Nifedipine solid dispersion and preparation method thereof

A technology of dipine solid and nifedipine, which is applied in the directions of non-active ingredient medical preparations, active ingredients-containing medical preparations, pharmaceutical formulas, etc., can solve the problems of low oral bioavailability, decreased solubility, slow drug release, etc. , to achieve the effect of improving bioavailability, bioavailability, and dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation of embodiment 1 nifedipine solid dispersion

[0043] 1, the preparation method of nifedipine solid dispersion, comprises the following steps:

[0044] S1. Weigh 300g of nifedipine and 700g of povidone PVP-VA64700g after passing through a 100-mesh sieve in the dark, and dry at 60°C for 6h;

[0045] S2. Mechanically mixing nifedipine and povidone PVP-VA64 in a closed container for 15 minutes to obtain a physical mixture;

[0046] S3. On the differential-speed asymmetric twin-screw extruder with the preset temperature of each section from the first to the sixth zone of the barrel at 150°C, 160°C, 165°C, 175°C, 175°C, and 165°C, single and double The head screw speed is 120 / 60r / min for extrusion, the extrudate is cooled and pulverized, and passed through an 80-mesh sieve to obtain the nifedipine solid dispersion.

[0047] 2. Results

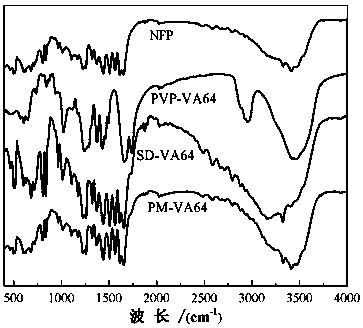

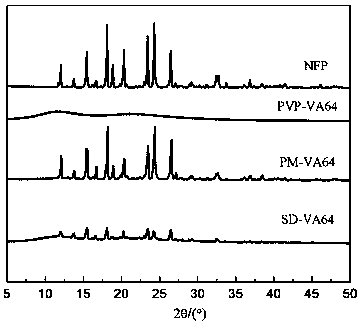

[0048] figure 1 and figure 2 Infrared spectrum and XRD spectrum of nifedipine (NEP), carrier povidone (PVP-VA64), physi...

Embodiment 2

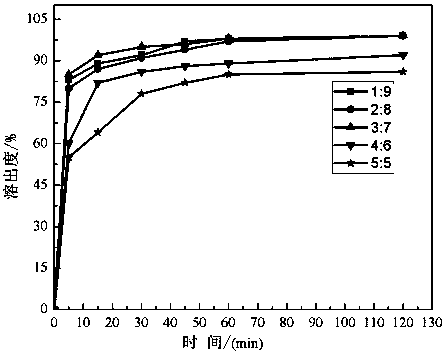

[0051] Embodiment 2 prepares nifedipine solid dispersion in different proportions

[0052] 1. Preparation method

[0053] Take by weighing respectively the nifedipine and PVP-VA64 of corresponding quality according to the ratio of table 1, then with reference to the preparation method of embodiment 1, nifedipine and PVP-VA64 are carried out mechanical mixing 15min in airtight container, obtain physical mixture; The pre-set temperature of each section from the first to the sixth zone of the barrel is 150°C, 160°C, 165°C, 175°C, 175°C, 165°C on the differential speed asymmetrical twin-screw extruder. Extrude at 120 / 60r / min, cool and pulverize the extrudate, and pass through an 80-mesh sieve to obtain nifedipine solid dispersions prepared with raw materials in different proportions.

[0054] The mass fraction of table 1 nifedipine and PVP-VA64

[0055] name

1

2

3

4

5

Nifedipine (g)

100

200

300

400

500

PVP-VA64(g)

900

8...

Embodiment 3

[0058] Embodiment 3 prepares nifedipine solid dispersion with common twin-screw extruder

[0059] 1, except that the differential speed asymmetric twin-screw extruder is replaced by a common twin-screw extruder, with reference to the method of embodiment 1, the preparation of nifedipine solid dispersion comprises the following steps:

[0060] S1. Weigh 300g of nifedipine and 700g of povidone PVP-VA64700g after passing through a 100-mesh sieve in the dark, and dry at 60°C for 6h;

[0061] S2. Mechanically mixing nifedipine and povidone PVP-VA64 in a closed container for 15 minutes to obtain a physical mixture;

[0062] S3. On an ordinary twin-screw extruder with preset temperatures of 150°C, 160°C, 165°C, 175°C, 175°C, and 165°C in each section of the barrel from zone 1 to zone 6, the screw speed is 120r / min extrusion, the extrudate was cooled and pulverized, and passed through an 80-mesh sieve to obtain a solid dispersion of nifedipine (SD-common).

[0063] 2. Results

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com