Stepless speed regulating energy-saving hydraulic system for cleaning sweeper truck

A technology of stepless speed regulation and hydraulic system, applied in the direction of road cleaning, cleaning methods, fluid pressure actuating devices, etc., can solve the problems of system temperature rise, high overflow pressure, system energy consumption, etc., to achieve outstanding substantive features, Convenient for overvoltage protection and low energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The features of the present invention and other relevant features are described in further detail below through the embodiments, so as to facilitate the understanding of those skilled in the art:

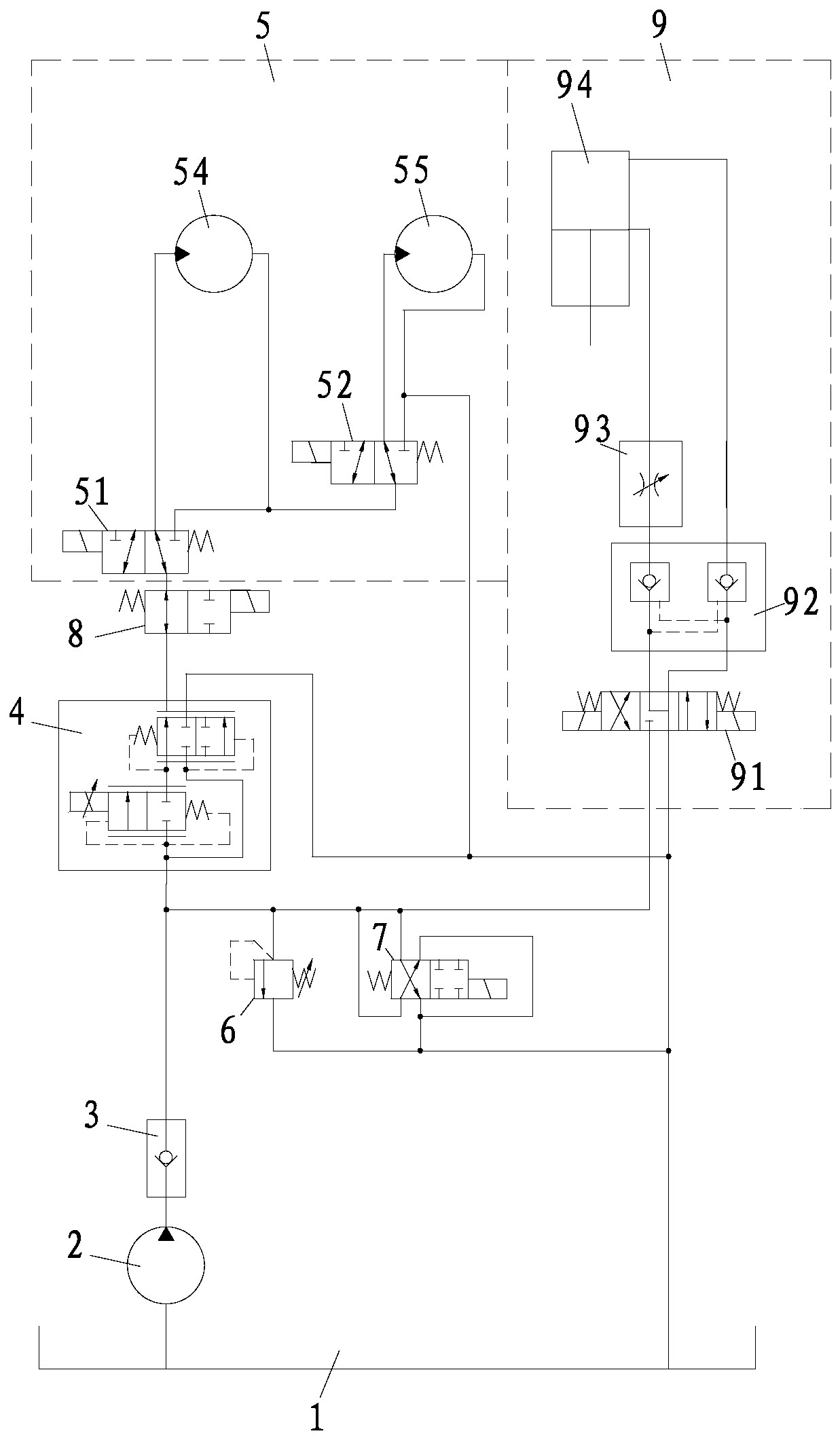

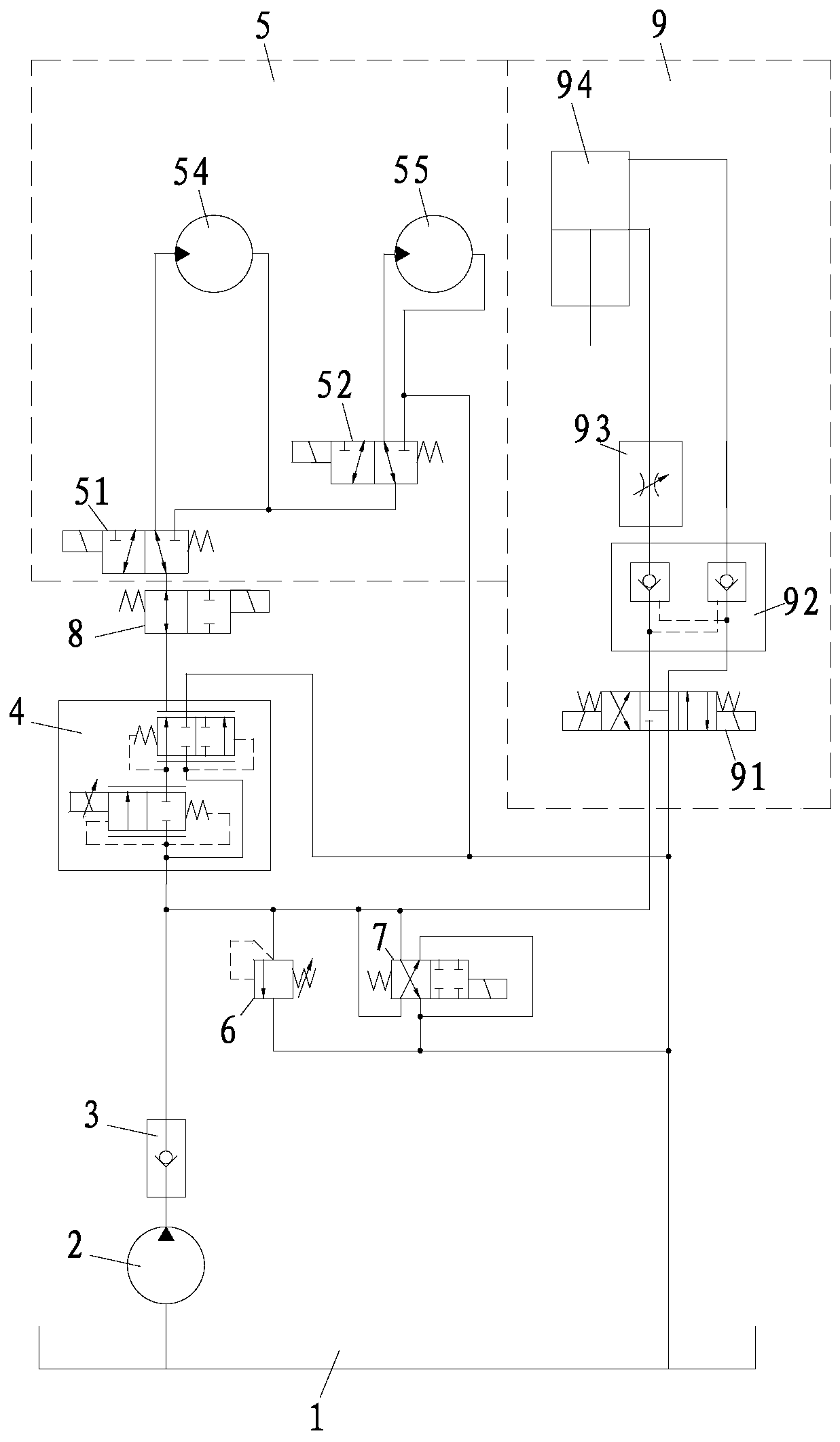

[0018] Such as figure 1 As shown, a stepless speed regulation energy-saving hydraulic system of a washing and sweeping vehicle includes a hydraulic oil tank 1, an oil pump 2, a one-way valve 3, a proportional flow control valve 4, and a hydraulic motor unit 5 for driving the sweeping plate of the washing and sweeping vehicle to rotate , an overflow valve 6, an unloading valve 7, an on-off control solenoid valve 8, and a hydraulic cylinder unit 9 for driving the sweeping swing, the proportional flow control valve 4 is provided with an oil inlet, a flow control oil outlet, And the bypass oil drain port, wherein, the hydraulic oil tank 1, the oil pump 2, the one-way valve 3, the oil inlet port and the flow control oil outlet port of the proportional flow control valve 4, the on-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com