A kind of craft and device of ferric phosphate synthesis

A ferric phosphate and process technology, which is applied in the field of ferric phosphate synthesis process and equipment, can solve the problems of single oxidant pH value regulator and low degree of automation, and achieve the effects of wide selection range, high automation, and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

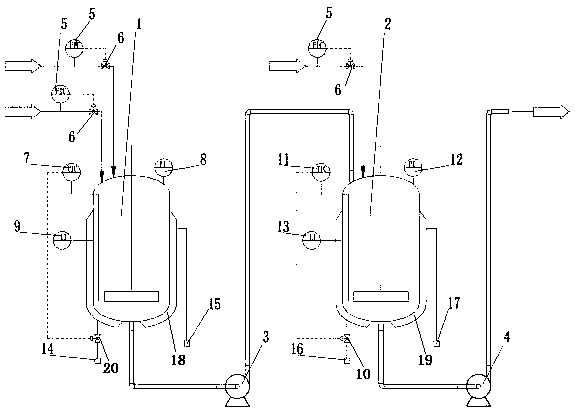

[0030] Adopt above-mentioned device to synthesize ferric phosphate, process is as follows:

[0031] Oxidation reaction: select iron solution with iron ion concentration of 1.2mol / L, phosphate radical concentration of 1.22mol / L, and sulfate radical concentration of 1.2mol / L (most of the ferrous ions in the iron raw materials are oxidized to trivalent iron ions in the natural state , there is only a small amount of ferrous ions, and the total concentration of ferrous ions and ferric ions here is 1.2mol / L), and 11000kg of iron solution is transported by the iron solution feeder and passed through the flow detector 5 and the third solenoid valve 6 Quantitatively enter the oxidation kettle 1, start the stirring at the same time, transport by the oxidant feeder and quantitatively add 964kg hydrogen peroxide into the oxidation kettle 1 through the flow detector 5 and the third electromagnetic valve 6, the hydrogen peroxide feed time is 60 minutes, and pass through the oxidation kettle...

Embodiment 2

[0036] Adopt above-mentioned device to synthesize ferric phosphate, process is as follows:

[0037] Oxidation reaction: select an iron solution with an iron ion concentration of 1.3mol / L (here, the total concentration of ferrous ions and ferric ions is 1.3mol / L), a phosphate concentration of 1.32mol / L, and a sulfate concentration of 1.3mol / L , 8800kg of iron solution is transported by the iron solution feeder and quantitatively enters the oxidation kettle 1 through the flow detector 5 and the third electromagnetic valve 6, and at the same time, the stirring is started, and it is delivered by the oxidant feeder and passed through the flow detector 5 and the third solenoid valve. Solenoid valve 6 quantitatively and slowly adds 900 kg of hydrogen peroxide into the oxidation kettle 1, the hydrogen peroxide feeding time is 60 minutes, and the oxidation temperature in the oxidation kettle 1 is controlled by passing fluid into the first heat exchange interlayer 18 outside the oxidatio...

Embodiment 3

[0041] Adopt above-mentioned device to synthesize ferric phosphate, process is as follows:

[0042] Oxidation reaction: select iron solution with iron ion concentration of 1mol / L (here, the total concentration of ferrous ion and ferric ion is 1mol / L), phosphate concentration of 0.52mol / L, sulfate concentration of 1mol / L, and 5500kg The iron solution is delivered by the iron solution feeder and quantitatively enters the oxidation kettle 1 through the flow detector 5 and the third electromagnetic valve 6, and at the same time, the stirring is started, and it is delivered by the oxidant feeder and passes through the flow detector 5 and the third electromagnetic valve 6 Slowly add 433 kg of hydrogen peroxide quantitatively into the oxidation kettle 1, the hydrogen peroxide feeding time is 30 minutes, and control the oxidation temperature in the oxidation kettle 1 by passing hot fluid into the first heat exchange interlayer 18 outside the oxidation kettle 1 to ≤70°C (here the oxidat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com