5h, the microwave power is 400-500W, the magnetic force is oscillated for 0.5-1h, and the oscillation frequency is 300-500Hz; 10% HCl solution to adjust the pH of the suspension to 6; then microwave treatment for 1.5-2.5h, the microwave power is 400-500W, ultrasonic oscillation for 1-2h, ...

specific Embodiment 2

[0058] Anion functional fiber material for wall covering, its preparation method comprises the following steps:

[0059] S01: fiber pretreatment,

[0060] S02: 20-45 parts by weight of germanite, 20-30 parts of tourmaline, 15-40 parts of seabed placer, 10-20 parts of hornblende, 10-30 parts of opal, 10-25 parts 5-10 parts of pyrophyllite and 5-10 parts of rare earth, calcined at 500-550 ° C for 3-5 hours, cooled to room temperature, and crushed into particles with a particle size of 30-60 μm; adding an appropriate amount of deionized water and stirring to make 50% After the suspension, use a 10% NaOH solution to adjust the pH of the suspension to 8, then carry out microwave treatment for 1.5-2.5h, the microwave power is 400-500W, the magnetic force is oscillated for 0.5-1h, and the oscillation frequency is 300-500Hz; 10% HCl solution to adjust the pH of the suspension to 6; then microwave treatment for 1.5-2.5h, the microwave power is 400-500W, ultrasonic oscillation for 1-2h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com