A kind of macroporous kaolinite and its preparation and application

A kaolinite and kaolin technology, applied in the field of kaolinite and its preparation, can solve the problems of difficult filtration, high industrial production cost, and small kaolin particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

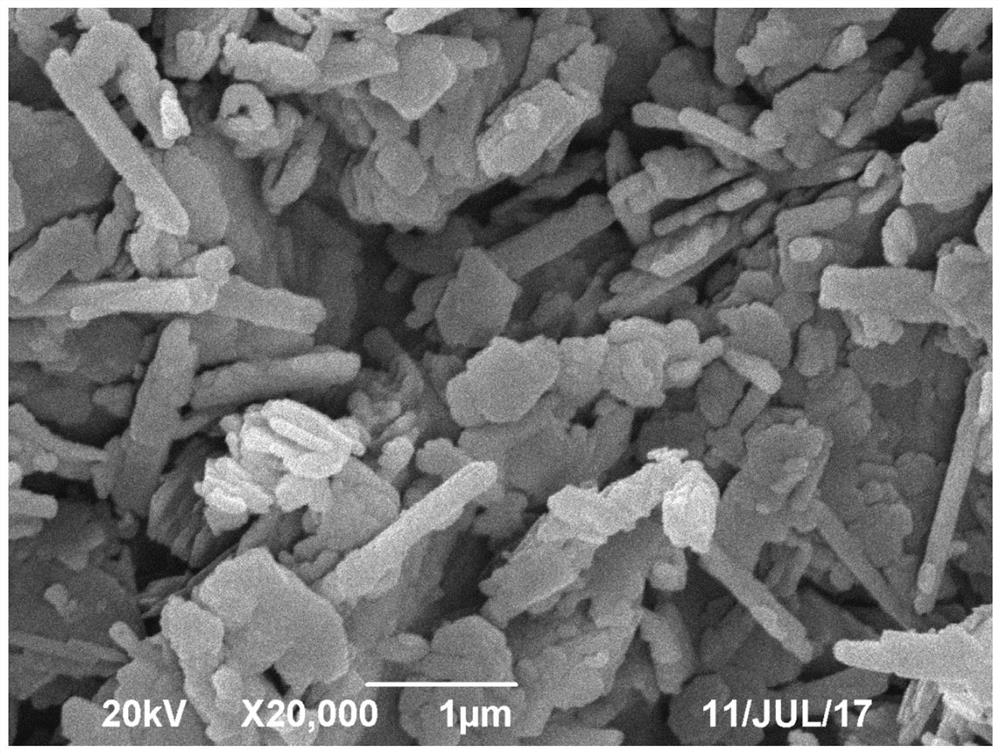

Image

Examples

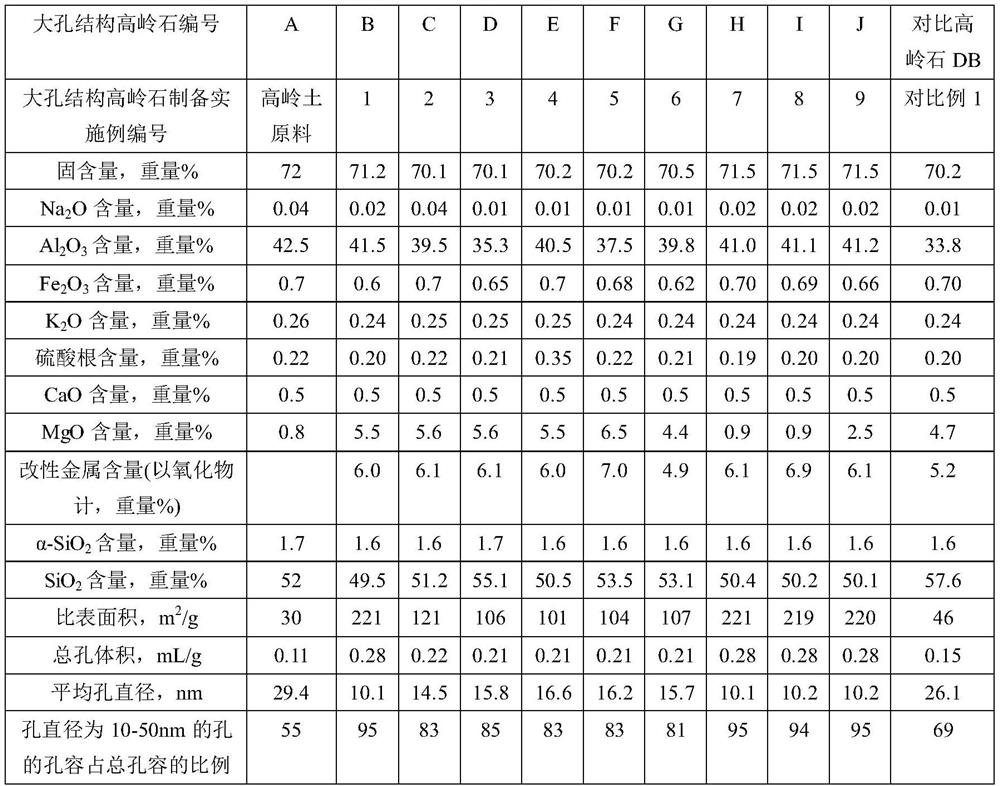

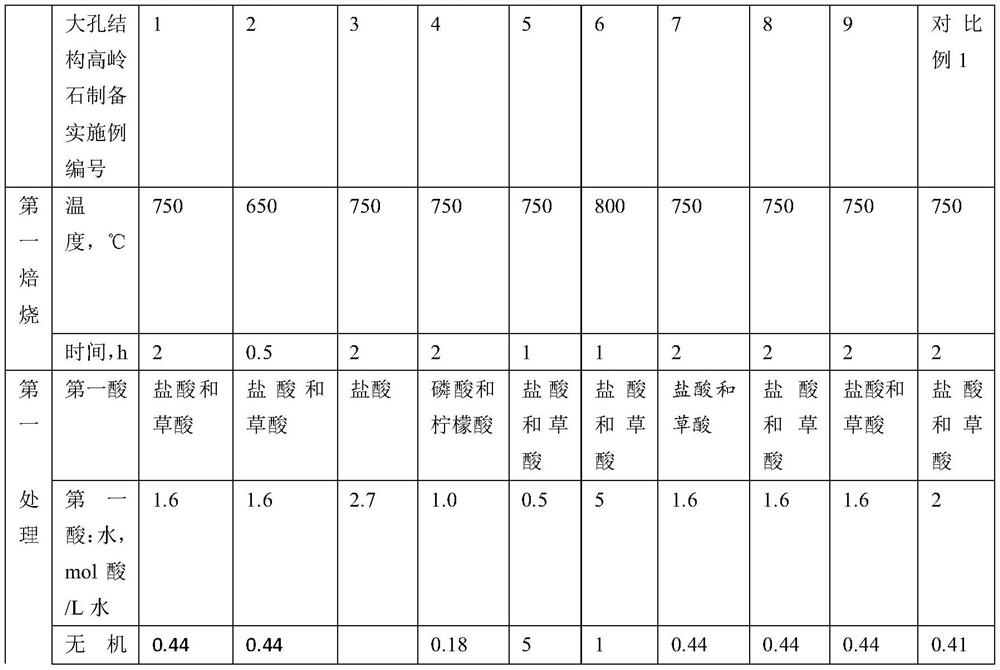

preparation Embodiment 1

[0075] Kaolin A was roasted at 750° C. for 2 hours to obtain a roasted material (called the first roasted material), and 168 g (dry basis, the same below) of the roasted material was added to decationized water (pH=3.1, the same below) and stirred to prepare To form a slurry with a solid content of 25% by weight, add 500g of hydrochloric acid with a concentration of 1mol / L, 100g of oxalic acid, and 12.00g of magnesium chloride, heat up to 70°C, stir for 1 hour, then filter to remove the mother liquor, and dry the filter cake to obtain the first step Product; 120g of the first step product was roasted at 750°C for 2 hours to obtain a roasted material (called the second roasted material), and 100g (dry basis, the same below) was added to the second roasted material and stirred with decationized water to obtain a solid content of 25 Add 200g of hydrochloric acid, 50g of oxalic acid, 50g of polyethylene glycol, and 5.00g of magnesium chloride with a concentration of 1mol / L to the s...

preparation Embodiment 2

[0077] Kaolin A was roasted at 650° C. for 0.5 hour to obtain a roasted material (referred to as the first roasted material). 168 g of the first roasted material was added to decationized water and stirred to obtain a slurry with a solid content of 25% by weight. 