Immersing precipitation-resistant halogen-free flame-retardant polyamide composite material and preparation method thereof

A flame-retardant polyamide and composite material technology, applied in the field of polyamide composite materials, can solve the problems of increasing the molecular weight of flame retardants and reducing the precipitation rate of flame retardants, so as to improve toughness, reduce the generation of molten droplets, and resist precipitation after immersion in water easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

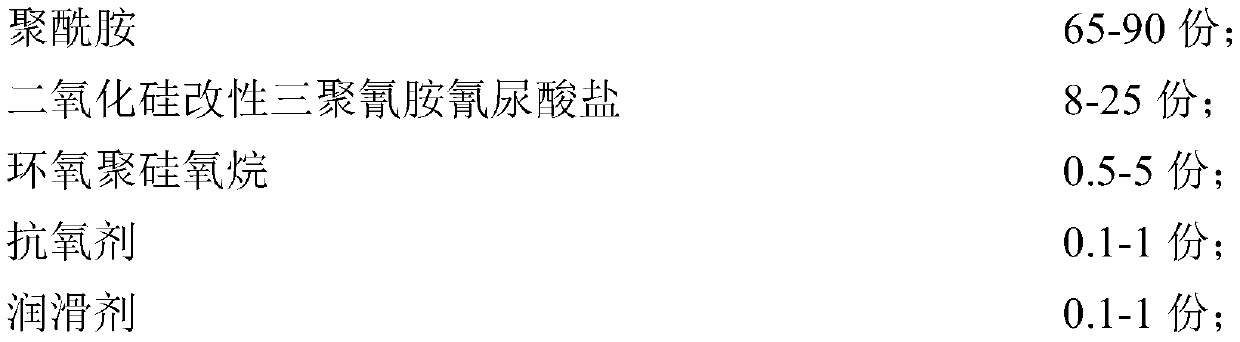

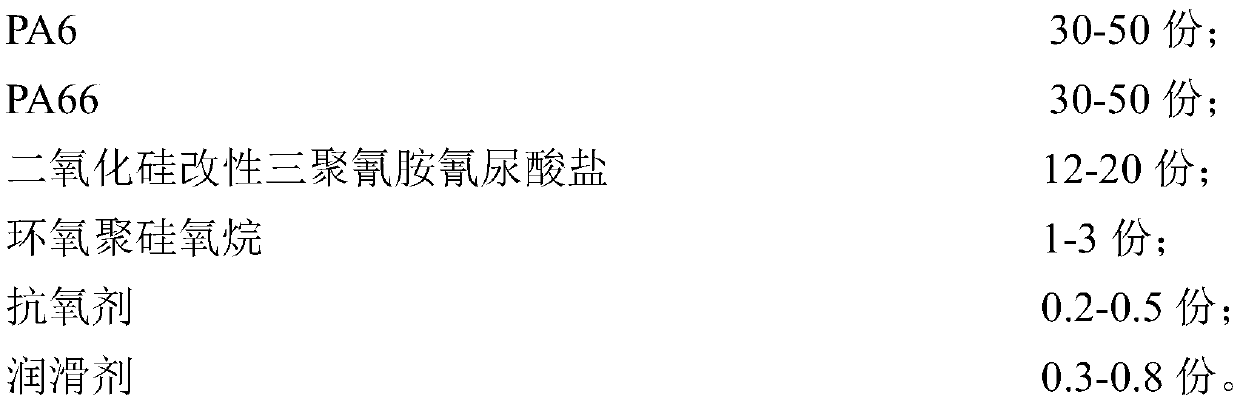

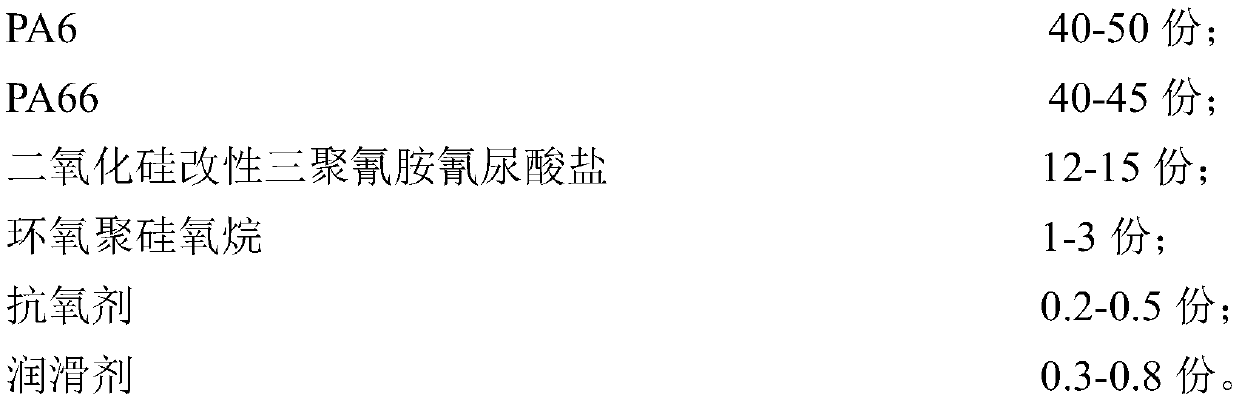

Method used

Image

Examples

Embodiment 1~3 and comparative example 1~2

[0042] The preparation of silicon dioxide modified melamine cyanurate comprises:

[0043] (1) Dissolve 50g of cetyltrimethylammonium bromide in 2000mL of ether and 3000mL of ethanol, add 500g of melamine isocyanate and place in ultrasonic dispersion for 10min. Subsequently, 5000 g of ammonia solution with a pH of 9.5 was added, and mechanically stirred at room temperature 25° C. for 0.5 h to obtain a mixture.

[0044] (2) After adding 250g ethyl orthosilicate to the above mixture, stir for 4h, then slowly add 50g of γ-aminopropyltriethoxysilane and continue to stir for 4h, after filtering, washing with water and washing with ethanol, the white solid obtained is washed at 80 After drying at ℃ for 24 hours, silica-modified melamine cyanurate was obtained.

[0045] Silica Modified Melamine Cyanurate

[0046] The polyamide 66, polyamide 6, silica-modified melamine cyanurate, epoxy polysiloxane, antioxidant 1098, and lubricant TAF are fed from the main feeding port of the twin-sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com