Composite ink, preparation method thereof, and device

A technology of ink and nano-metal particles, which is applied in the manufacture of electric solid-state devices, semiconductor devices, and semiconductor/solid-state devices, etc., can solve the problems of light quenching and damage of luminescent materials, and physical or chemical changes in other structures of devices, so as to improve luminescence. Efficiency, the effect of improving compound efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

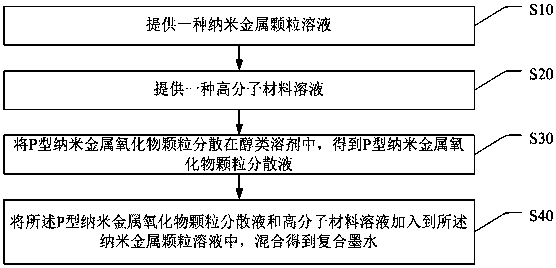

[0030] see figure 1 , figure 1 It is a flowchart of a preferred embodiment of a method for preparing a composite ink of the present invention, as shown in the figure, which includes steps:

[0031] S10, providing a nano metal particle solution;

[0032] S20, providing a polymer material solution;

[0033] S30, dispersing the P-type nano metal oxide particles in an alcohol solvent to obtain a P-type nano metal oxide particle dispersion;

[0034] S40, adding the P-type nano metal oxide particle dispersion and polymer material solution into the nano metal particle solution, and mixing to obtain a composite ink.

[0035] Specifically, inkjet printing technology, as an effective way for the industrialization and large-scale production of existing thin-film display devices, can significantly increase the production capacity of thin-film display devices and reduce their production costs. However, because the inkjet printing equipment requires high physical and chemical properties...

Embodiment 1

[0060] A preparation method of composite ink containing PEDOT / PSS:

[0061] Configure four volumes each of 2ml, the solvent is isopropanol, and the concentration is respectively 15mg / ml, 12mg / ml, 10mg / ml, and 8mg / ml of nano-silver spherical particle solution;

[0062] The volume is 200ml, the solvent is ethanol, and the concentration is 30mg / ml nano-titanium oxide particle solution, vigorously stirred to make it evenly dispersed, and then divided into four equal parts;

[0063] Add concentration dropwise respectively in above-mentioned four parts of nano-titanium oxide particle solutions and be 15mg / ml, 12mg / ml, 10mg / ml, the nano-silver spherical particle solution of 8mg / ml, and continue stirring at room temperature for 24 hours, obtain four A nano-silver spherical particle-nano-titanium oxide composite ink.

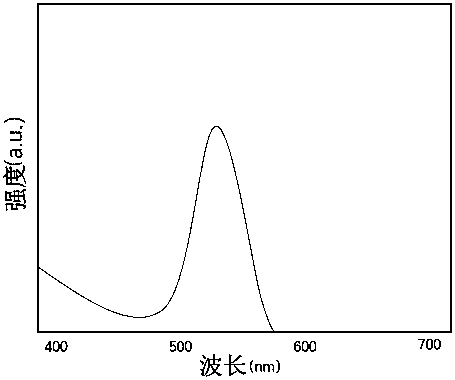

[0064] Among them, the composite ink added with 15mg / ml nano-silver spherical particle solution was deposited into a film, and its ultraviolet-visible spectrum was tested...

Embodiment 2

[0071] A kind of composite ink preparation method containing PMMA:

[0072] Configure four volumes each of 5ml, the solvent is ethylene glycol, and the concentrations are respectively 18mg / ml, 6 mg / ml, 3 mg / ml, and 1 mg / ml of nano-silver spherical particle solutions;

[0073] The volume is 200ml, the solvent is decanyl alcohol, and the concentration is 70mg / ml of nano-molybdenum oxide particle solution, stir vigorously to make it evenly dispersed, and then divide it into four equal parts;

[0074] To the above-mentioned four parts of nano-molybdenum oxide particle solutions, add dropwise the nano-silver spherical particle solutions with a concentration of 18 mg / ml, 6 mg / ml, 3 mg / ml, and 1 mg / ml, and continue stirring at room temperature for 24 hours, that is, Four parts of nano-silver spherical particles-nano-molybdenum oxide composite ink were obtained.

[0075] Among them, the composite ink added with 18mg / ml nano-silver spherical particle solution was deposited into a film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com