Preparation and application of PEG/Dex dual-aqueous-phase based calcium carbonate/calcium alginate composite microcapsules

A technology of calcium alginate and calcium carbonate, which is applied in the direction of microsphere preparation, microcapsule preparation, application, etc., and can solve the problems that restrict the wide application of calcium alginate microcapsules, the batch of recycled use is not high, and the mechanical strength of microcapsules is poor. , to achieve the effect of not easy to swell during storage time, more cycle times, and less equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

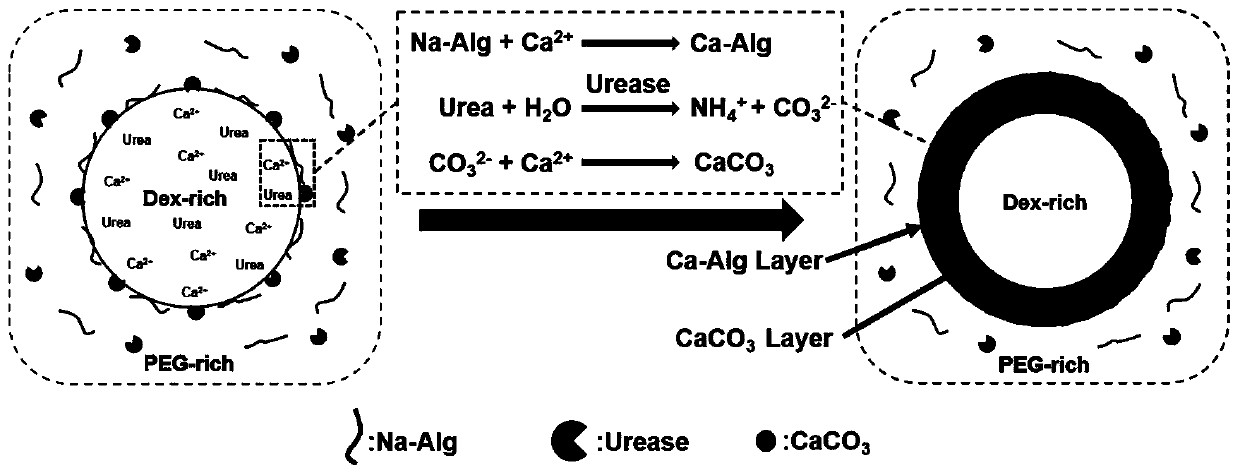

[0046] figure 1 It is the mechanism of calcium carbonate / calcium alginate composite microcapsules produced by the interface reaction of two-phase liquid droplets in the present invention, that is, a calcium carbonate / calcium alginate composite microcapsule prepared based on PEG / Dex two-water phase and its preparation method Include the following steps:

[0047] 1. Configure polyethylene glycol / dextran aqueous two-phase

[0048] (1) prepare 16wt% polyethylene glycol solution, molecular weight 8kDa, denoted as A solution;

[0049] (2) prepare 16wt% dextran solution, molecular weight 500kDa, denoted as B solution;

[0050] (3) Take the same volumes of solution A and solution B and mix them well, let stand for 18-24 hours to separate the phases, extract the upper phase and lower phase respectively and transfer them to two beakers for later use, and record them as solution C and solution D respectively.

[0051] 2. Preparation of calcium carbonate / calcium alginate composite micr...

Embodiment 2

[0057] 1. Configure polyethylene glycol / dextran aqueous two-phase

[0058] (1) prepare 16wt% polyethylene glycol solution, molecular weight 8kDa, denoted as A solution;

[0059] (2) prepare 16wt% dextran solution, molecular weight 500kDa, denoted as B solution;

[0060] (3) Take the same volumes of solution A and solution B and mix them well, let stand for 18-24 hours to separate the phases, extract the upper phase and lower phase respectively and transfer them to two beakers for later use, and record them as solution C and solution D respectively.

[0061] 2. Preparation of calcium carbonate / calcium alginate composite microcapsules

[0062] (4) Solution E: Weigh 0.108g of sodium alginate and 0.03g of urease, add them to 10mL of solution C, mix well, and let stand as a receiving solution;

[0063] (5) Solution F: Weigh 0.02g of anhydrous calcium chloride and 0.02g of urea and dissolve them in 2mL of solution D, mix well, and let stand as an injection;

[0064] (6) Use an or...

Embodiment 3

[0068] 1. Configure polyethylene glycol / dextran aqueous two-phase

[0069] (1) prepare 16wt% polyethylene glycol solution, molecular weight 8kDa, denoted as A solution;

[0070] (2) prepare 16wt% dextran solution, molecular weight 500kDa, denoted as B solution;

[0071] (3) Take the same volumes of solution A and solution B and mix them well, let stand for 18-24 hours to separate the phases, extract the upper phase and lower phase respectively and transfer them to two beakers for later use, and record them as solution C and solution D respectively.

[0072] 2. Preparation of calcium carbonate / calcium alginate composite microcapsules

[0073] (4) Solution E: Weigh 0.108g of sodium alginate and 0.03g of urease, add them to 10mL of solution C, mix well, and let stand as a receiving solution;

[0074] (5) Solution F: Weigh 0.06g of anhydrous calcium chloride and 0.02g of urea and dissolve them in 2mL of solution D, mix well, and let stand as an injection;

[0075] (6) Use an ordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com