Nanocrystalline magnetic core magnetic field heat treatment method suitable for A type leakage protector

A heat treatment method and nanocrystalline technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve problems such as reduced residual current detection sensitivity, personal electric shock or electrical fire accidents, reduced magnetic field strength and induced potential, etc., to reduce personal injury Electric shock or electrical fire accidents, reliable tripping, and the effect of improving detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

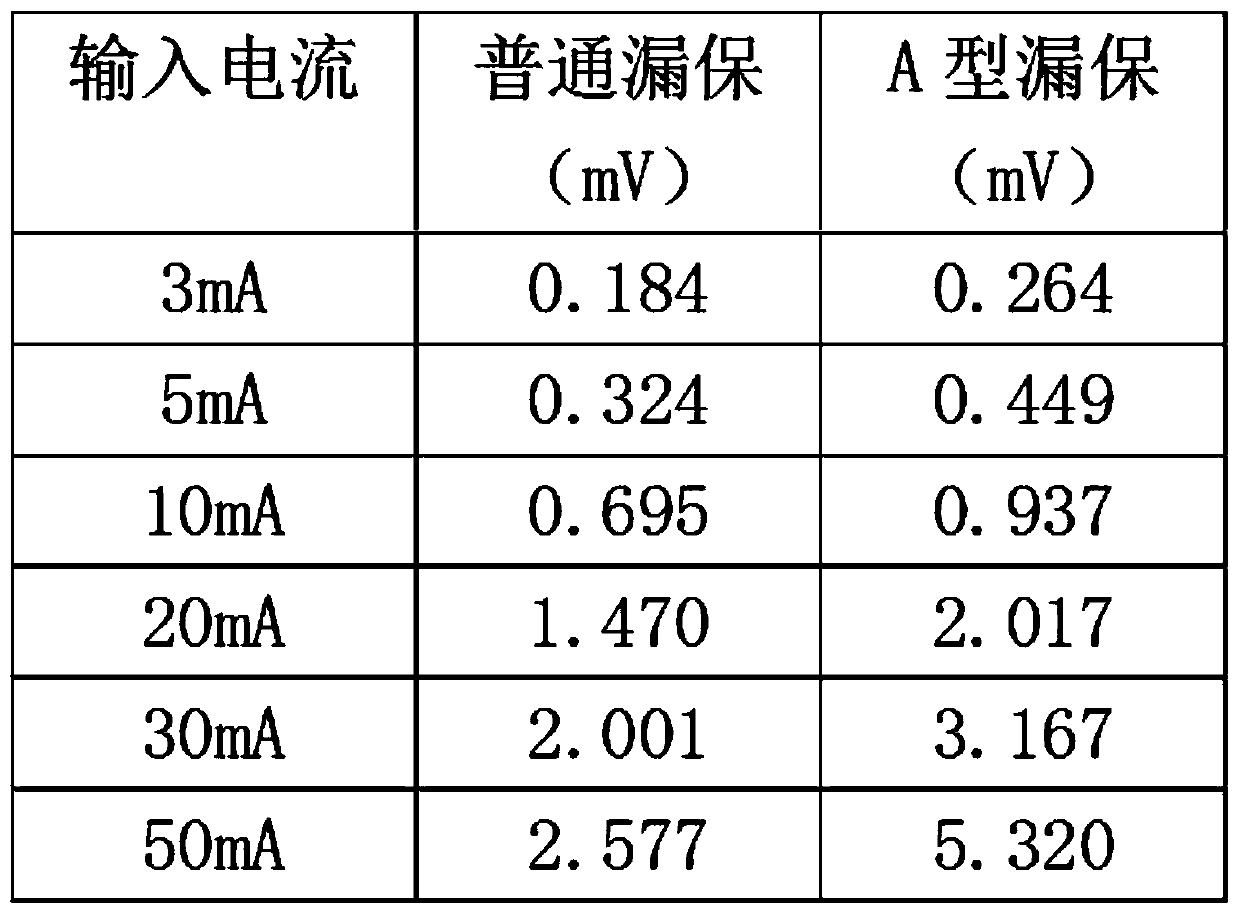

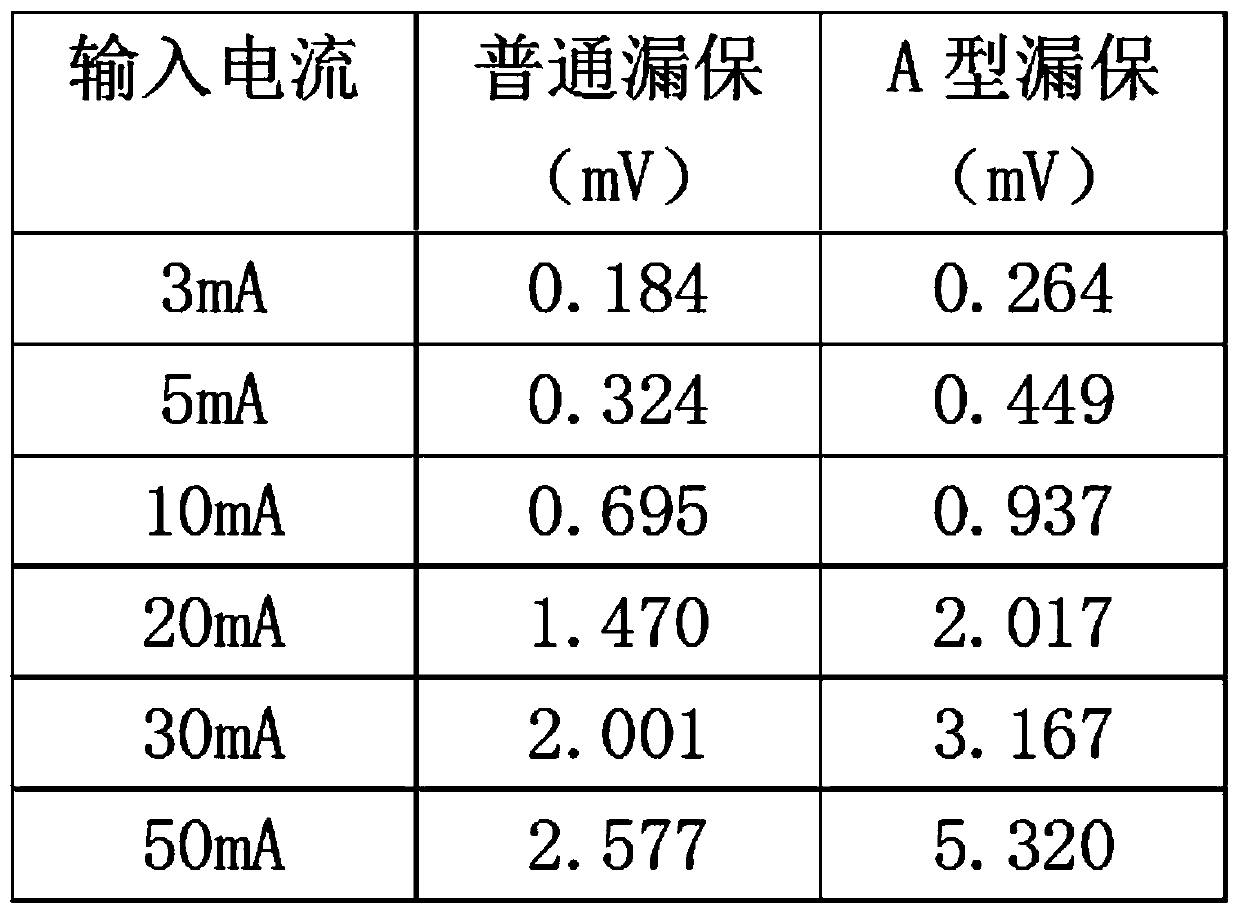

[0015] Refer to figure 1 A magnetic field heat treatment method for nanocrystalline magnetic cores suitable for type A leakage protection is shown, including the following steps: (1) Place the nanocrystalline magnetic core to be processed in a transverse magnetic furnace and pass protective gas; (2) Carry out heat treatment and magnetic treatment, including: the first stage: the temperature rises from room temperature to about 560℃, heating and holding for about 90 minutes; the second stage: the first stage heat-treated nanocrystalline core is cooled to room temperature; the third stage : Place the nanocrystalline magnetic core cooled in the second stage in a transverse magnetic furnace and pass protective gas. The temperature will rise from room temperature to about 420℃, heating and holding for about 60 minutes, and the transverse magnetic treatment will be carried out while annealing , The fourth stage: out of the furnace, the nanocrystalline magnetic core after the third st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com