Coating method of high-nickel ternary material

A high-nickel ternary material and coating technology, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of high residual alkali on the surface of the material, unstable structure, high pH value, etc., and improve the rate discharge performance , maintain integrity, reduce the effect of material PH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Ternary NCM811 material coating two burnt

[0023] Get one part of LiNi0.8Co0.1Mn0.1O2, a sintered product of ternary 811 material, and fully mix it with 0.005 part (weight ratio) of fine powder EMD material;

[0024] The mixed material is kept moist in the air at 700 degrees Celsius for 3-5 hours to obtain the finished ternary NCM811 material.

Embodiment 2

[0025] Embodiment 2: Coated dicalcination of nickel-cobalt-aluminum NCA cathode material

[0026] Get a part of the nickel-cobalt-aluminum NCA positive electrode material one-sintered product, fully mix it with the fine powder EMD material of 0.005 part (weight ratio);

[0027] The mixed material is kept moist in the air at 700 degrees Celsius for 3-5 hours to obtain the finished ternary NCM811 material.

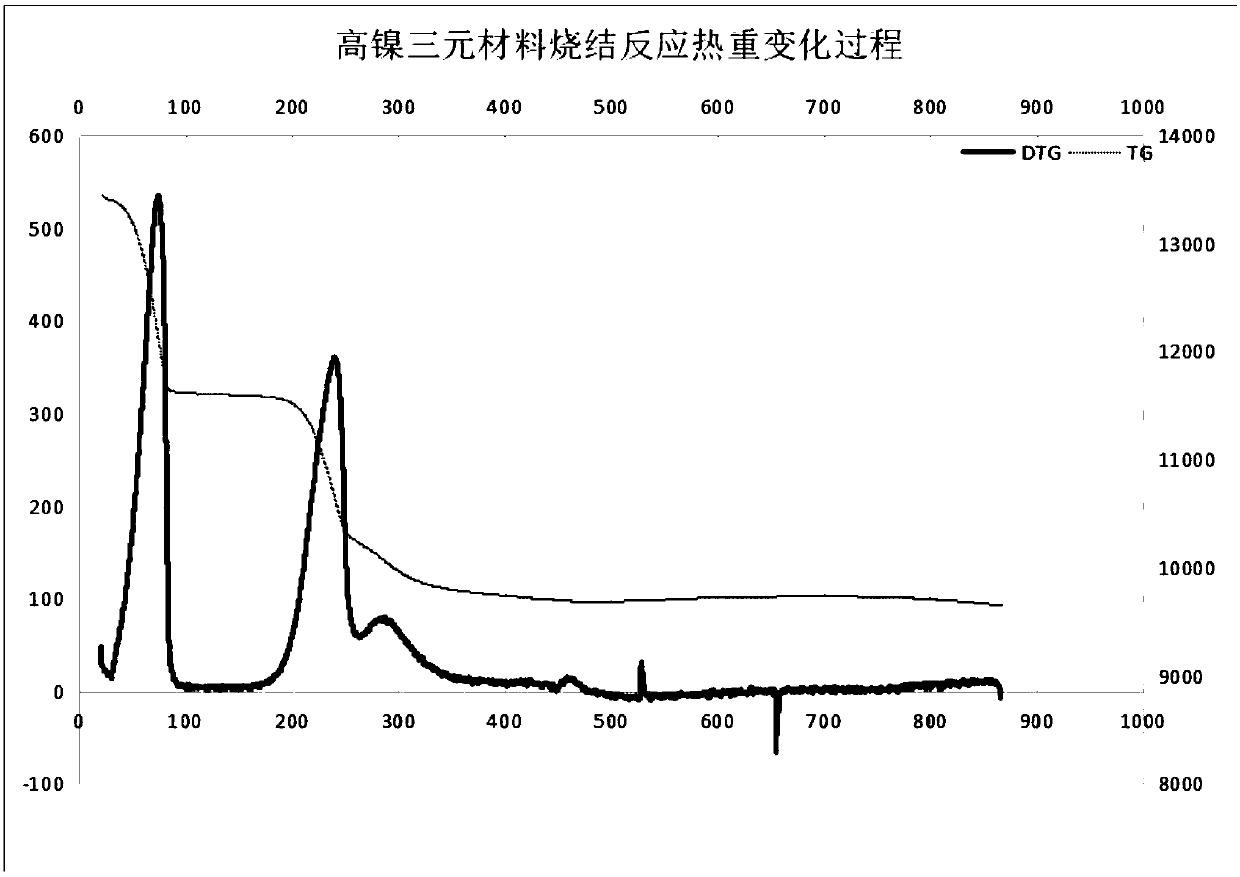

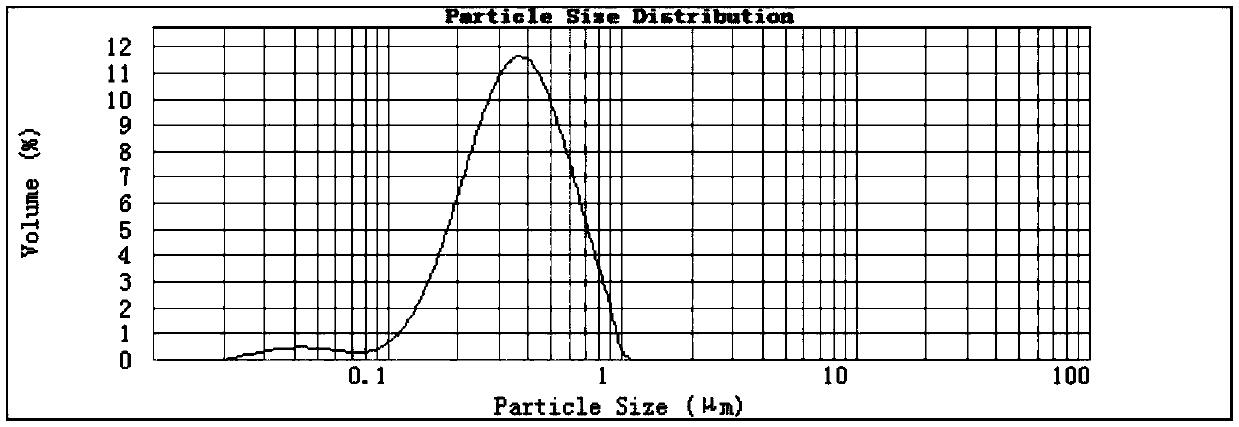

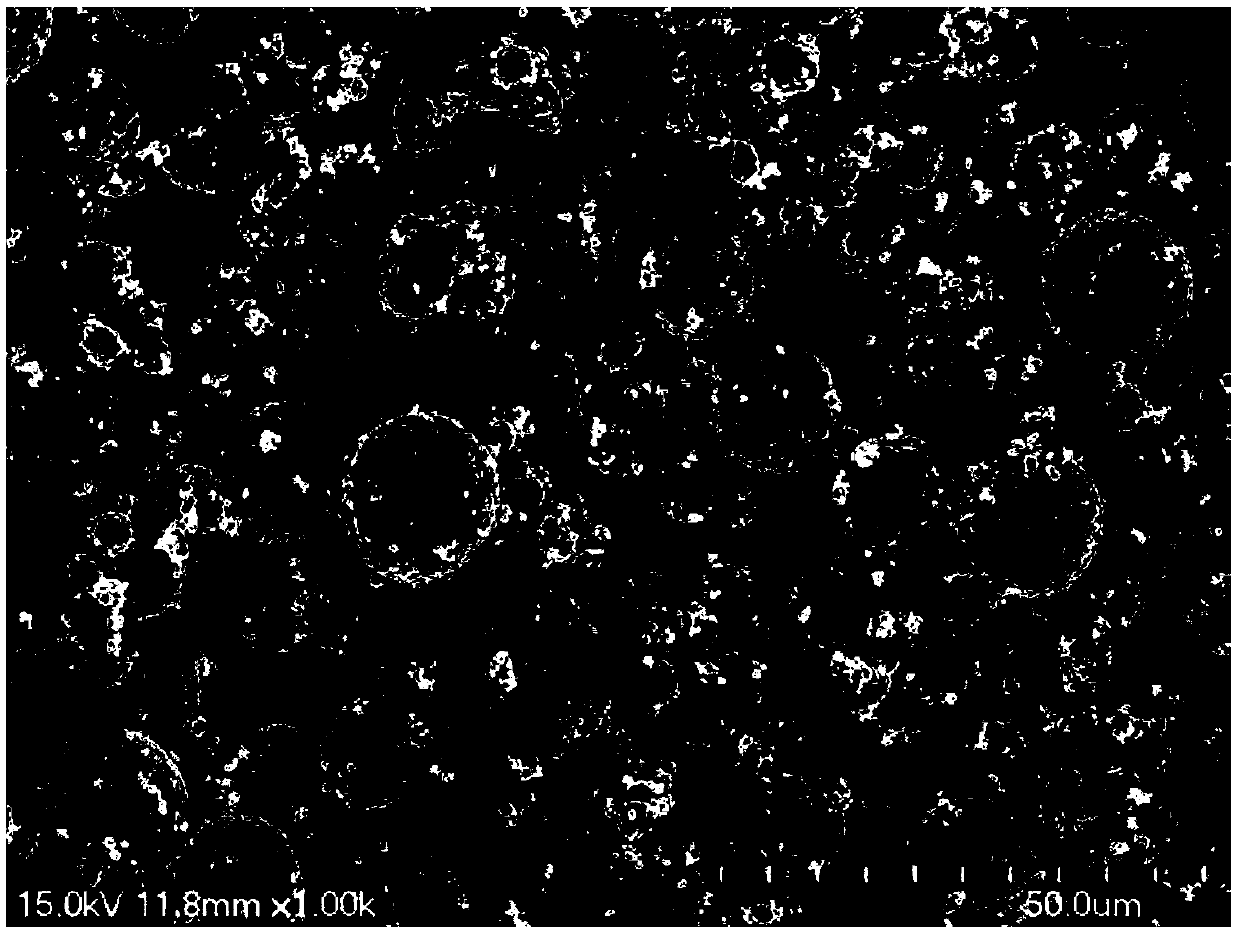

[0028] figure 1 It is a diagram of the sintering reaction process of the high-nickel ternary material; figure 2 is the fine powder EMD particle size distribution diagram; image 3 SEM image of finished product;

[0029] Figure 4 is a cyclic comparison chart. refer to Figure 1~4 , the present invention has the following advantages: the present invention can reduce the pH value of the material and the residual alkali on the surface. The PH value of the material can be reduced from the original 12 or more to 11.5-11.8; since the PH value of the coating agent EMD parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com