500g of hydrochloric acid, 100g of oxalic acid, and 12.00g of magnesium chloride are heated to 70°C, stirred for 1 hour, then filtered to remove the mother liquor, and the filter cake is dried to obtain the product of the first step; 120g of the product of the first step is roasted at 650°C for 0.5 hours to obtain Roasted material (referred to as the second roasted material), 100g of the second roasted material is added acidic water (decationized water) and stirred to obtain a slurry with a solid content of 25% by weight, adding 200g of hydrochloric acid and 50g of oxalic acid with a concentration of 1mol / L, polyethylene glycol Diol 50g, magnesium chloride 5.00g, heat up to 70°C, stir for 1 hour, then filter to remove ...

preparation Embodiment 3

[0079] Roasting clay A at 750° C. for 2 hours to obtain a roasted material (called the first roasted material), 168 g of the first roasted material was added with deionized water and stirred to obtain a slurry with a solid content of 25% by weight. Hydrochloric acid 500g, magnesium chloride 12.00g, be warming up to 70 ℃, stirring time 1 hour, then filter and remove mother liquor, filter cake oven dry, obtain the first step product; 120g first step product 120g were roasted at 750 ℃ for 2 hours to obtain roasted material ( (referred to as the second roasting material), 100g of the second roasting material is added with deionized water and stirred to obtain a slurry with a solid content of 25% by weight, adding 200g of hydrochloric acid, 50g of polyethylene glycol, and 5.00g of magnesium chloride with a concentration of 5mol / L, and heating up to 70°C, stirred for 1 hour, then filtered to remove the mother liquor, and dried the filter cake to obtain kaolinite D with a macroporou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com