Combined catalyst used for preparing light olefins and use method thereof

A technology of combining catalysts and carbon olefins, applied in molecular sieve catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as large fixed investment, low selectivity, and complex reaction devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

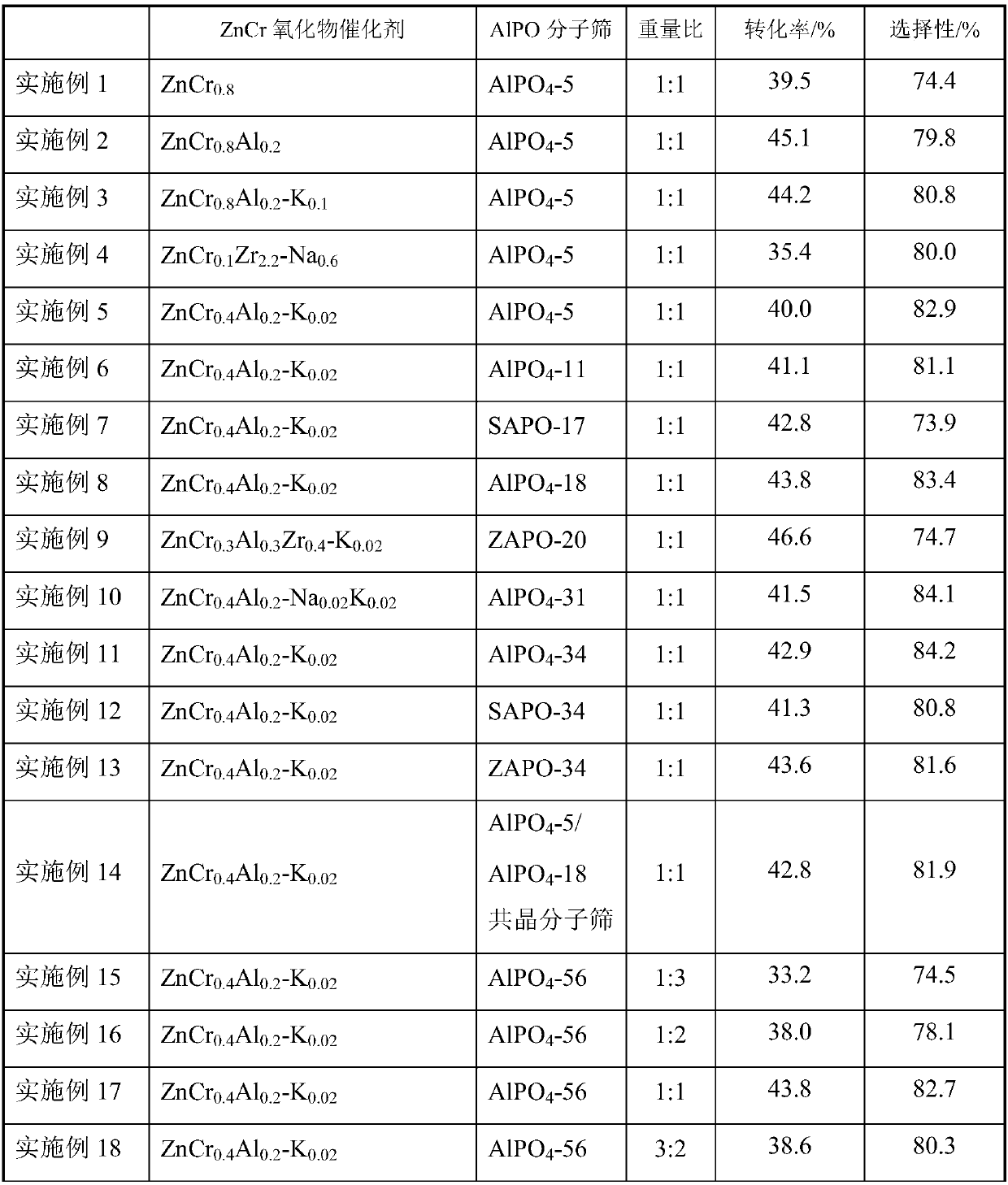

Examples

Embodiment 1

[0041] ZnCr 0.8 Catalyst is prepared as follows:

