Pipe expanding machine capable of carrying out clamping

A technology of pipe expanding machine and clamping position, applied in the field of pipe expanding machine, can solve the problems of low efficiency of manual operation, misalignment of pipelines, time-consuming and labor-intensive, etc., and achieve the effect of simple structure, avoiding pipeline jamming, and preventing shaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

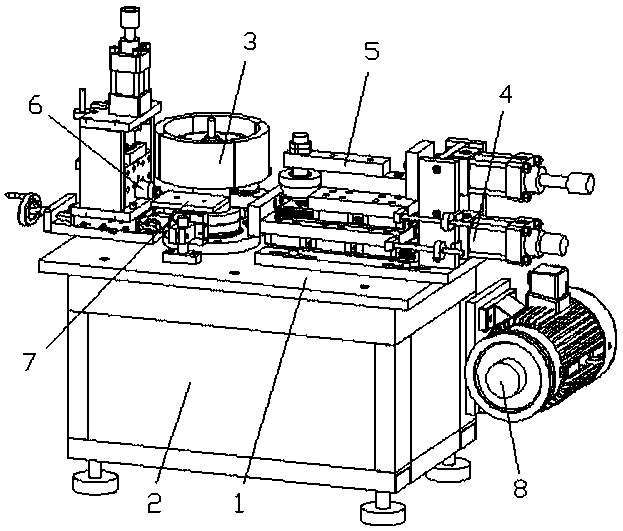

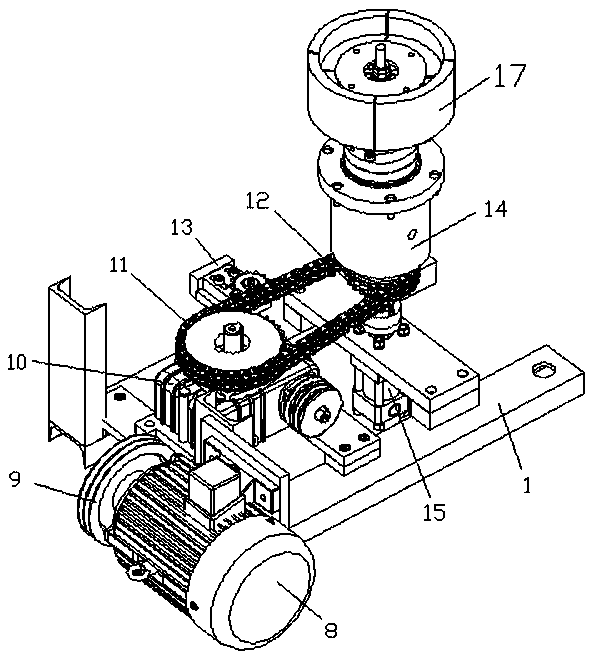

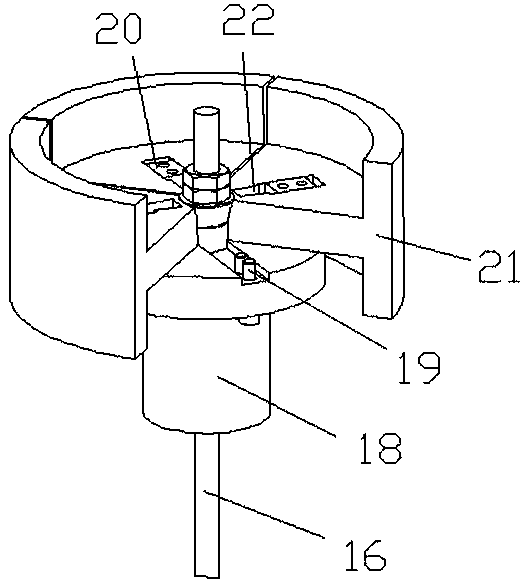

[0038] Such as Figure 1-Figure 8 As shown, the specific structure of the present invention is: a pipe expander capable of clamping positions, which includes a frame 1 and a power distribution control box 2, the frame 1 is provided with a pipe expansion loading device 3, the The described tube expanding and loading device 3 includes a loading tube expander 17 matched with the pipe, the bottom of the loading tube expander 17 is connected with a loading shaft 16, and the loading shaft 16 passes through the sprocket wheel 12 and The chain 11 is connected with the output shaft of the power commutator 10, and the input shaft of the power commutator 10 is connected to the pipe expanding rotating motor 8 through the transmission wheel 9 and the transmission belt. The material loading turntable 18 connected to the material rotating shaft 16, the loading fixing slide block 20 is uniformly arranged along the circumference through the loading fixing bolt 19 on the described loading turni...

Embodiment 2

[0047] Such as Figure 1-Figure 7 , Figure 9 As shown, the specific structure of the present invention is: a pipe expander capable of clamping positions, which includes a frame 1 and a power distribution control box 2, the frame 1 is provided with a pipe expansion loading device 3, the The described tube expanding and loading device 3 includes a loading tube expander 17 matched with the pipe, the bottom of the loading tube expander 17 is connected with a loading shaft 16, and the loading shaft 16 passes through the sprocket wheel 12 and The chain 11 is connected with the output shaft of the power commutator 10, and the input shaft of the power commutator 10 is connected to the pipe expanding rotating motor 8 through the transmission wheel 9 and the transmission belt. The material loading turntable 18 connected to the material rotating shaft 16, the loading fixing slide block 20 is uniformly arranged along the circumference through the loading fixing bolt 19 on the described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com