Three-degree-of-freedom electrohydraulic-mechanism numerically-controlled bucket wheel machine

A degree of freedom and mechanism-based technology, applied in the field of three-degree-of-freedom electro-hydraulic mechanical numerical control bucket wheel machine, can solve the problems of high maintenance and use costs, poor flexibility, rigid damage of fuselage structural parts, etc., to save maintenance and The cost of use, the effect of overcoming poor reliability and large working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

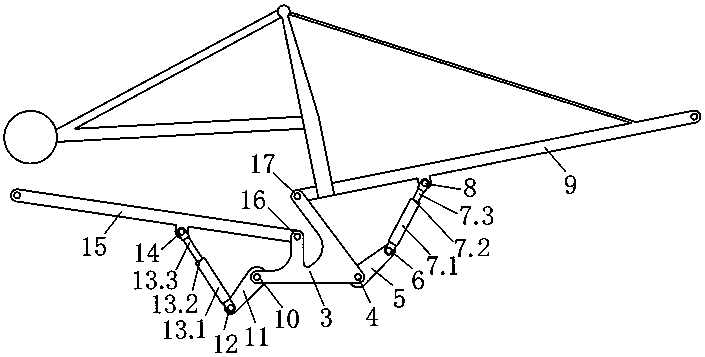

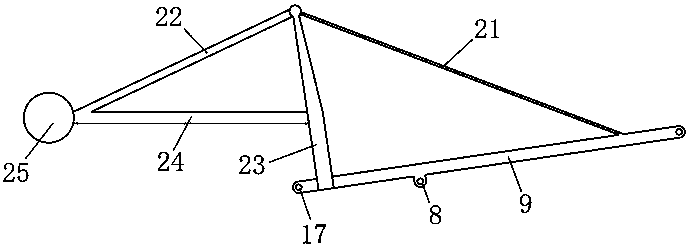

[0030] control figure 1 , figure 2 , image 3 , a three-degree-of-freedom electro-hydraulic mechanism type numerical control bucket wheel machine, comprising a traveling mechanism 1, a frame 3, a front cantilever lifting mechanism, a bucket wheel mechanism 21, and a conveying system; the frame 3 is connected to the traveling mechanism through the first rotating pair 2 1 connection, the first rotating pair 2 is the active pair, under the drive control of the electric transmission system, the frame 3 can rotate relative to the running mechanism; the front cantilever lifting mechanism is a two-degree-of-freedom full-rotating pair planar five-bar mechanism , including the front cantilever drive branch chain, the first active rod 11, the frame 3, the front cantilever 9, the front cantilever drive branch chain includes the second active rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com