Corrosion-inhibiting zinc powder used for alkaline manganese battery and preparation process for corrosion-inhibiting zinc powder

A technology of alkaline manganese battery and zinc powder, which is applied in the direction of battery electrodes, aqueous electrolyte batteries, metal material coating technology, etc., can solve the problems of low adhesion, waste of rare metals, and limited function of rare metals, and achieve surface quality Improve, slow down self-melting, good battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

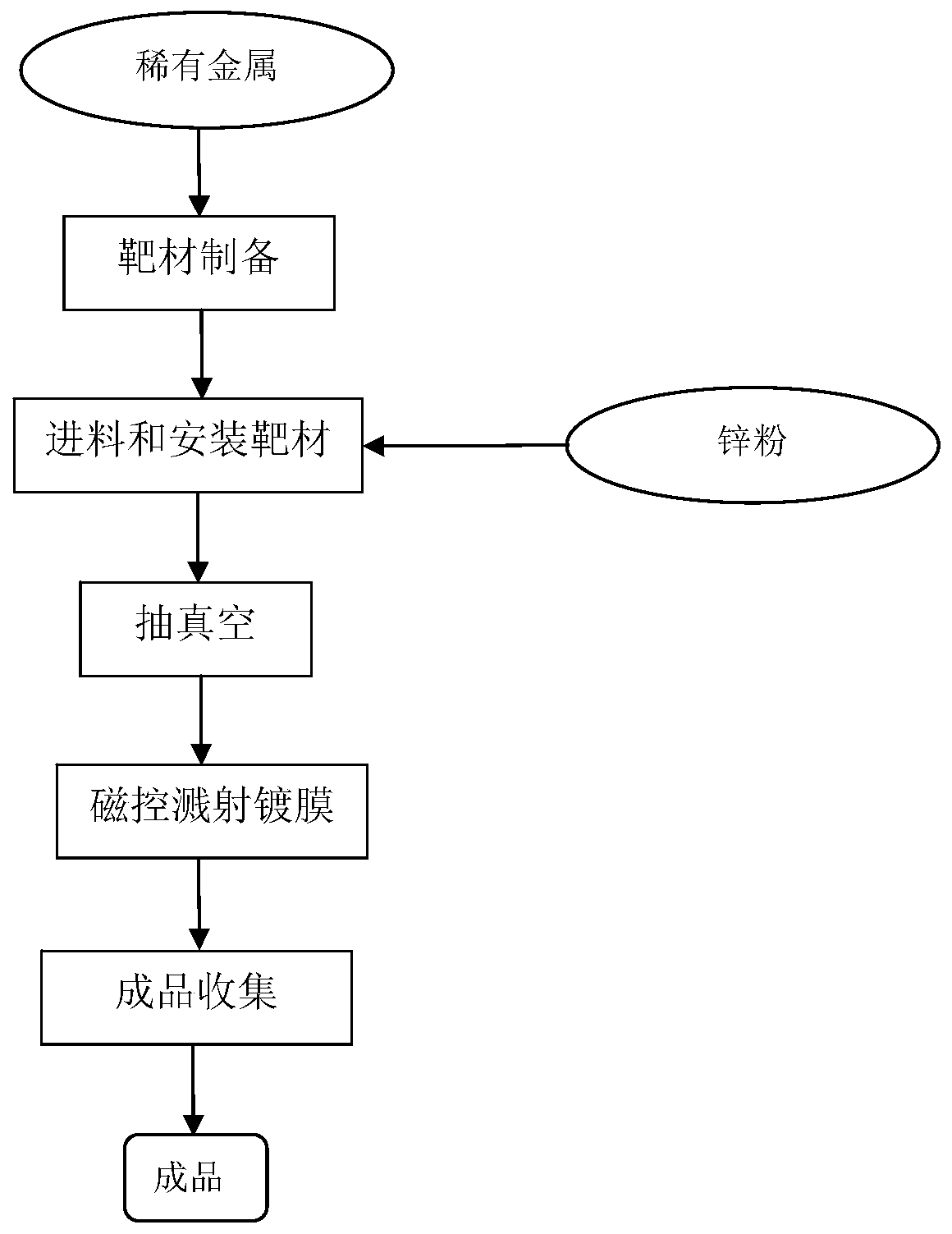

Method used

Image

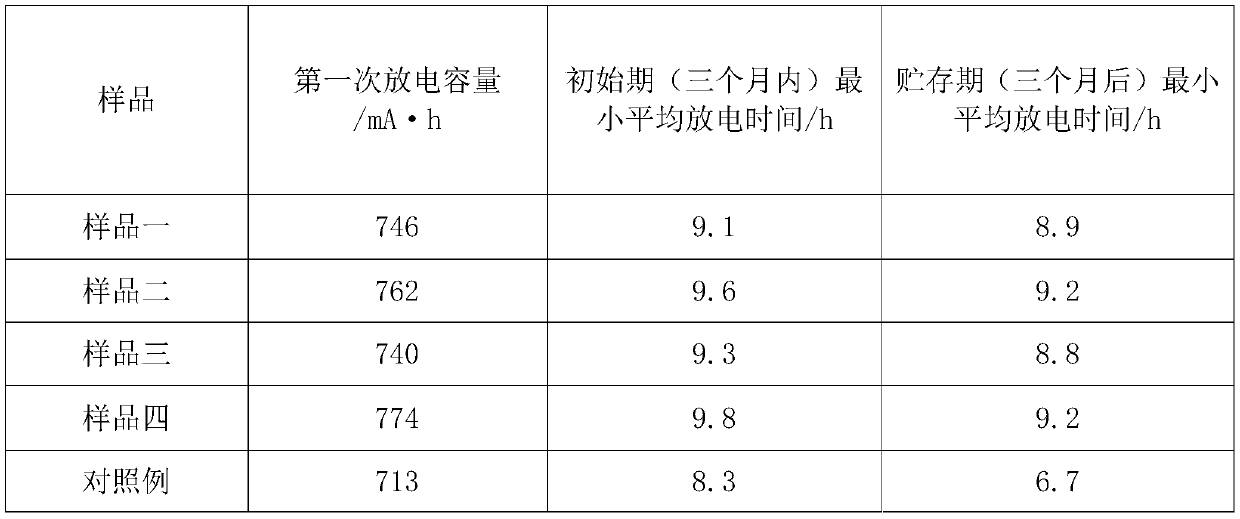

Examples

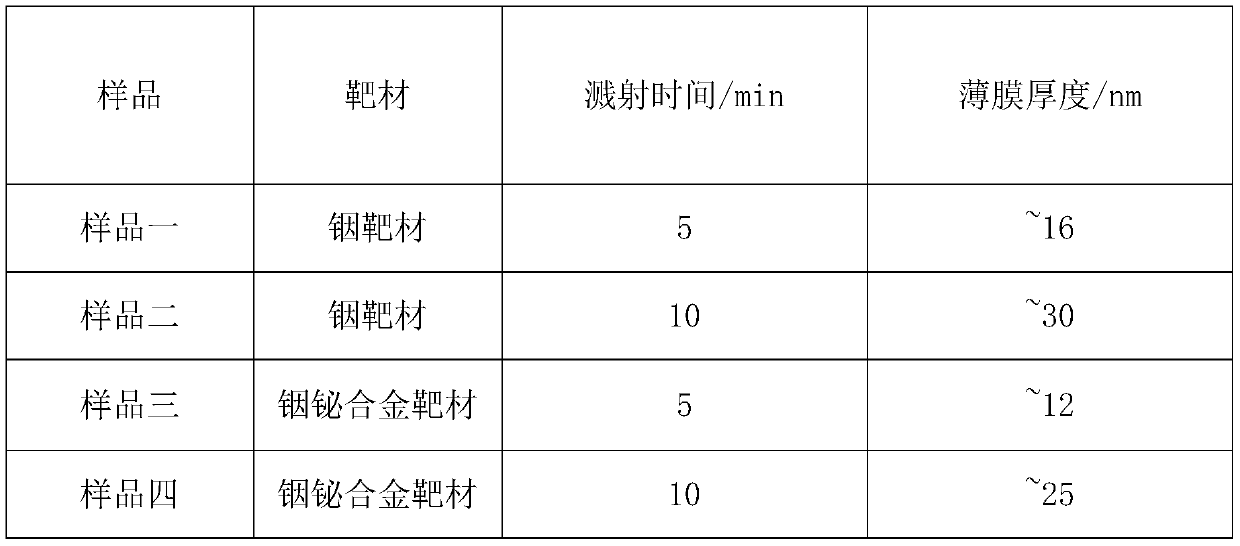

Embodiment 1

[0029] The zinc powder used in this embodiment is commercially available, and the particle size can be between 50 mesh and 400 mesh. The sample particle size used in this embodiment is 100 mesh. The applicant of the present invention has found that the lower the mesh number of the zinc powder particle size, the larger the particle size of the zinc powder particle will affect the performance of the zinc powder. The corrosive rare metal film will further reduce the discharge voltage; the higher the mesh number, the smaller the zinc powder particles can be, and more rare metals need to be plated on the zinc powder particles, so that the zinc powder has corresponding corrosion inhibition, thus Longer magnetron sputtering coating time is required, and more rare metal targets are consumed. From the comprehensive consideration of performance and cost, the particle size of zinc powder is preferably 50 mesh to 400 mesh.

[0030] The target material is self-made, and the target material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com