Composite ink, preparation method thereof, and device

A technology of ink and nano-metal particles, which is applied in the manufacture of electrical solid devices, semiconductor devices, semiconductor/solid-state devices, etc., can solve problems such as light quenching of luminescent materials, physical or chemical changes and damage of other structures of devices, and achieve improved luminescence efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

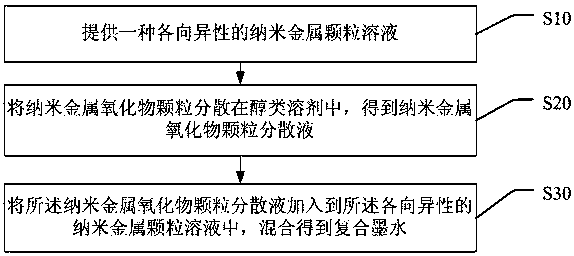

[0028] See figure 1 , figure 1 It is a flowchart of a preferred embodiment of a method for preparing a composite ink according to the present invention, as shown in the figure, which includes the steps:

[0029] S10. Provide an anisotropic nano metal particle solution;

[0030] S20: Disperse the metal oxide particles in an alcohol solvent to obtain a nano metal oxide particle dispersion;

[0031] S30. Adding the nano metal oxide particle dispersion to the anisotropic nano metal particle solution, and mixing to obtain a composite ink.

[0032] Specifically, inkjet printing technology, as an effective way for the industrialization and large-scale production of existing thin film display devices, can significantly increase the production capacity of thin film display devices and reduce their production costs. However, because inkjet printing equipment requires high physical and chemical properties of the ink, such as suitable boiling point, viscosity, surface tension, and uniformly dispe...

Embodiment 1

[0057] A composite ink includes nano titanium oxide particles and nano silver rod-shaped particles dispersed in ethanol. The preparation method of the composite ink includes:

[0058] Prepare 100 mL ethanol solution of nano titanium oxide particles with a concentration of 30 mg / mL;

[0059] Prepare 5 mL of ethanol solution of 20 mg / mL silver nano rod-shaped particles protected by citrate;

[0060] Under vigorous stirring, add dropwise the ethanol solution of nano silver rod-shaped particles to the ethanol solution of nano titanium oxide particles, and continue stirring for 24 hours at room temperature;

[0061] It is washed repeatedly with ethanol for 3 times, and then redispersed with ethanol to obtain nano-silver rod-shaped particles-nano-titanium oxide composite ink.

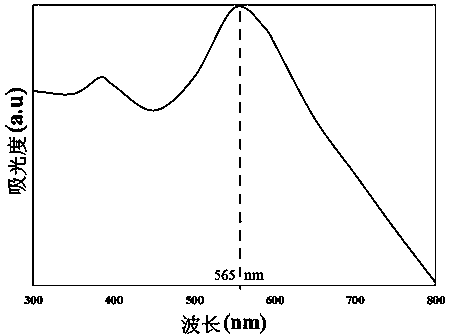

[0062] Deposit the above-mentioned composite ink into a film, and test its ultraviolet-visible light spectrum, such as figure 2 As shown, after the composite ink is formed into a film, there is a strong peak with a ha...

Embodiment 2

[0068] A composite ink includes nano titanium oxide particles and nano gold rod-shaped particles dispersed in ethanol. The preparation method of the composite ink includes:

[0069] Prepare 100 mL ethanol solution of nano titanium oxide particles with a concentration of 30 mg / mL;

[0070] Prepare 5 mL ethanol solution of 3 mg / mL gold nanorod-shaped particles protected by citrate;

[0071] Under vigorous stirring, add dropwise the ethanol solution of nano gold rod-shaped particles to the ethanol solution of nano titanium oxide particles, and continue stirring for 24 hours at room temperature;

[0072] It is washed repeatedly with ethanol for 3 times, and then redispersed with ethanol to obtain nano-gold rod-shaped particles-nano-titanium oxide composite ink.

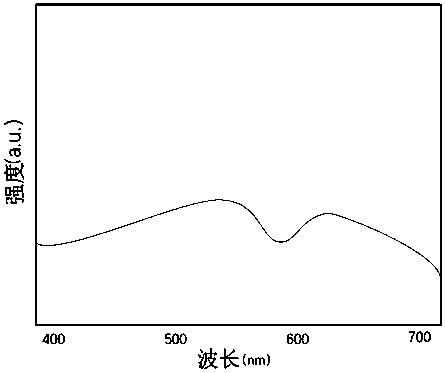

[0073] The above composite ink was deposited into a film, and its ultraviolet-visible light spectrum was tested. It was found that after the composite ink was formed, there was a strong peak with a half-value width of 13nm at 550 n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com