Method for recovering sodium sulfate by utilizing sodium sulfate containing waste salt residue

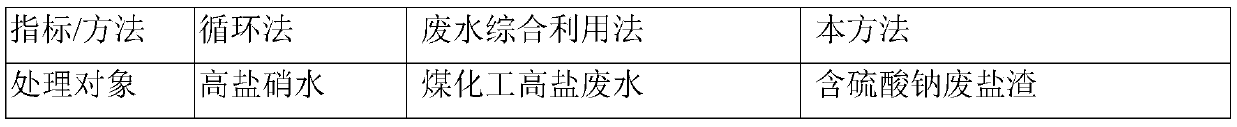

A technology containing sodium sulfate and sodium sulfate, which is applied in the field of hazardous waste resource treatment, can solve the problems of high operation requirements, low product recovery rate, high treatment cost, etc., and achieve good environmental and social benefits, high product recovery rate, The effect of low running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

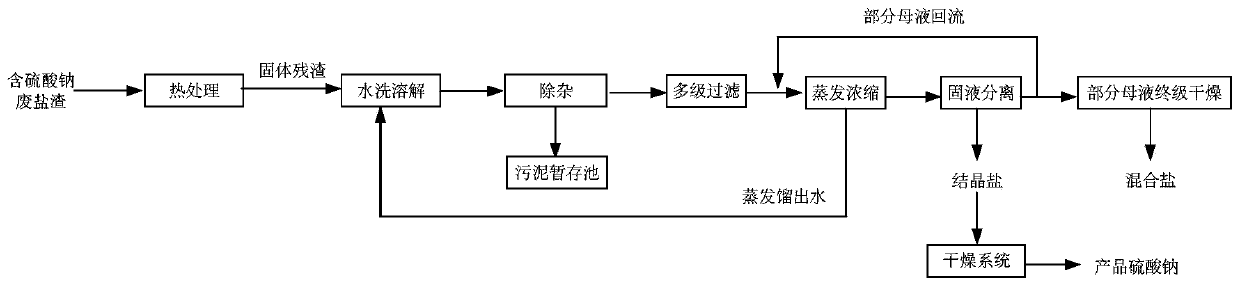

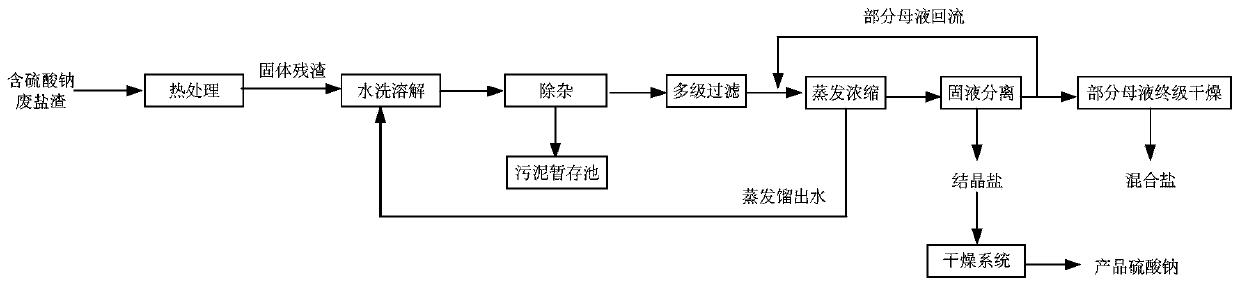

Method used

Image

Examples

Embodiment 1

[0023] Get 131t of waste cooking agent residue in the pulp production process of a paper mill, after analyzing the sodium sulfate content in the raw material residue is about 81.05% (wt%), the sodium chloride content is about 1.15% (wt%), and the organic matter content is about 10.67% (wt%) , the water content is about 5.17% (wt%), and metal impurities such as calcium and magnesium are 1.13% (wt%). Choose heat treatment-dissolving water washing-multi-stage purification and impurity removal-thermal evaporation, concentration and crystallization combined system process route for treatment.

[0024] After heat treatment (treatment temperature 300°C), after the decomposition of organic matter is completed, the liquid-solid ratio (v / w) of 8:1 is used for dissolution and water washing, and the solution is purified, impurity-removed and multi-stage filtered, evaporated, concentrated and crystallized to obtain about 104.1 tons of sulfuric acid The sodium product has reached the first-...

Embodiment 2

[0026] Get 357t of the waste coagulant residue of a certain textile factory, after analyzing the sodium sulfate content in the raw material residue is about 78.86% (wt%), the sodium chloride content is about 0.89% (wt%), the organic content is about 6.84% (wt%), and the moisture content is about 78.86% (wt%). About 9.90% (wt%), metal impurities such as calcium and magnesium 2.17% (wt%). Choose heat treatment-dissolving water washing-multi-stage purification and impurity removal-thermal evaporation, concentration and crystallization combined system process route for treatment.

[0027]After heat treatment (treatment temperature 650°C), after the decomposition of organic matter is completed, the liquid-solid ratio (v / w) of 3:1 is used for dissolution and water washing, and the solution is purified, impurity-removed and multi-stage filtered, evaporated, concentrated and crystallized to obtain about 276 tons of sulfuric acid The sodium product has reached the first-class product o...

Embodiment 3

[0029] Get 413t of waste coagulant residues from a certain dyestuff production enterprise. After analyzing the sodium sulfate content in the raw material residues is about 83.57% (wt%), the sodium chloride content is about 0.46% (wt%), and the organic content is about 7.15% (wt%). The content is about 8.10% (wt%), and metal impurities such as calcium and magnesium are 0.72% (wt%). Choose heat treatment-dissolving water washing-multi-stage purification and impurity removal-thermal evaporation, concentration and crystallization combined system process route for treatment.

[0030] After heat treatment (treatment temperature 500°C), after the organic matter is decomposed, it is dissolved and washed with a liquid-solid ratio (v / w) of 5:1. After the solution is purified, impurity-removed and multi-stage filtered, it is evaporated, concentrated and crystallized to obtain about 335 tons of sulfuric acid. The sodium product has reached the first-class product of category III in the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com