Blue phase liquid crystal film, and preparation method and application thereof

A blue-phase liquid crystal and application technology, applied in the field of blue-phase liquid crystal film and its preparation, can solve the problems of narrow blue phase temperature range, low Q value and high threshold value, and reduce the unevenness of lattice size distribution and the stability of wavelength. Improve the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0035] The first embodiment of the present invention provides a blue phase liquid crystal film, the components of which include: 30wt% liquid crystal monomer C6M participating in polymerization, 59.5wt% liquid crystal molecule HTG135200-100 not participating in polymerization, 2.9-3.7wt % chiral dopant, 5wt% cross-linking agent, 0.2-2wt% photoinitiator and 0.5-2wt% small molecule dye.

[0036] Preferably, the thickness of the blue phase liquid crystal film is 10-500 μm. When the thickness of the blue-phase liquid crystal film is less than 10 μm, the period number of the periodic structure in the blue-phase liquid crystal film will be less, which is not enough to provide high enough reflectivity and band edge density, and is not enough to make the high threshold band edge reach Threshold to emit dual-wavelength laser; when the thickness of the blue-phase liquid crystal film is higher than 500 μm, the temperature of the upper surface and the lower surface is difficult to be unif...

no. 2 approach

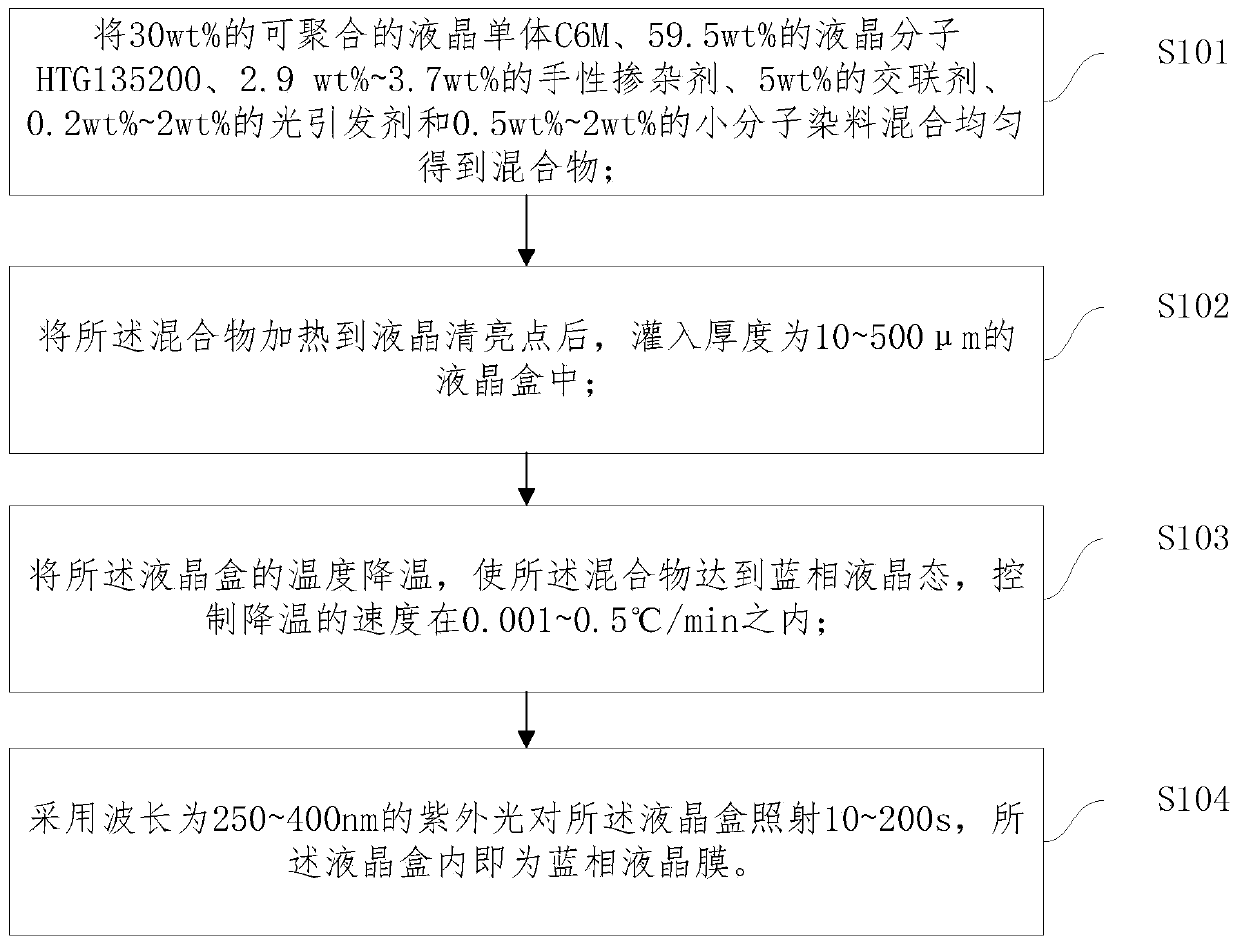

[0045] figure 1 It is a flowchart of a preparation method of a blue phase liquid crystal film provided in the second embodiment of the present invention.

[0046] like figure 1 As shown, the method includes step S101 to step S104.

