Three-freedom parallel mechanism driven by flexible rope

A cable-driven, degree-of-freedom technology, applied to manipulators, manufacturing tools, etc., can solve problems such as limited working space and range of motion, large component mass and moment of inertia, and difficulty in achieving high-speed motion, reducing quality and power consumption Low, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

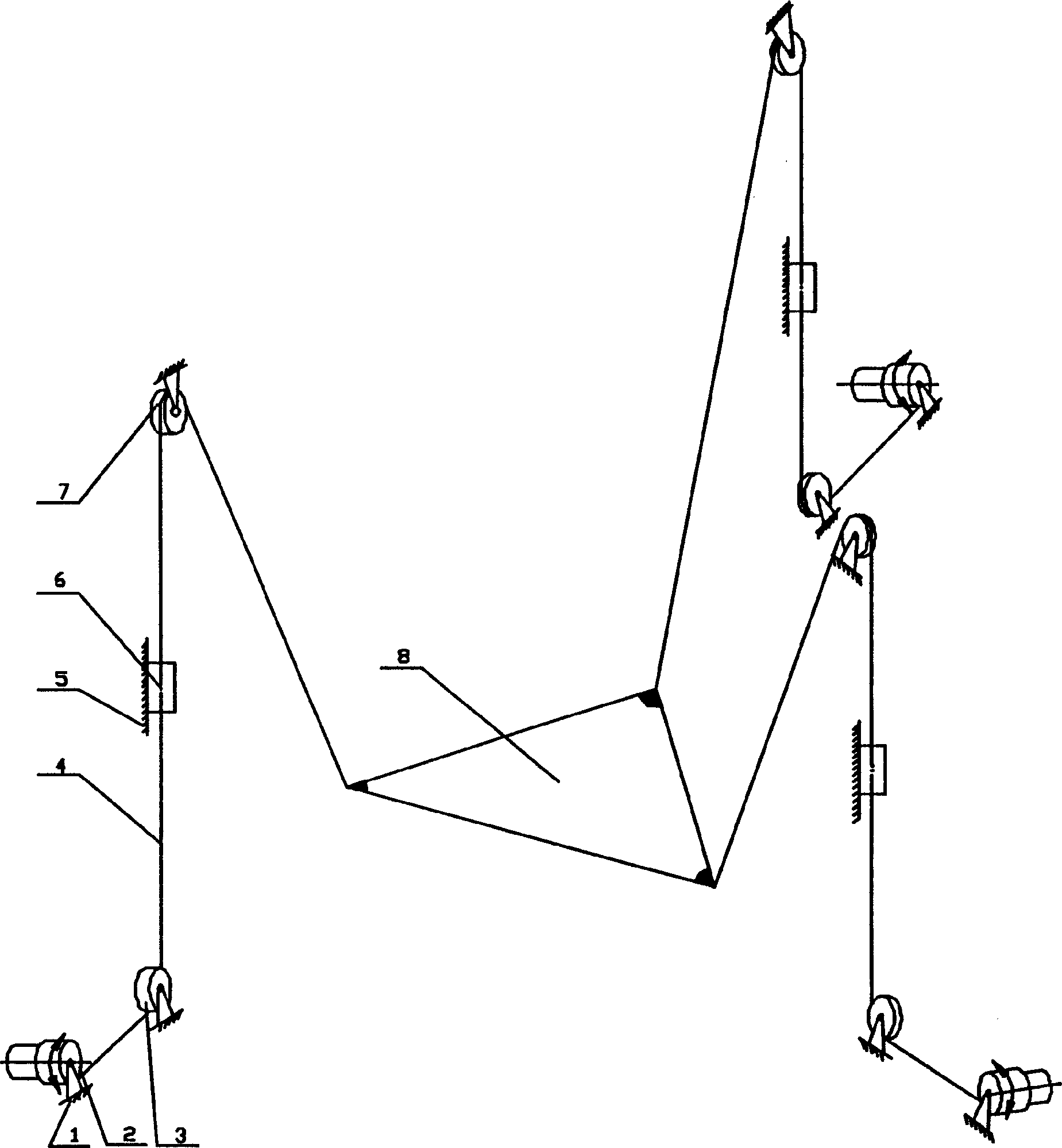

[0016] Such as figure 1 As shown, the parallel mechanism of the present invention is composed of three groups of drive units and a motion platform 8, wherein: each drive unit includes a base 1, a reel 2 installed with a motor, a column 5, a counterweight 6, an upper, Fixed pulleys 7, 3 and steel wire rope 4 are placed below, and the column 5 is vertically fixed on the machine base 1. There is a fixed pulley on the top and bottom respectively, and the steel wire rope 4 is wound on the reel 2 with a spiral groove on it. When the reel 2. When rotating in the forward and reverse directions, the steel wire rope 4 can be rolled in or released; the steel wire rope 4 drawn from the reel 2 is connected to the lower part of the counterweight 6 through the lower fixed pulley 3, and the steel wire 4 drawn from the upper part of the counterweight 6 bypasses The upper fixed pulley 7 is connected to the motion platform 8; the wire ropes 4 drawn from the three sets of drive units are all conn...

