Enhancement type silencer

A muffler and enhanced technology, applied in the direction of mufflers, machines/engines, engine components, etc., can solve the problems of engine exhaust gas flow not smooth, increase engine power loss, unfavorable engine efficiency, etc., achieve good muffler effect, reduce Effects of Power Loss, Resonance Efficiency and Strength Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

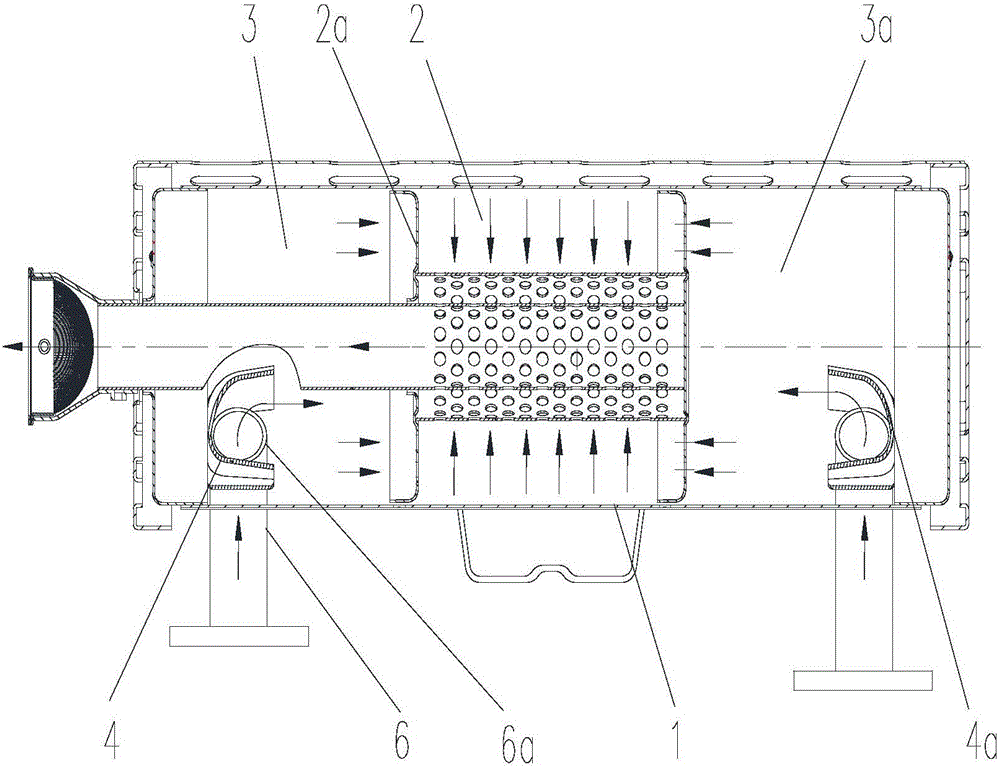

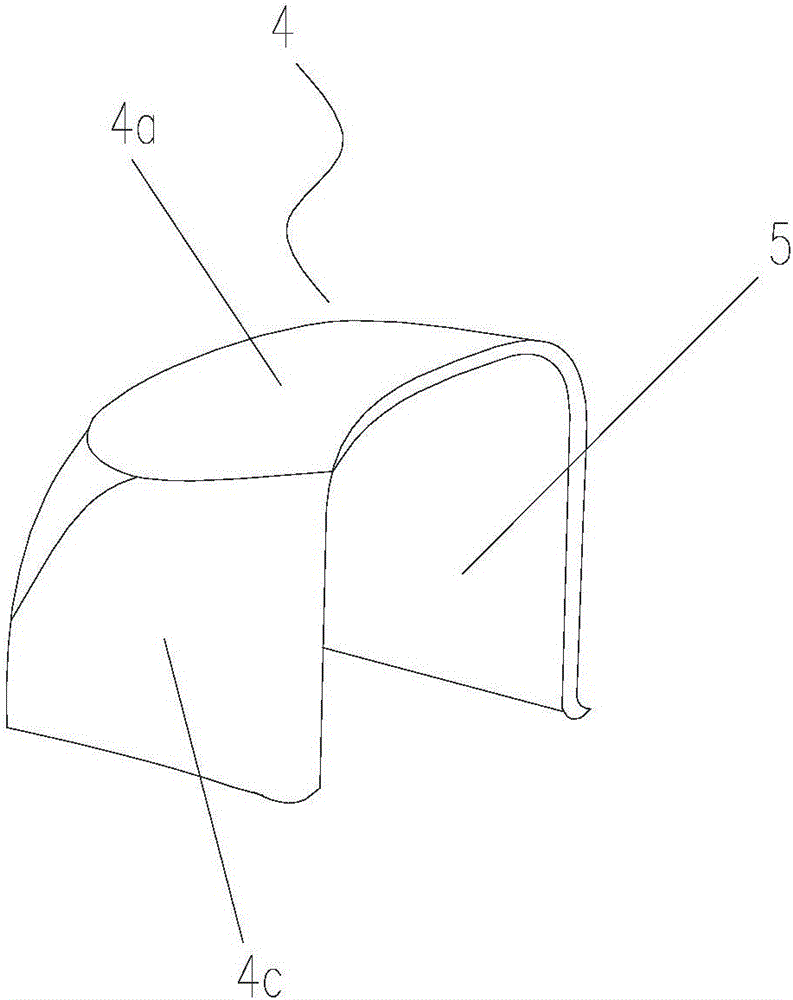

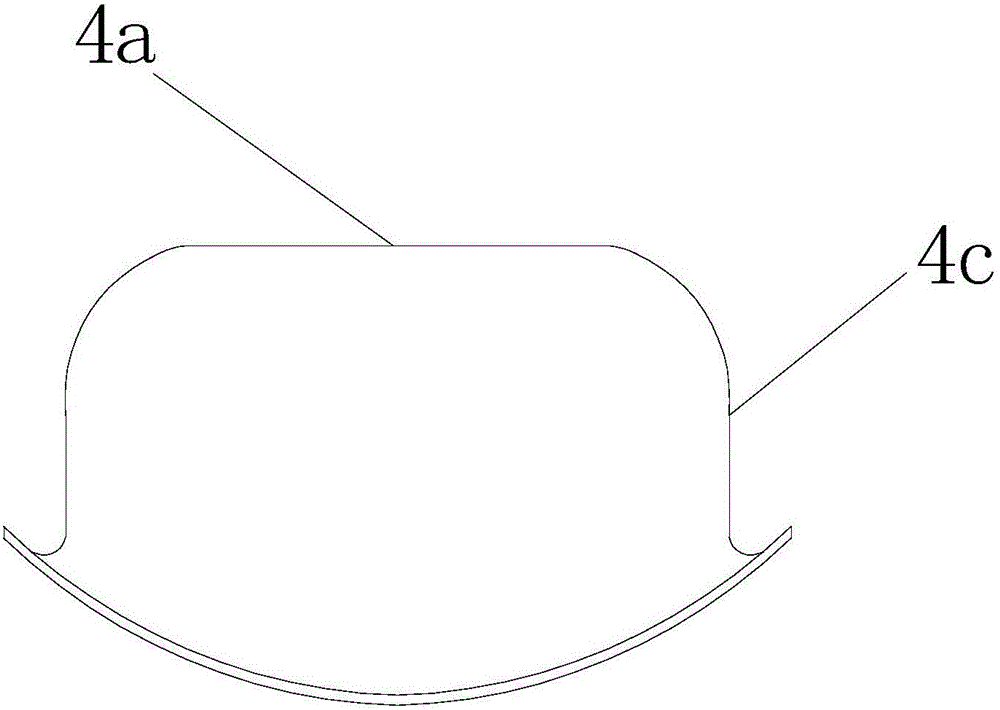

[0021] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a structural schematic diagram of the shroud in the present invention, image 3 is the rear view of the shroud, Figure 4 It is a top view of the shroud, as shown in the figure, the enhanced muffler in this embodiment includes a cylinder body 1, a resonance chamber 2 and an expansion chamber 3 located in the cylinder body 1, and the expansion chamber 3 is provided with an engine exhaust gas inlet , and the expansion chamber 3 is provided with a guide cover 4 for guiding the engine exhaust gas entering the expansion chamber 3 to the direction of the resonance chamber 2; through the setting of the guide cover 4, the engine exhaust gas entering the expansion chamber 3 can be controlled Conduct flow diversion to prevent the air flow of the engine exhaust gas from directly acting on the side wall of the shroud 4. At the same time, the shroud 4 directs the air flow to the direction of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com