Preparation method and equipment for novel biomagnetic ceramsite filling for water treatment

A technology of water treatment and ceramsite, which is applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc. It can solve the problems that cannot meet the sewage discharge standards, etc., and achieve good loading effect and biofilm microorganisms Agglomeration promotion and the effect of low breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

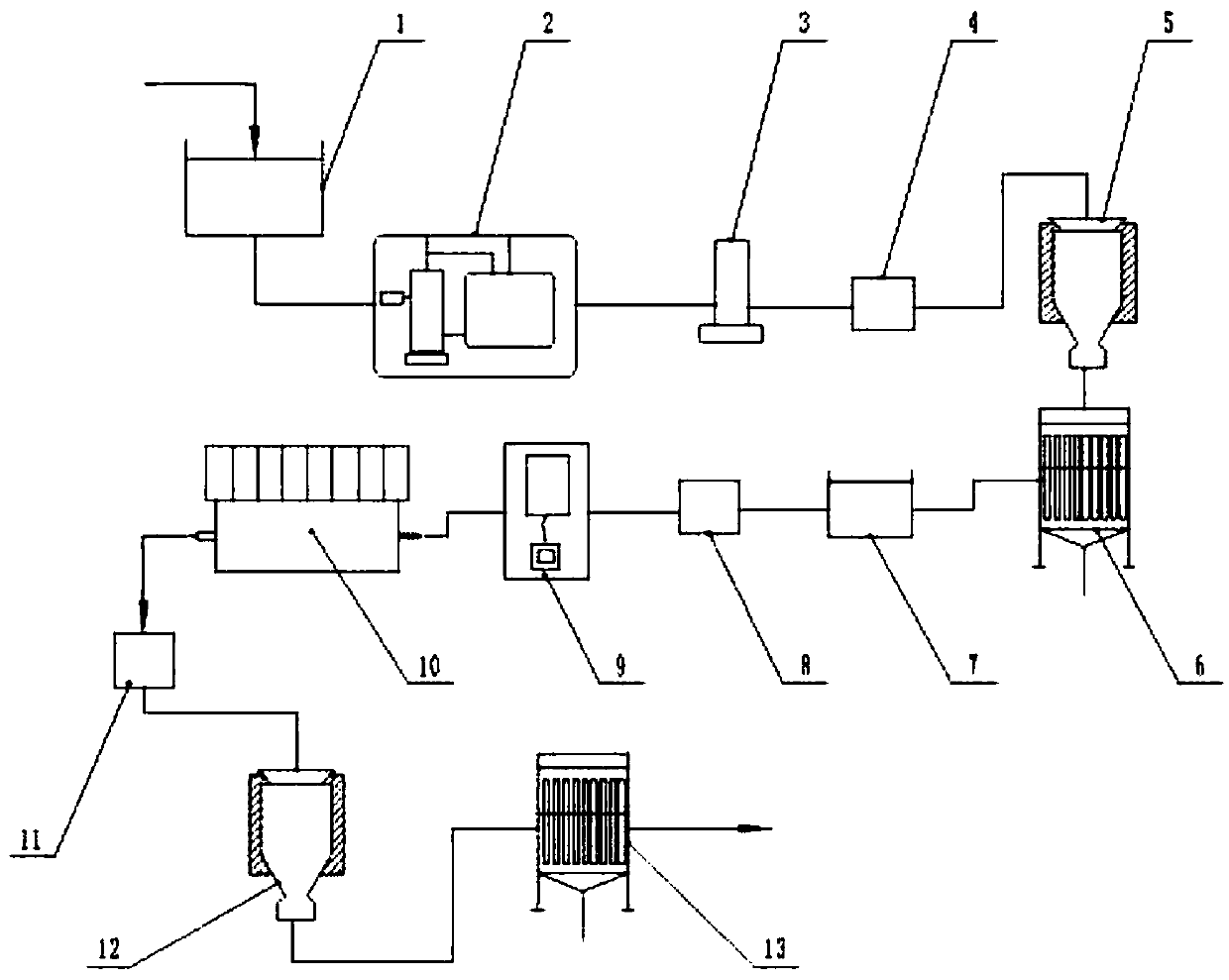

[0067] The preparation of novel biomagnetic ceramsite filler for water treatment comprises the following steps:

[0068] S1: Magnetic powder activation: use ferric oxide powder as magnetic powder, soak and activate in glutaraldehyde to obtain activated magnetic powder;

[0069] S2: Ingredients: Mix ceramsite composed of bauxite and clay, activated magnetic powder, borax, and titanium dioxide according to the following ratio: 25 parts of bauxite, 10 parts of clay, 20 parts of magnetic powder, 1 part of borax, and 1 part of titanium dioxide , and stir evenly to obtain the mixed material A;

[0070] S3: Granulation and drying: Send the mixed material A in S2 into the magnetic microbubble stirring and mixing device, and mix it with water according to the weight ratio of 1:0.45 to obtain the mixed material B, and then mix the mixed material B Put it into a granulator to prepare a spherical mixture material with a diameter of 6mm, then put the spherical mixture material into a dryi...

Embodiment 2

[0077] The difference from Example 1 is:

[0078] The magnetic powder in S2 is composed of ferroferric oxide and ferric oxide mixed in an equal weight ratio;

[0079] The composition of the mixed material A in S2 is: 22 parts of bauxite, 18 parts of sea mud clay, 30 parts of magnetic powder, 3 parts of borax, and 2 parts of titanium dioxide;

[0080] The mixed material B in S3 is granulated into a 7mm spherical mixed material, and the drying time is 1.5h;

Embodiment 3

[0082] The difference from Example 1 is:

[0083] The magnetic powder in S2 is composed of ferric oxide and ferric oxide in a weight ratio of 3:1;

[0084] The composition of the mixed material A in S2 is: 25 parts of clay, 20 parts of mudstone, 40 parts of magnetic powder, 5 parts of borax, and 3 parts of titanium dioxide;

[0085] The mixed material B in S3 is granulated into a 8mm spherical mixed material, and the drying time is 2h;

[0086] The drying time in S8 is 2h.

