Preparation method of lime and carrot protein beverage

A carrot and carrot juice technology, applied in the field of preparation of lime carrot protein drink, can solve problems such as carbon dioxide foam control, achieve the effects of reducing phenolic compounds, high yield, and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of lime carrot protein drink comprises,

[0036] mixing protein concentrate with a protein concentration of 10% by weight, lime juice, carrot juice, a foam control agent, and a certain amount of pH regulator for providing a pH of 2 in water, thereby obtaining a blend;

[0037] Heat the blend to a temperature of 140°F for 60 seconds;

[0038] Cool the blend to a temperature below 40°F within 5 minutes;

[0039] carbon dioxide is added to the blend to obtain a carbonated protein drink, wherein the amount of dissolved carbon dioxide in the blend is 300 ppm; and

[0040] Cavitation of liquids containing carbonic acid gas under pressure.

[0041] Wherein, the weight percent content of each component is respectively: 20% of protein concentrate, 2% of lime juice, 5% of carrot juice, 2% of foam control agent, 1% of pH regulator; further containing additives, L-glutamine 1 %, oligofuran polysaccharide 1.5%.

[0042] The foam control agent contains 75% ...

Embodiment 2

[0050] The preparation method of lime carrot protein drink comprises,

[0051] mixing a protein concentrate with a protein concentration of 16% by weight, lime juice, carrot juice, a foam control agent, and a certain amount of pH regulator to provide a pH of 3.4 in water, thereby obtaining a blend;

[0052] Heat the blend to a temperature of 166°F for 60 seconds;

[0053] Cool the blend to a temperature below 40°F over a period of 6 minutes;

[0054] carbon dioxide is added to the blend to obtain a carbonated protein drink, wherein the amount of dissolved carbon dioxide in the blend is 3800 ppm; and

[0055] Cavitation of liquids containing carbonic acid gas under pressure.

[0056] Wherein, the weight percent content of each component is respectively: 32% of protein concentrate, 5% of lime juice, 11% of carrot juice, 3.6% of foam control agent, 2% of pH regulator; further contains additives, 1% of taurine, Oat Fiber 3%, Malic Acid 1.2%, Aspartame 0.8%; Foam Control Contain...

Embodiment 3

[0067] 1. Sensory evaluation:

[0068] The lime carrot protein drink prepared in Example 2 has high clarity, fine air bubbles, and good carbon dioxide retention; while the drink in Comparative Example 2 has a little turbidity and a strong sense of carbonic acid, and it feels painful in the mouth, and the carbonic acid sense is immediate. This indicates that adding leaf alcohol and methyl formate to the enzymatic hydrolysis solution during the process of obtaining the protein solution can reduce the interference of phytic acid on the properties of the protein, and at the same time help to strengthen the cavitation effect of the liquid and make the carbon dioxide bubbles finer , with a longer holding effect.

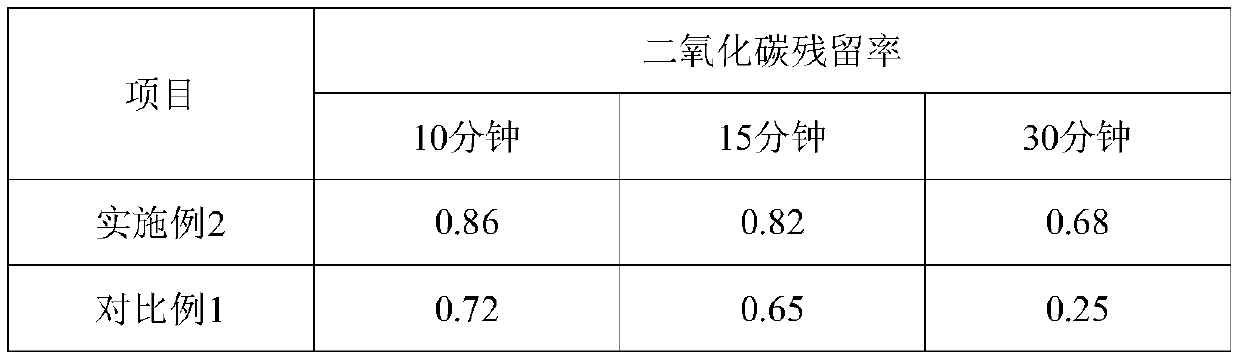

[0069] 2. Evaluate the change over time of the amount of carbon dioxide in the carbonated beverage of the present invention:

[0070] The carbonated beverage (glass bottle) prepared in Example 2 and Comparative Example 1 was soaked in a 20°C constant temperature tank for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com