[0047] In step S101, 30wt% of polymerizable liquid crystal monomer C6M, 59.5wt% of liquid crystal molecules HTG135200-100 that do not participate in polymerization, 2.9-3.7wt% of chiral dopant, 5wt% of cross-linking agent, 0.2- 2wt% photoinitiator and 0.5-2wt% small molecule dye are put into a container and mixed uniformly to obtain a mixture.

[0048] Step S102, after heating the mixture to the liquid crystal clearing point, pouring it into a liquid crystal cell with a thickness of 10-500 μm.

[0049] Wherein, the liquid crystal clearing point temperature of most liquid crystals in the present invention is generally above 80°C.

[0050] In step S103, the temperature of the liquid crystal cell is lowered to make the mixture reach a blue phase l...

Embodiment 1

[0062] After mixing 59.5wt% of liquid crystal molecule HTG135200-100 and 30wt% of polymerizable liquid crystal monomer C6M, 0.5wt% of photoinitiator I-651, 5wt% of TMPTA, 3.3wt% of R5011 and 0.5 Wt% small molecular dyes are put into a container and mixed evenly to obtain a liquid crystal mixture. Among them, coumarin 6 is selected as the small molecular dye.

[0063] The above-mentioned liquid crystal mixture is heated to its liquid crystal clearing point or above its liquid crystal clearing point, heated to 90° C. in Example 1, and poured into a liquid crystal cell with a thickness of 50 μm between the liquid crystal cells.

[0064] Cool the liquid crystal cell to the blue phase liquid crystal state (BPI state), and control the cooling speed at 0.5°C / min

[0065] Irradiate with ultraviolet light with a wavelength of 385nm for 80s.

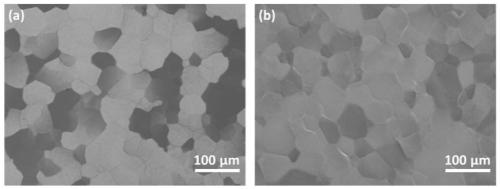

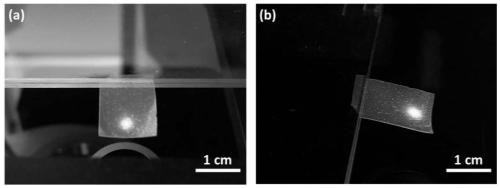

[0066] The liquid crystal cell is disassembled, and the blue-phase liquid crystal polymer film is taken out to obtain a blue-phase liquid cryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com