Cerium dioxide chlorination device

A ceria and chlorination device technology, applied in rare earth metal chlorides, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of unreported recyclable devices, increased waste disposal, and complicated equipment, etc. Good development and application prospects, high utilization rate, and the effect of less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

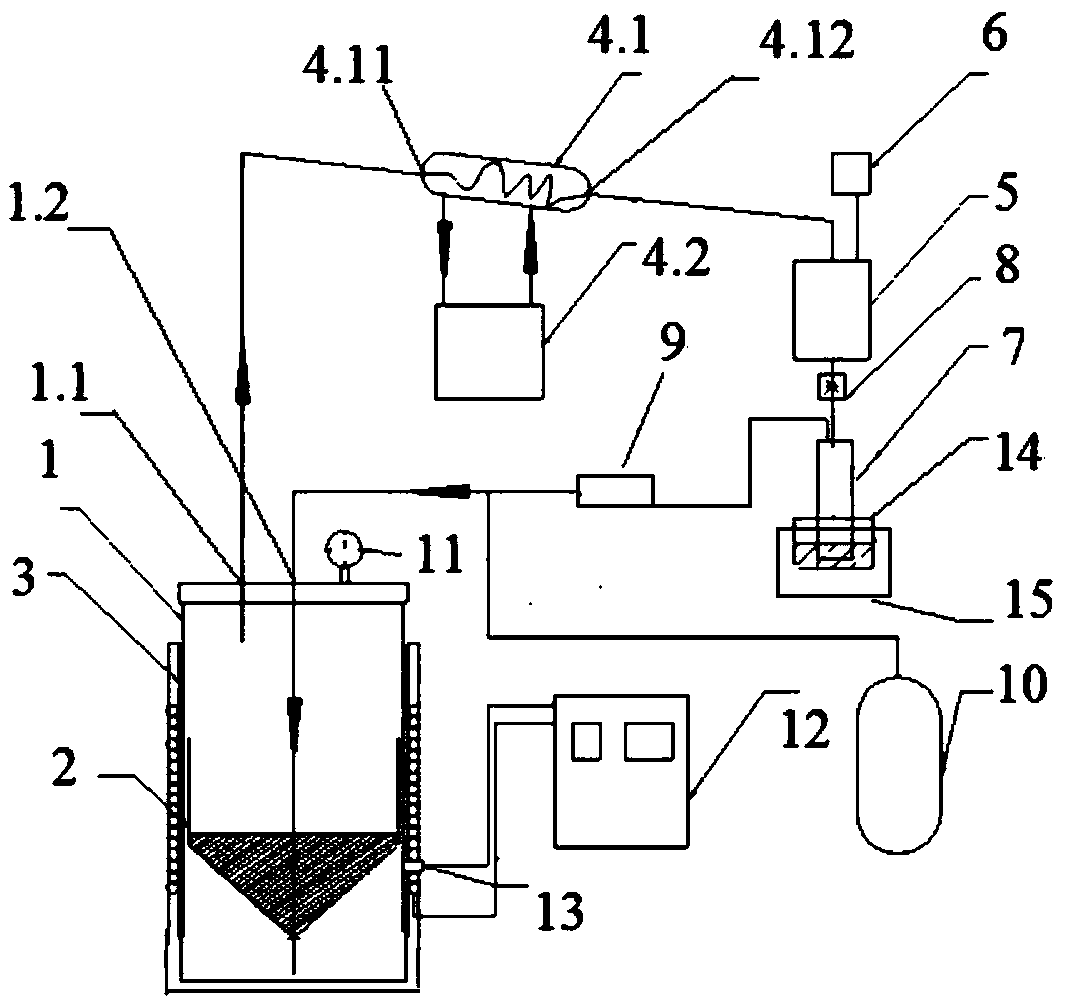

[0030] Such as figure 1 As shown, a kind of ceria chlorination device that the embodiment of the present invention provides, comprises:

[0031] Reactor (reactor): Reactor 1 includes a reactor body and a lid, wherein the lid has a liquid inlet 1.1 and an air guide hole 1.2. The mouth of the draft tube of the liquid port is close to the bottom of the reaction kettle. Reactor 1 contains CCl inside 4 Liquid and CCl 4 The ceria solid loading device above the liquid, the ceria solid loading device is a conical crucible 2;

[0032] A heating unit, which selects a conventional electric resistance furnace 3, surrounds the outer surface of the reactor 1, and heats the reactor 1;

[0033] The condensing unit 4 includes a connected condenser 4.1 and a cooling circulating water machine 4.2. The cooling water enters from the lower hole of the condenser 4.1 and flows out from the upper hole. The condenser 4.1 is respectively provided with a first gas inlet 4.11 and a first gas-liquid o...

Embodiment 2

[0044] Such as figure 2 As shown, this embodiment is similar to Embodiment 1, and a temperature control unit is provided on the basis of Embodiment 1, including a temperature controller 12 and a thermocouple 13; Monitor the real-time temperature in Reactor 1. In addition, the above CCl 4 The liquid collection unit can also be connected with CCl through the one-way valve 14 4 The raw material supply unit (raw material tank 15) is communicated.

[0045] When the device of this embodiment is in use, after adding cerium dioxide into the conical crucible 2, each part of the chlorination device is figure 2 Install the connections inside the glove box. Liquid CCl in Reactor 1 4 After the resistance furnace 3 is heated to 500° C., it reacts with the ceria in the conical crucible 2 in the reaction kettle 1 . Gaseous reaction products and some CCl 4 Into the gas duct of reactor 1, part of the gaseous CCl in the gas duct 4 After cooling in the pipeline, it becomes liquid and pa...

Embodiment 3

[0048] Such as figure 2 As shown, the present embodiment is similar to the embodiment 1, and the parameters are changed on the basis of the embodiment 1, specifically: the temperature selected for the reaction in the reactor 1 during the chlorination reaction is 600°C; the centrifugal pump 9 is pumped into CCl 4 The flow rate of the cooling water machine is controlled at 10mL / min; 4.2 The temperature of the cooling water in the cooling circulating water machine is 25°C. CCl 4 The utilization rate is extremely high, the yield of the chlorination product is 98.99%, and the utilization rate of carbon tetrachloride is 92.87% through analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com