[0042] Weigh 1 mol of zinc nitrate and 0.8 mol of chromium nitrate, dissolve them in 1000 mL of distilled water, then dissolve 5 mol of NaOH in 1000 mL of water, co-precipitate the two aqueous solutions, age at 70°C for 3 hours, and filter at 100°C Dry overnight at 400°C and bake at 400°C for 12 hours to obtain ZnCr 0.8 catalyst.

[0043] AlPO 4 -5 catalyst is prepared as follows:

[0044] Pseudoboehmite, phosphoric acid, and tri-n-propylamine (TPA) were used as aluminum source, phosphorus source, and template agent respectively, and the molar ratio of Al 2 o 3 :P 2 o 5 :TPA:Ethanol:H 2 O=1:1.2:2.66:80:1000, add to the reactor and age for 2 hours, stir and crystallize at 190°C for 48 hours, wash the obtained solid with deionized water until neutral, separate the solid, dry it, and put it in a muffle furnace Calcined at 550°C for 6 hours to obtain AlPO 4 -5 molecular sieves.

[0045] 0.75 g of prepared ZnCr 0.8 Cata...

Embodiment 2

[0047] ZnCr 0.8 Al 0.2 Catalyst is prepared as follows:

[0048] Weigh 1 mol of zinc nitrate, 0.8 mol of chromium nitrate, 0.2 mol of aluminum nitrate, dissolve in 1000 mL of distilled water, then dissolve 5 mol of NaOH in 1000 mL of water, co-precipitate the two aqueous solutions, and age at 70 ° C for 3 hours , dried overnight at 100°C after filtration, and calcined at 400°C for 12h to obtain ZnCr 0.8 Al 0.2 catalyst.

[0049] AlPO 4 -5 Catalyst is prepared by [embodiment 1].

[0050] 0.75 g of prepared ZnCr 0.8 Al 0.2 Catalyst and 0.75 g of prepared AlPO 4 -5 mixed, packed into a quartz reaction tube with an inner diameter of 6 mm, the (n 氢气 :n 一氧化碳 =50:50) into the reaction tube, into the catalytic bed reaction, the reaction temperature is 400 ℃, the reaction system pressure is 4MPa, the gas volume space velocity is 4,000h -1 The reaction of syngas to light olefins is carried out under the conditions. The activity evaluation results are shown in Table 1.

Embodiment 3

[0052] ZnCr 0.8 Al 0.2 -K 0.1 Catalyst is prepared as follows:

[0053] Weigh 1 mol of zinc nitrate, 0.8 mol of chromium nitrate, 0.2 mol of aluminum nitrate, dissolve in 1000 mL of distilled water, then dissolve 5 mol of NaOH in 1000 mL of water, co-precipitate the two aqueous solutions, and age at 70 ° C for 3 hours , dried overnight at 100°C after filtration, and calcined at 400°C for 12h. After the calcination is completed, the catalyst intermediate is loaded with 0.05 mol of K 2 CO 3 , dried overnight at 80°C, and fired at 400°C for 1 hour to obtain ZnCr 0.8 Al 0.2 -K 0.1 catalyst.

[0054] AlPO 4 -5 Catalyst is prepared by [embodiment 1].

[0055] 0.75 g of prepared ZnCr 0.8 Al 0.2 -K 0.1 Catalyst and 0.75 g of prepared AlPO 4 -5 mixed, packed into a quartz reaction tube with an inner diameter of 6 mm, the (n 氢气 :n 一氧化碳 =50:50) into the reaction tube, into the catalytic bed reaction, the reaction temperature is 400 ℃, the reaction system pressure is 4MPa,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com