Honeycomb body with structured sheet material

A technology of honeycomb body and plate, which is applied in the application field of honeycomb body in the automotive field, which can solve the problems of honeycomb body and other problems, and achieve the effect of improving bending rigidity and shape stability, optimizing durability and reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

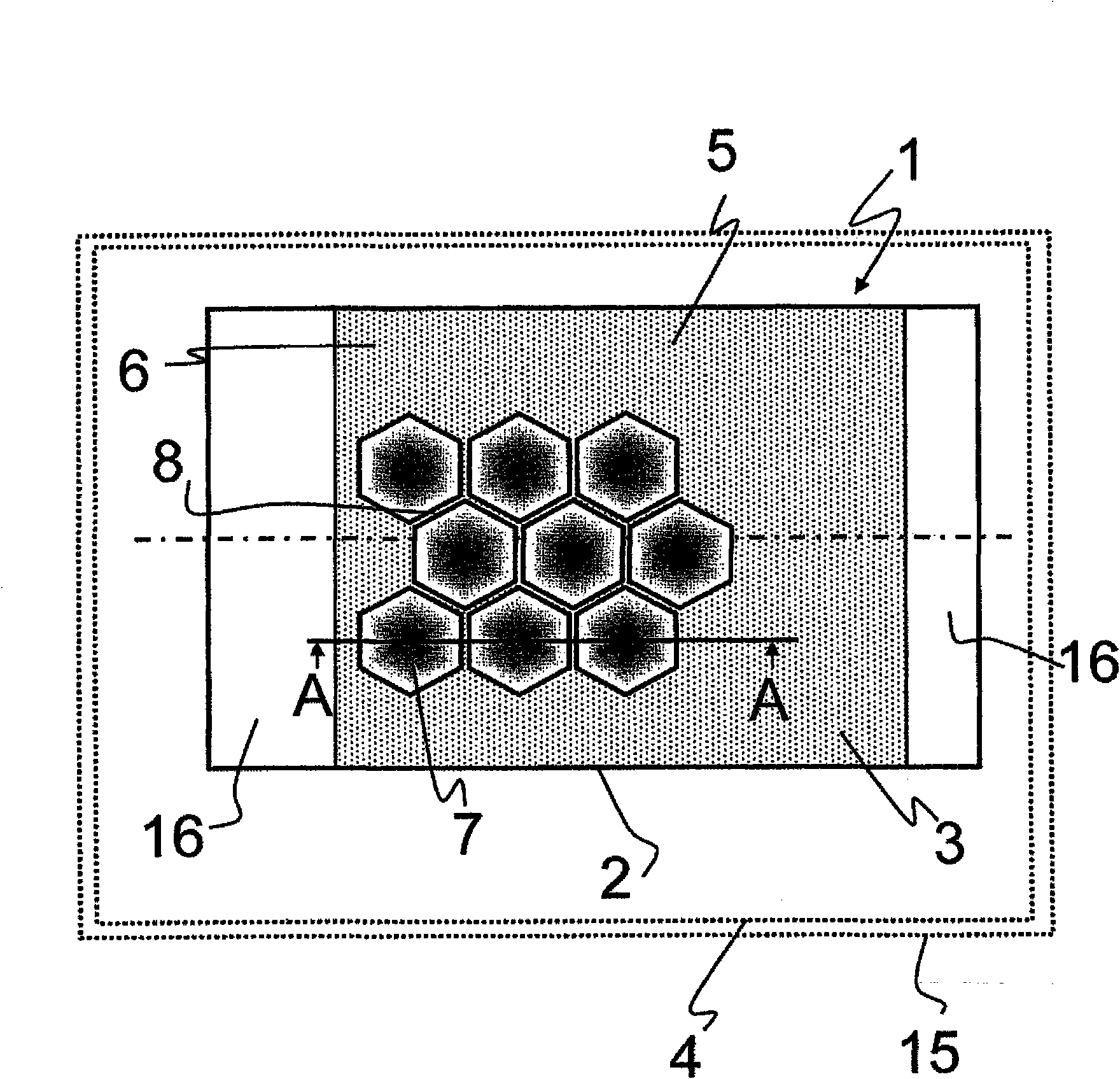

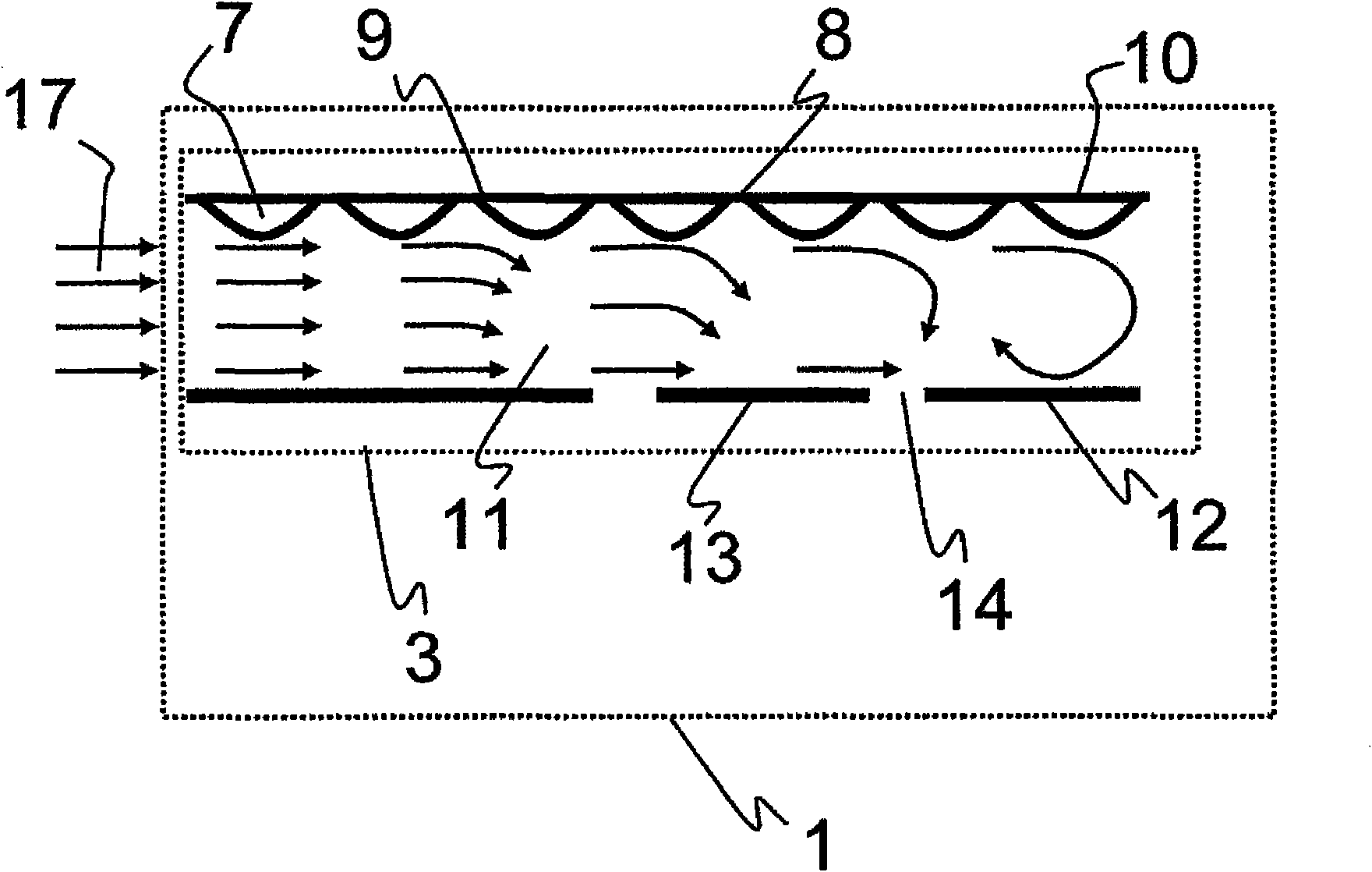

[0041] figure 1 A honeycomb body 1 is shown schematically as a component in an exhaust gas purification system 4 of a motor vehicle 15 (only shown here). Here, the honeycomb body 1 is formed from a housing 2 and a honeycomb structure 3 (only shown here) arranged in the housing 2 . In this case, the housing is formed from a sheet metal 5 with projections 7 and a regular edge profile 8 (only partially shown).

