A high temperature superconducting motor

A high-temperature superconducting and superconducting magnet technology, applied in electromechanical devices, electrical components, electric components, etc., can solve the problems of low support of all-composite materials, increase the difficulty of manufacturing, and large circumferential displacement of the coil, and improve the rigidity of the rotor. and operational stability, reducing manufacturing difficulty and material cost, and increasing power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

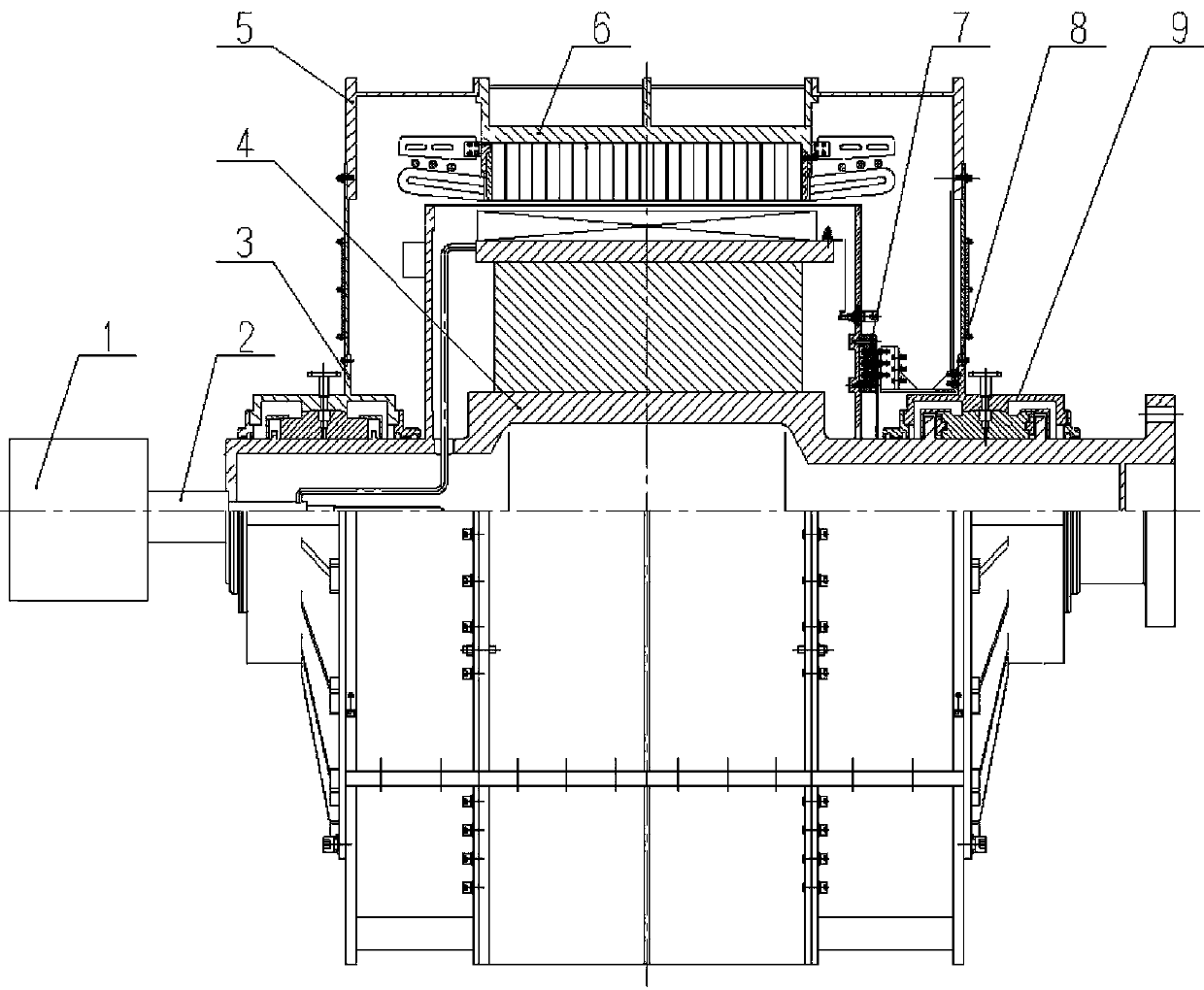

[0024] Such as Figure 1 to Figure 5 Shown is a basic embodiment of the invention.

