Electronic silver paste for annular varistor and preparation method thereof

A piezoresistor and silver paste technology, which is applied in the direction of piezoresistor, cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problem of high price of silver paste products, increase of production cost of manufacturers, Reduce the fluidity of slurry and other problems, achieve the effect of improving market competitiveness and profit margins, preventing the phenomenon of soldering silver corrosion, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment, an electronic silver paste for ring varistors, the electronic silver paste is composed of the following components: ultrafine silver powder 40%, spherical silver powder 30%, organic carrier 15%, metal oxide 10%, Thinner 5%. among them

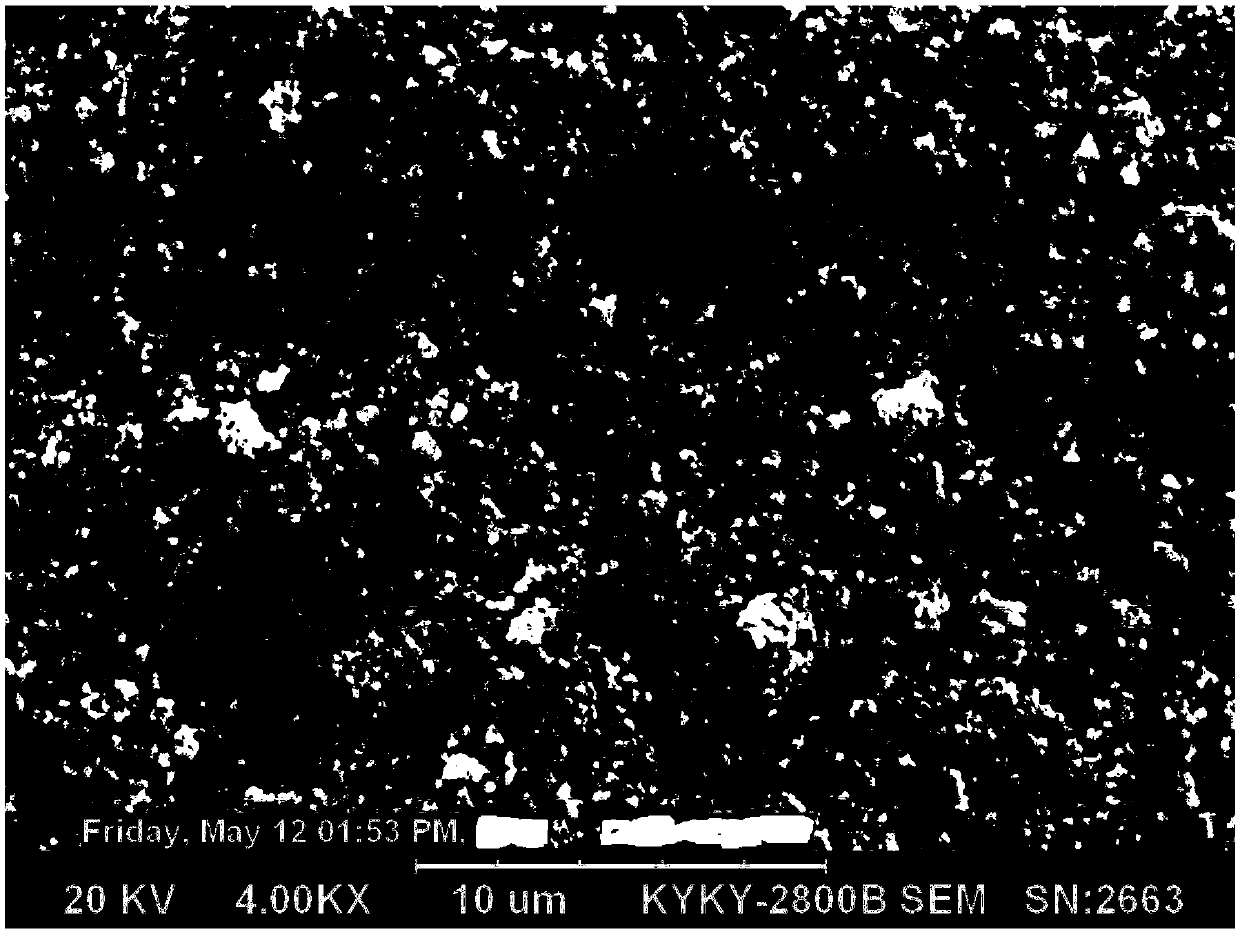

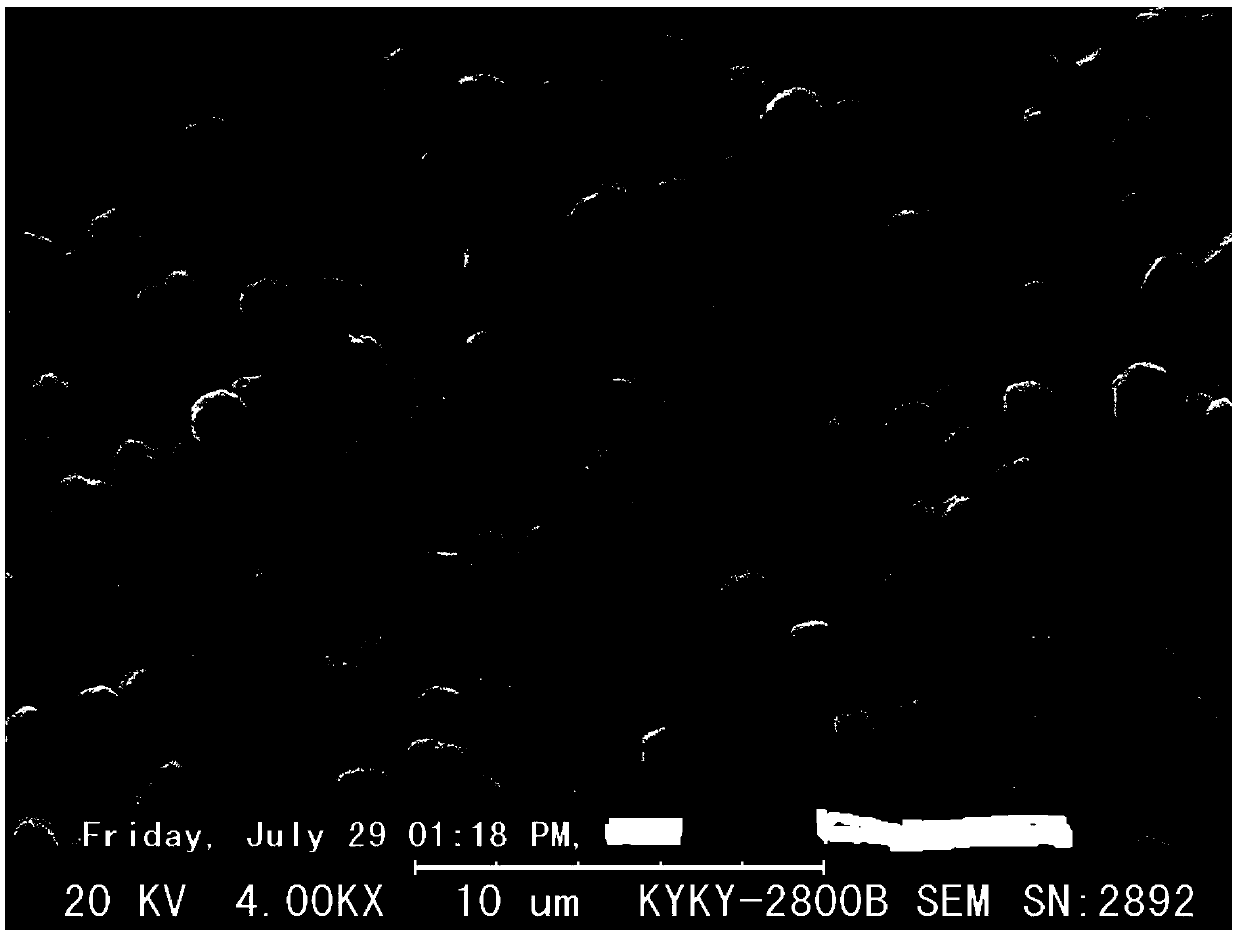

[0034] The specific surface area of the superfine silver powder is 5.0m 2 / g, the particle size is 1.0μm, and the tap density is 3.0g / mL; the specific surface area of the spherical silver powder is 0.30m 2 / g, the particle size is 2.0 μm, and the tap density is 7.0 g / mL. Such as figure 2 As shown, figure 2 Is the electron micrograph of the spherical silver powder used in the present invention;

[0035] The organic carrier is composed of the following components by weight percentage: ethyl cellulose 10%, diethylene glycol ethyl ether 30%, diethylene glycol butyl ether acetate 20%, terpineol 15%, and leveling agent 10% , Butyl Carbitol 15%.

[0036] The metal oxide is composed of the following components in weight per...

Embodiment 2

[0044] In this embodiment, an electronic silver paste for ring varistors is composed of the following components: 50% ultrafine silver powder, 25% spherical silver powder, 12% organic carrier, 7% metal oxide, Thinner 6%. among them

