Novel composite ceramic with high thermal shock resistance and processing process thereof

A composite ceramic and processing technology technology, which is applied in the field of composite ceramics to achieve the effects of being beneficial to sintering and densification, increasing channels and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

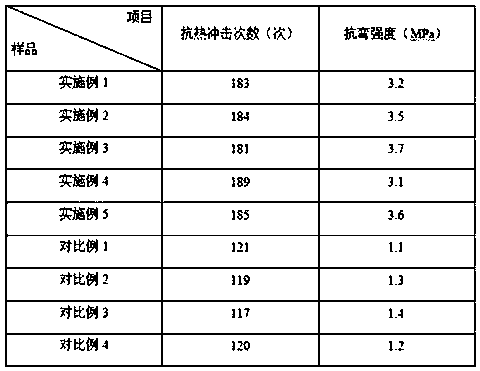

Examples

Embodiment 1

[0041] A new composite ceramic with high thermal shock resistance, the composite ceramic includes the following components in parts by weight: 20 parts of magnesium powder, 5 parts of silicon powder, 5 parts of carbon powder, 60 parts of feldspar and mercapto compound trimethylol Propane tris(3-mercaptopropionate) 3 parts.

[0042] A new type of composite ceramic with high thermal shock resistance is processed by using the above-mentioned raw materials. The processing technology of the composite ceramic includes the following steps:

[0043] (1) Weigh 20 parts of magnesium powder and 60 parts of feldspar into a ball milling jar, use absolute ethanol as the ball milling medium, vacuumize the ball milling jar and fill it with argon, ball mill for 18 hours, and then put it in an oven at 60°C Dry for 1 hour to obtain the first mixture;

[0044] (2) Put the first mixed material into a hot-press sintering furnace, and perform pre-sintering treatment in a nitrogen atmosphere to obta...

Embodiment 2

[0049] A new composite ceramic with high thermal shock resistance, the composite ceramic includes the following components in parts by weight: 25 parts of magnesium powder, 6 parts of silicon powder, 6 parts of carbon powder, 65 parts of mica and pentaerythritol tetrakis (3-mercaptopropane acid ester) 4 parts.

[0050] A new type of composite ceramic with high thermal shock resistance is processed by using the above-mentioned raw materials. The processing technology of the composite ceramic includes the following steps:

[0051] (1) Weigh 25 parts of magnesium powder and 65 parts of mica and put them into a ball milling jar, use absolute ethanol as the ball milling medium, vacuumize the ball milling jar and fill it with argon, ball mill for 19 hours, and then bake in an oven at 65°C Dry for 1.5h to obtain the first mixture;

[0052] (2) Put the first mixture into the hot-press sintering furnace, and perform pre-sintering treatment in nitrogen atmosphere to obtain pre-sinterin...

Embodiment 3

[0057] A new type of composite ceramic with high thermal shock resistance, the composite ceramic includes the following components in parts by weight: 30 parts of magnesium powder, 7 parts of silicon powder, 7 parts of carbon powder, 70 parts of kaolin and 5 parts of polymethyl methacrylate share.

[0058] A new type of composite ceramic with high thermal shock resistance is processed by using the above-mentioned raw materials. The processing technology of the composite ceramic includes the following steps:

[0059] (1) Weigh 30 parts of magnesium powder and 70 parts of kaolin into a ball milling jar, use absolute ethanol as the ball milling medium, vacuumize the ball milling jar and fill it with argon, ball mill for 21 hours, and then bake in an oven at 70°C Dry for 2 hours to obtain the first mixture;

[0060] (2) Put the first mixed material into the hot-press sintering furnace, and perform pre-sintering treatment in nitrogen atmosphere to obtain pre-sintering material. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com