Drying cabinet

A drying cabinet and cabinet body technology, which is applied in drying chambers/containers, partial agitation dryers, dryers for static materials, etc., can solve the problems of wasting time, damage to glass instruments, and slow drying speed, and achieve simple production, Novel structure, saving drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

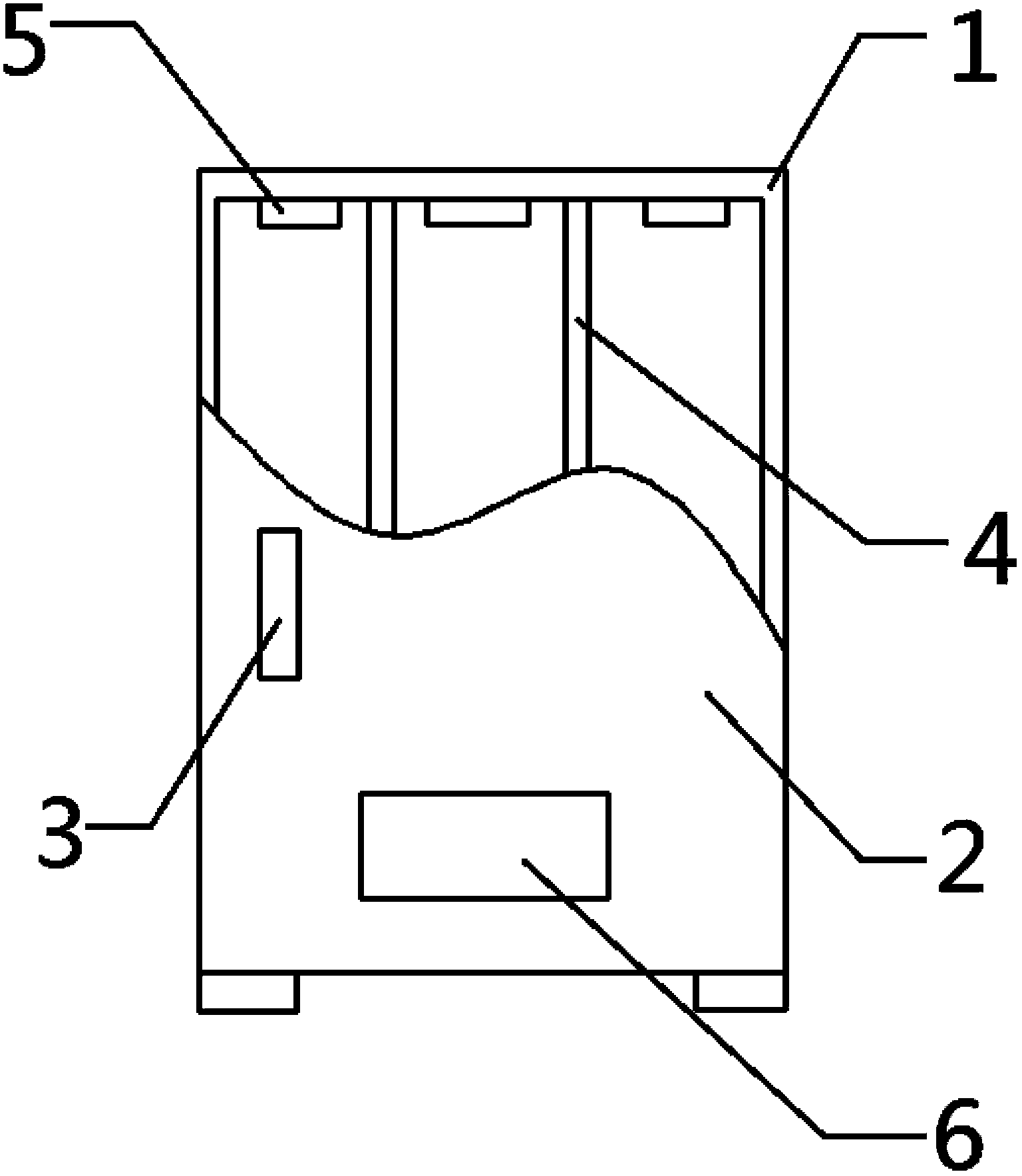

[0009] A kind of drying cabinet as shown in the figure includes a cabinet body 1 and a cabinet door 2, and the interior of the cabinet body 1 is provided with a plurality of heat insulating partitions 4 from the bottom of the cabinet to the top of the cabinet; Each independent area is provided with an infrared temperature controller 5; the lower end of the cabinet door 2 surface is provided with a control panel 6, and the control panel 6 controls each infrared temperature controller 5; one side of the cabinet door 2 is provided with a switch handle 3 .

[0010] The working process of this example: when using this equipment for drying, open the cabinet door 2 through the switch handle 3, and place the glass instruments with the same temperature resistance in the same independent drying space separated by the heat insulation partiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com