A colored dispersion liquid, a colored photosensitive resin composition, a pattern layer, a color filter and a display device

A photosensitive resin and dispersing resin technology, applied in optics, instruments, filters, etc., can solve the problems of insufficient improvement in solvent resistance and storage stability, and achieve excellent storage stability, reliability, and elasticity. The effect of the response rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

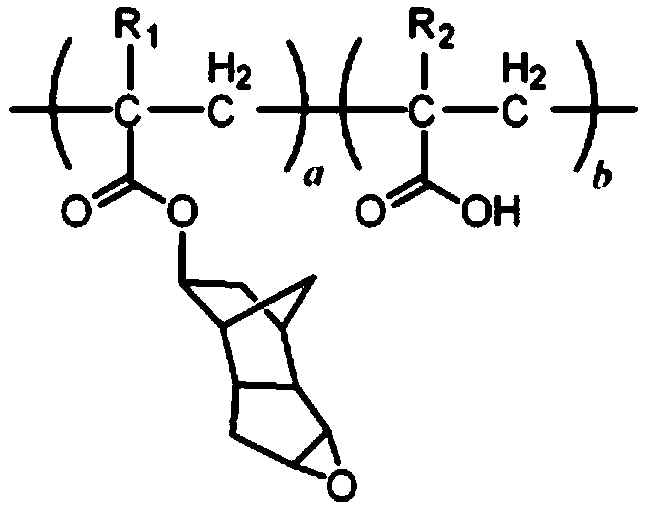

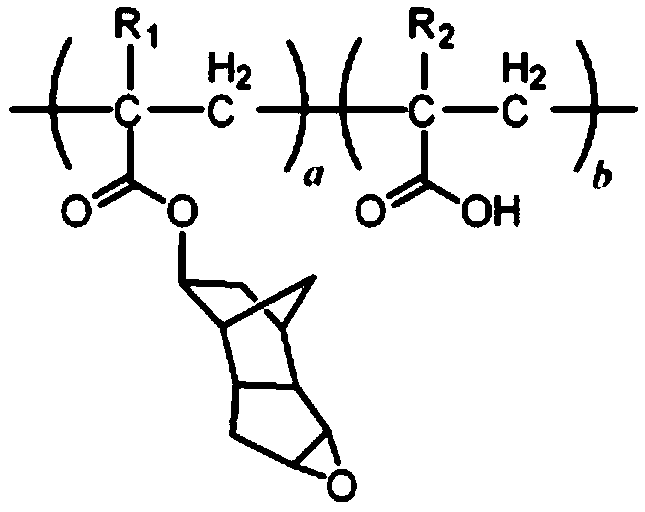

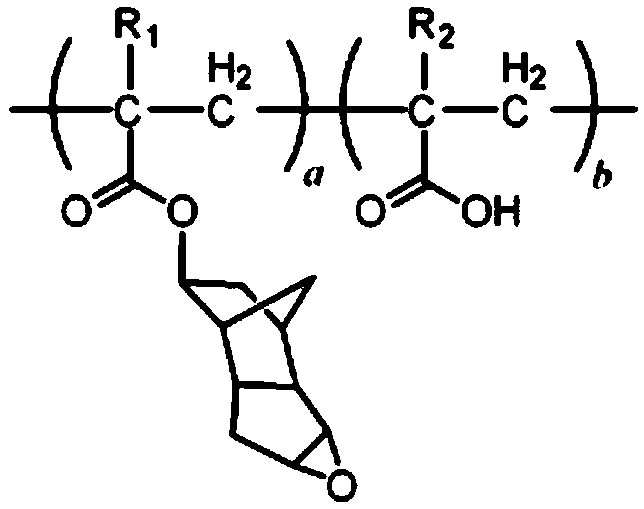

[0177] Production Example 1. Production of Dispersion Resin A1

[0178] 277 g of methoxybutyl acetate was injected|thrown-in to the separation-type flask of internal volume 1L equipped with the stirrer, thermometer, reflux condenser, dropping funnel, and nitrogen introduction tube, and it heated to 80 degreeC. Next, prepare 3,4-epoxytricyclo[5.2.1.0,2,6]decane-9-yl acrylate and 3,4-epoxytricyclo[5.2.1.0,2,6] A mixture obtained by dissolving 301 g of decan-8-yl acrylate in a molar ratio of 50:50, 49 g of methacrylic acid, and 23 g of azobisdimethylvaleronitrile in 350 g of methoxybutyl acetate mixture. The said mixed solution was dripped in the flask over 5 hours using the dropping funnel, and it reacted for 3 hours, and dispersion resin A1 [solid content (NV) 35.0 weight%] was manufactured. The acid value (dry) of the dispersed resin A1 produced above was 69.8 KOH mg / g, the weight average molecular weight (Mw) was 12,300, and the degree of dispersion (Mw / Mn) was 2.1.

manufacture example 2

[0179] Production Example 2. Production of Dispersion Resin A2

[0180] Prepare a flask equipped with a stirrer, thermometer, reflux condenser, dropping funnel, and nitrogen inlet. As a monomer dropping funnel, 14.4 parts by weight (0.2 moles) of acrylic acid, 140.8 parts by weight (0.8 moles) of benzyl methacrylate, 2.0 parts by weight of tert-butyl peroxy-2-ethylhexanoate, propylene glycol monomethyl 40.0 parts by weight of ether acetate (PGMEA) were mixed and prepared. As a chain transfer agent dropping tank, 3.0 parts by weight of n-dodecanemercaptan and 24.0 parts by weight of PGMEA were mixed and prepared. After that, 395 parts by weight of PGMEA was added to the flask, and the atmosphere in the flask was replaced with nitrogen from air, and then the temperature of the flask was raised to 90° C. while stirring. Next, the monomer and the chain transfer agent were added dropwise from the dropping funnel. The dropwise addition was performed for 4 hours each while maintai...

manufacture example 3

[0181] Production Example 3. Production of Dispersion Resin A3

[0182] Prepare a flask equipped with a stirrer, thermometer, reflux condenser, dropping funnel, and nitrogen inlet. As a monomer dropping funnel, 52.1 parts by weight (0.25 moles) of 2-phenylthioethyl acrylate, 44.0 parts by weight (0.25 moles) of benzyl methacrylate, 12.9 parts by weight (0.15 moles) of methacrylic acid, ethylene 41.3 parts by weight (0.35 mol) of methyl toluene, 4.0 parts by weight of tert-butyl peroxy-2-ethylhexanoate, and 40.0 parts by weight of PGMEA were prepared by mixing. As a chain transfer agent dropping tank, 6.0 parts by weight of n-dodecanemercaptan and 24.0 parts by weight of PGMEA were mixed and prepared. After that, 395 parts by weight of PGMEA was added to the flask, and the atmosphere in the flask was replaced with nitrogen from air, and then the temperature of the flask was raised to 90° C. while stirring. Next, the monomer and the chain transfer agent were added dropwise f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com