[0045] The specific surface area of the superfine silver powder is 8.0m 2 / g, the particle size is 0.8μm, the tap density is 2.0g / mL; the specific surface area of the spherical silver powder is 0.40m 2 / g, particle size is 2.5μm, tap density is 6.0g / mL

[0046] The organic carrier is composed of the following components by weight percentage: 15% ethyl cellulose, 20% diethylene glycol ether, 15% diethylene glycol butyl ether acetate, 12% terpineol, and 8% leveling agent , Butyl Carbitol 30%.

[0047] The metal oxide is composed of the following components by weight percentage: zinc oxide 20%, bismuth oxide 40%, aluminum oxide 15%, iron oxide 10%, and nickel oxide 15%.

[0048] The diluent is composed of the following components in weight percentage, ...

Embodiment 3

[0055] In this embodiment, an electronic silver paste for ring varistors is composed of the following components: ultrafine silver powder 45%, spherical silver powder 30%, organic carrier 10%, metal oxide 8%, Thinner 7%. among them

[0056] The specific surface area of the superfine silver powder is 8.0m 2 / g, the particle size is 1.5μm, the tap density is 2.8g / mL; the specific surface area of the spherical silver powder is 0.45m 2 / g, particle size is 2.3μm, tap density is 7.0g / mL

[0057] The organic carrier is composed of the following components in weight percentage: ethyl cellulose 12%, diethylene glycol ethyl ether 18%, diethylene glycol butyl ether acetate 18%, terpineol 12%, leveling agent 5% , Butyl Carbitol 35%.

[0058] The metal oxide is composed of the following components in weight percentage: 25% zinc oxide, 45% bismuth oxide, 12% aluminum oxide, 8% iron oxide, and 10% nickel oxide.

[0059] Preferably, the diluent is composed of the following components in weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com