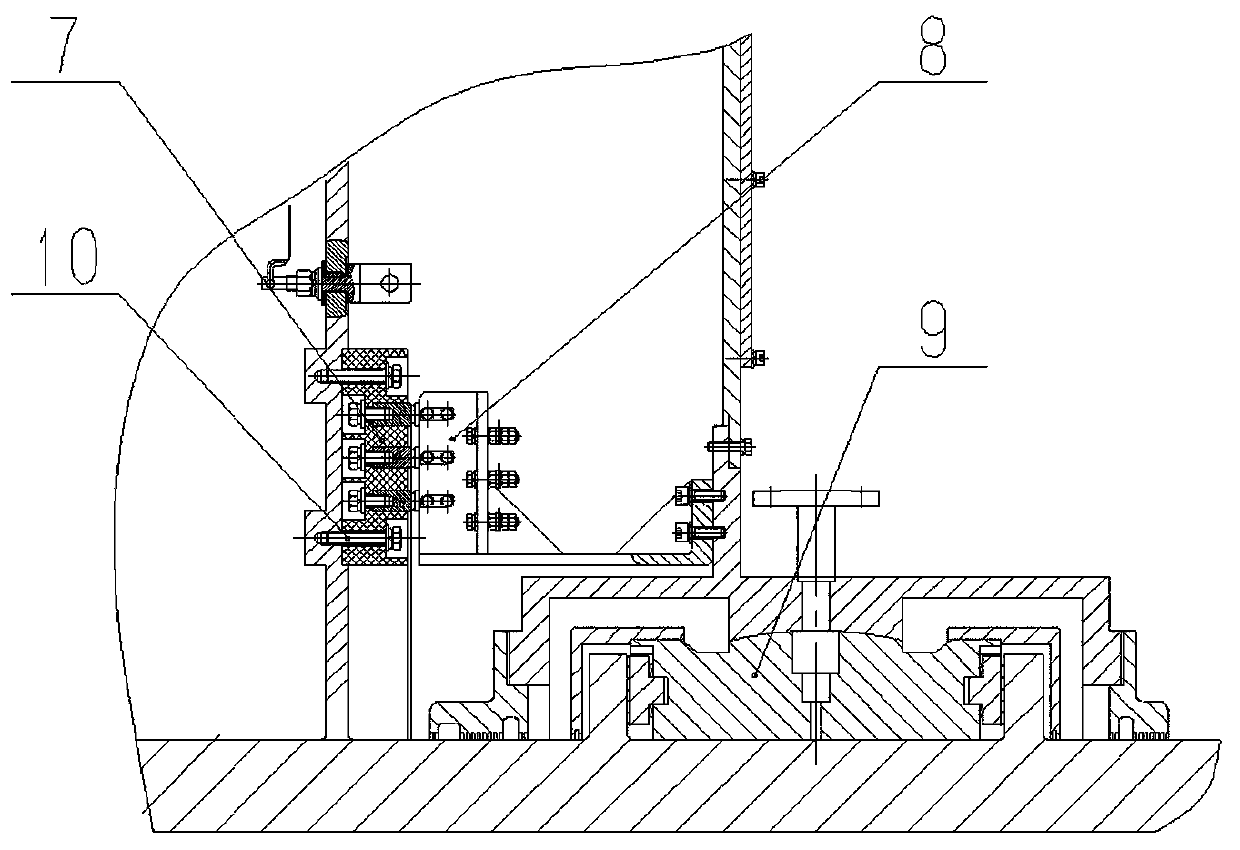

[0025] A high-temperature superconducting motor, comprising a low-temperature refrigeration system 1, a refrigerant transmission coupling device 2, a non-drive end bearing housing 3 and bearings, a rotor 4, an end cover 5, a stator 6, a disc collector ring 7, and a brush holder with electric brushes 8. The driving end bearing seat 9 and the bearing etc. are composed.

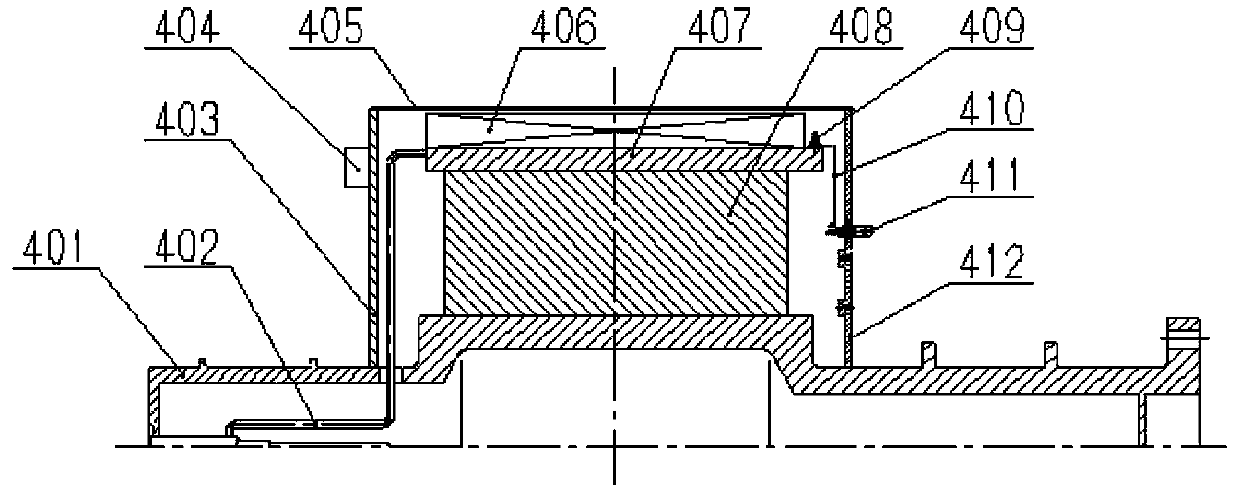

[0026] The stator 6 adopts an air-gap armature structure without iron teeth, and is composed of a machine base, an iron core punch 61, a wedge key 62, a coil fixing part 63, a stator coil 64 and a slot wedge 65, and the coil fixing part 63 is an embedded The glass fiber composite material block 622 of the stainless steel metal plate 621, the stator coil 64 can adopt a single-layer transposition coil structure, the coil fixing part 63 is placed in the dovetail slot of the iron core punch 61, and is fixed by wedge-shaped key 62 e...

Embodiment 2

[0030] The difference from Embodiment 1 is that the coil fixing member 63 is a glass fiber composite material block 622 embedded with a high-strength aluminum alloy plate.

Embodiment 3

[0032] The difference from Embodiment 1 is that the stator armature winding adopts a double-layer transposition coil structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com