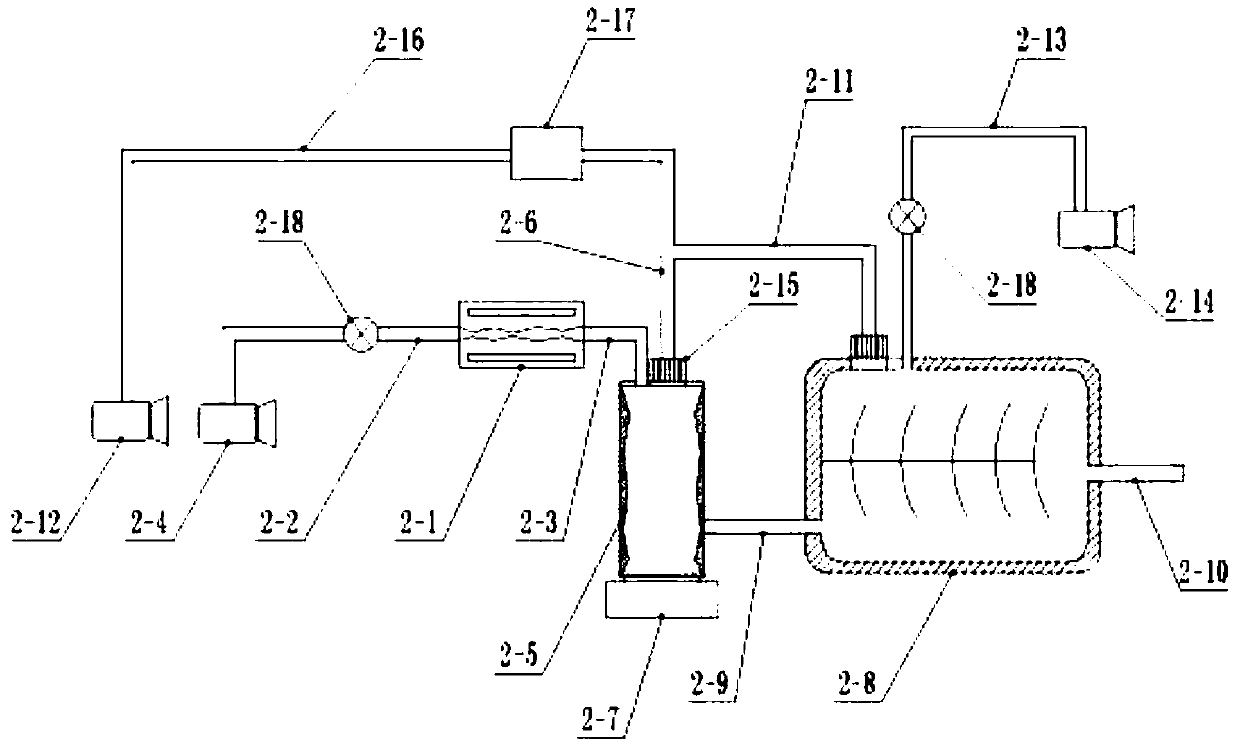

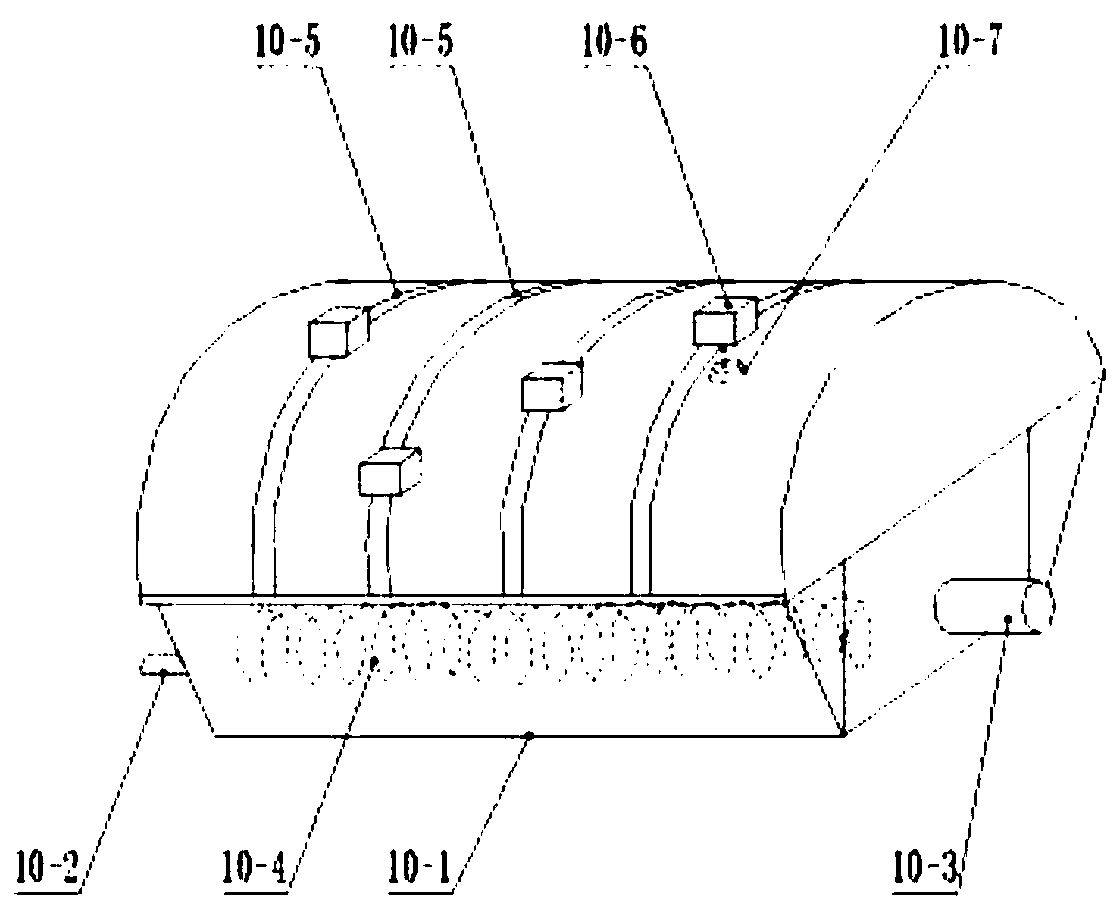

[0087] The magnetic microbubble stirring and mixing device used in the above-mentioned embodiment 1-3 comprises:

[0088] The variable cross-section water molecule destruction chamber 2-1 is provided with a passage for water to pass through and a magnet outside the passage. The cross-section of the passage is a variable cross-section, and the magnet can magnetize water. One end of the destruction chamber 2-1 is provided with a water inlet pipe 2-2, and one end is provided with a water outlet pipe 2-3, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com