Integrated type laser-cladding coaxial powder feeding spray nozzle

A technology of laser cladding and coaxial powder feeding, applied in metal material coating process, coating and other directions, can solve the problem of inconsistent heating and deformation of split nozzles, achieve timely and rapid water cooling, avoid waste, and avoid the effect of sticking powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

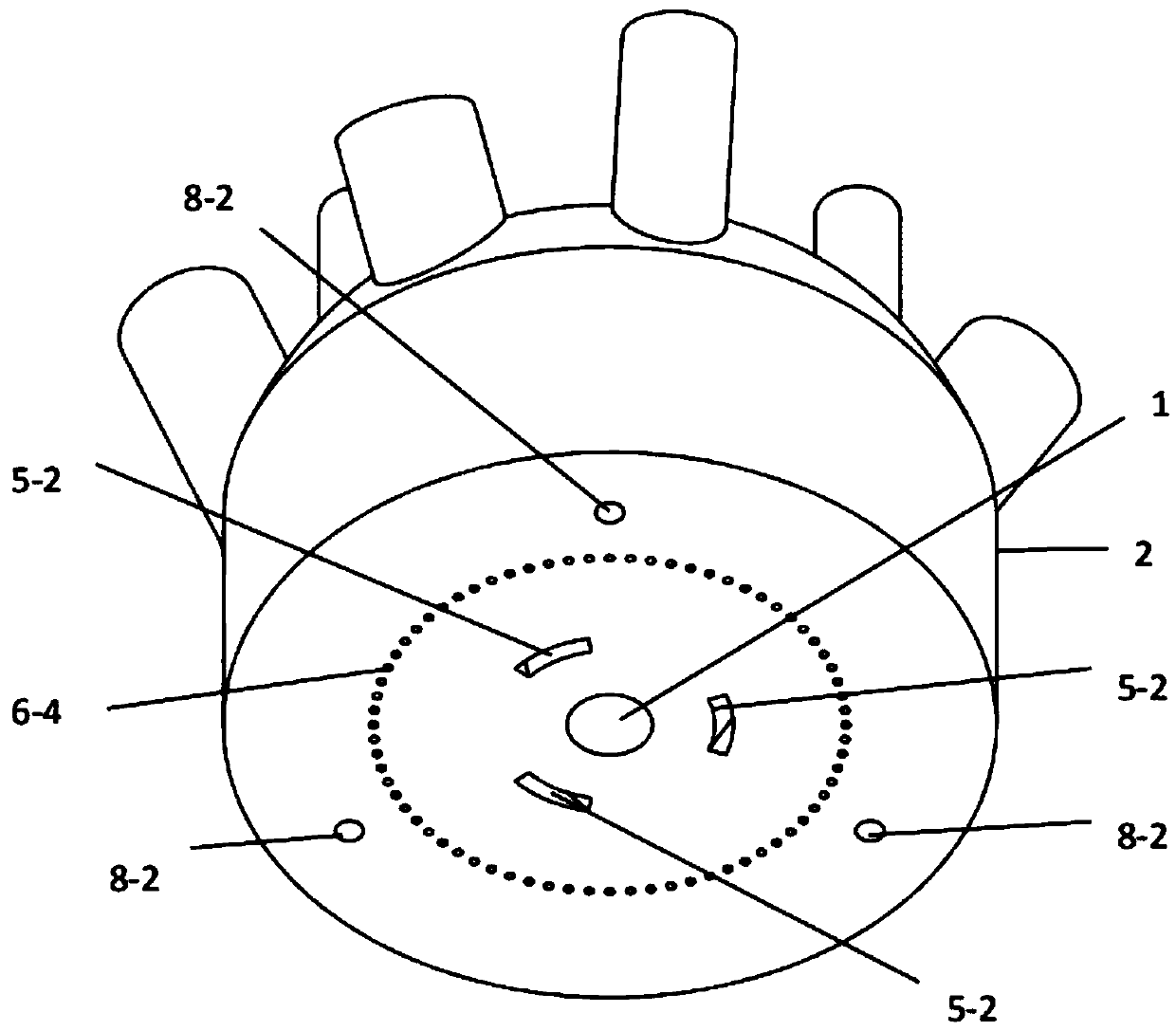

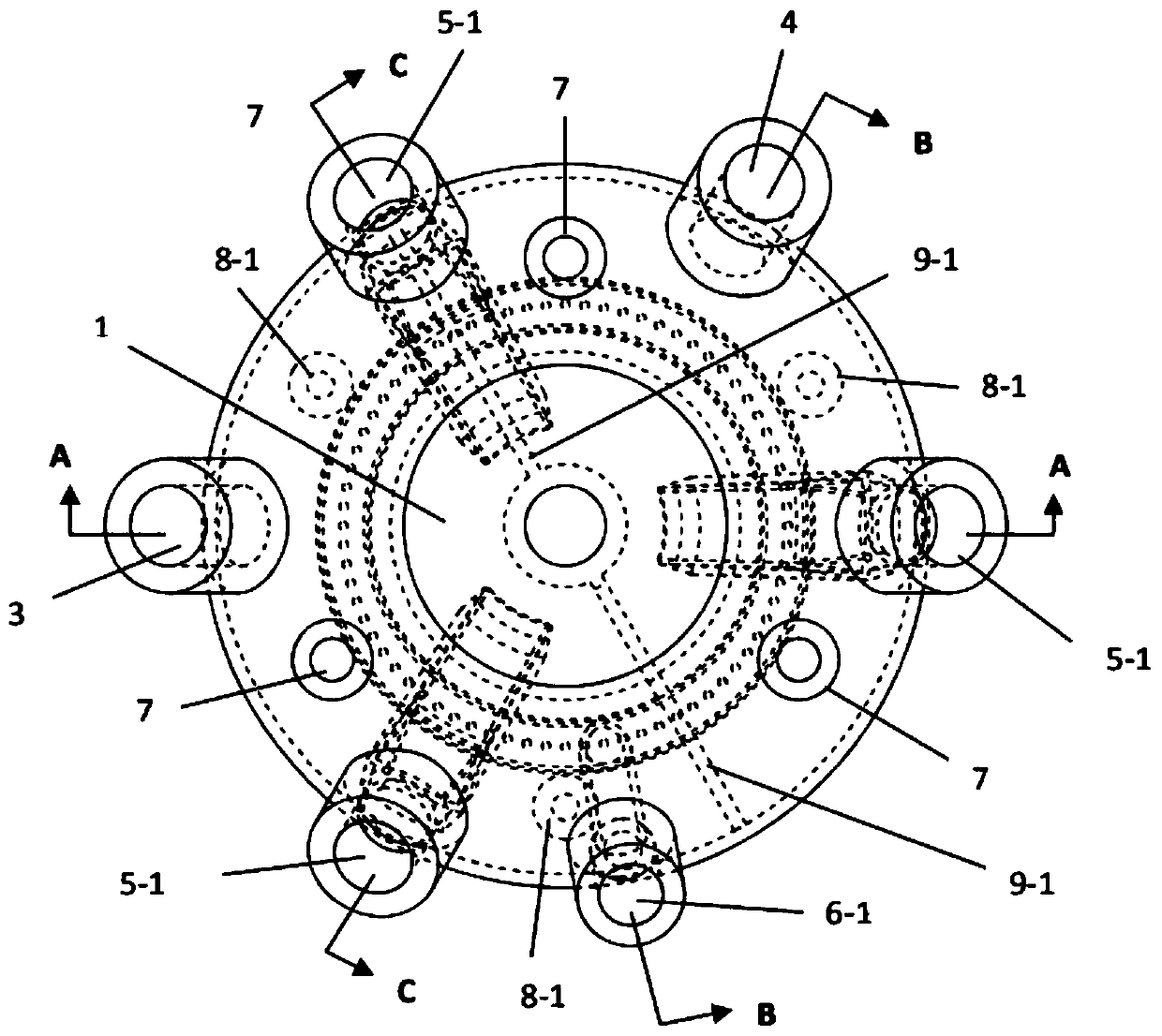

[0035] Such as Figure 1-10, an integrated laser cladding coaxial powder feeding nozzle, including an integrally formed main body, the main body has a top wall, an outer wall 2 and a bottom wall, a through hole is opened in the center of the bottom wall, an opening is formed in the center of the top wall, and the edge of the opening is downward Extending to meet the side wall of the through hole to form a laser beam channel 1, the top wall, the outer wall 2, the bottom wall and the side wall of the laser beam channel 1 are enclosed to form a cavity,

[0036] Several powder passages 5-3 are pierced in the cavity, and the part of the powder passage 5-3 exposed outside the main body is provided with a powder inlet 5-1, and the bottom wall is provided with a powder outlet 5-2 communicating with the powder passage 5-3;

[0037] The cavity is also provided with a gas channel 6-2 for filling inert gas. The gas channel 6-2 is provided with a gas inlet 6-1 outside the main body, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com