Tantalum-doped cesium tungsten bronze and preparation method and application thereof

A technology of cesium tungsten bronze and tungsten acid is applied in the field of tantalum-doped cesium tungsten bronze and its preparation, which can solve the problems of low visible light transmittance, limited shielding of tungsten bronze against near-infrared light, etc., and achieves the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Weigh 1.628g of sodium tungstate and ultrasonically dissolve it in deionized water to make a 0.3mol / L sodium tungstate aqueous solution, weigh 0.0179g of tantalum chloride and dissolve it in an ethanol solution to make a 0.1mol / L tantalum chloride ethanol solution. After the above two are mixed, add 35mL of 0.5mol / L ammonium sulfate aqueous solution and mix evenly to obtain a mixed solution; add 7% nitric acid solution to the above mixed solution, control its pH0.33 Ta 0.01 W 0.99 o 3 Tantalum doped cesium tungsten bronze nanopowder.

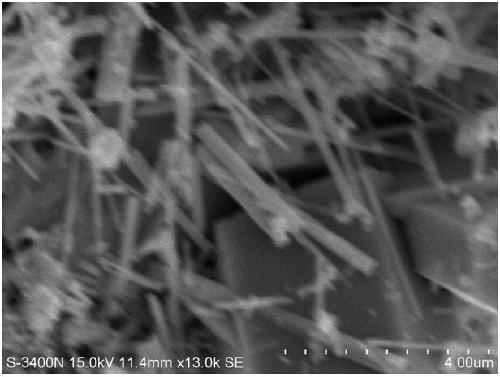

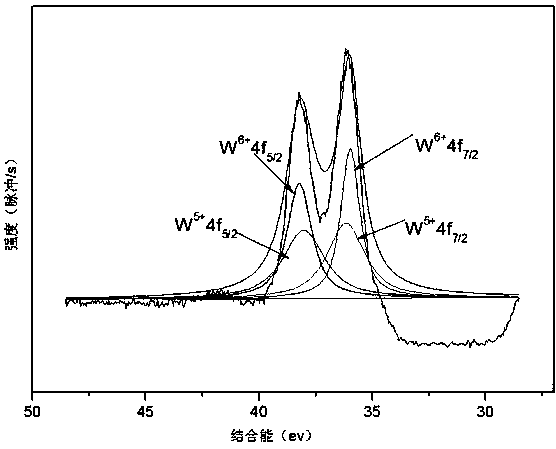

[0046] The obtained tantalum-doped cesium tungsten bronze nanopowders were characterized by X-ray diffractometer, scanning electron microscope, energy dispersive spectrometer, X-ray photoelectron spectrometer and transmission electron microscope.

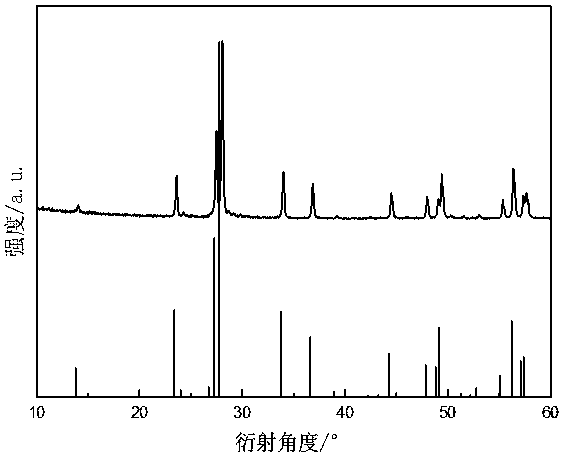

[0047] figure 1 The tantalum-doped cesium tungsten bronze nanopowder Cs obtained for this implementation 0.33 Ta 0.01 W 0.99 o 3 The XRD diffraction spectrum figure, from which it can be...

Embodiment 2

[0049] Weigh 1.616g of sodium tungstate and ultrasonically dissolve it in deionized water to make a 0.3mol / L sodium tungstate aqueous solution, weigh 0.0358g of tantalum chloride and dissolve it in an ethanol solution to make a 0.1mol / L tantalum chloride ethanol solution. After the above two are mixed, add 35mL of 0.5mol / L ammonium sulfate aqueous solution and mix evenly to obtain a mixed solution; add 7% nitric acid solution to the above mixed solution, control its pH<2, and make the above solution form a tungstic acid sol; Dissolve 0.278g of cesium chloride in deionized water and stir thoroughly, mix well with tungstic acid sol, add reducing agent ethylene glycol and water mixed solution, stir in 80°C water bath for 1 hour, then put it into the reaction of polytetrafluoroethylene lining Conduct hydrothermal reaction at 200°C for 48 hours in a kettle, wash with water, wash with alcohol and dry, and then calcinate at 600°C for 2 hours under an argon atmosphere to obtain tantalu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com