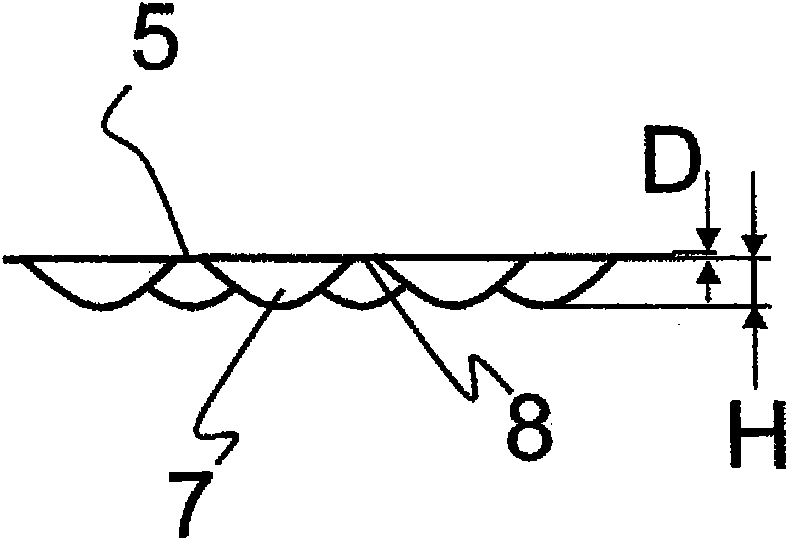

[0042] In this case, the housing 2 has a section 6 running around the circumference of the housing 2 , in which the sheet metal 5 is formed solely by the projection 7 and the edge contour 8 . Here, the edge contours 8 are each completely at the periphery The protrusion 7 is surrounded. The section 6 terminates at a connection region 16 of the housing 2 with the widened edge profile 8 (connection). figure 2 to follow figure 1 The cross-section taken along the line A-A shows by way of example the shape selected here for the projection 7 and the edge contour 8 . In a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com