Embodiment 2

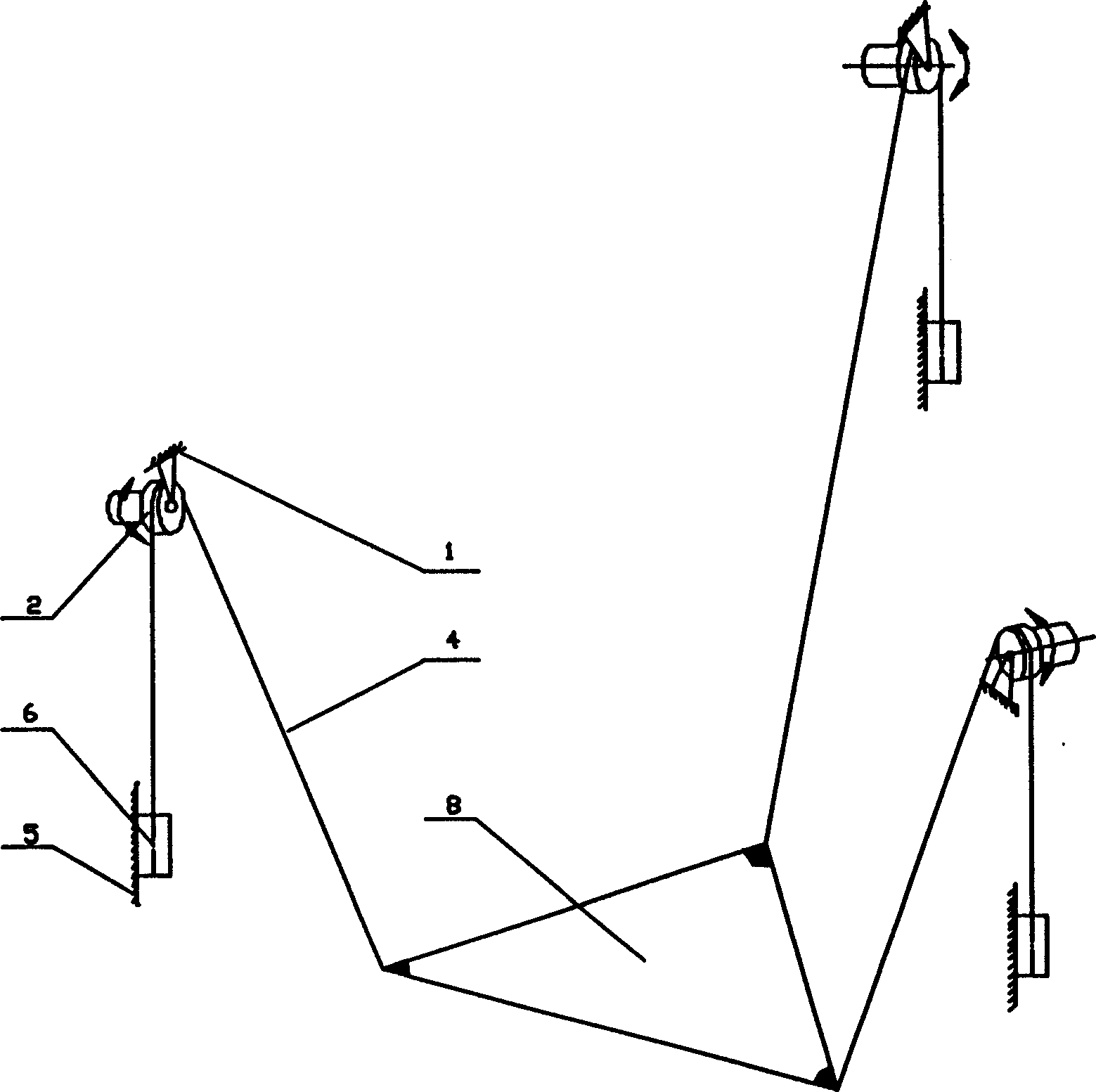

[0021] Such as figure 2 As shown, the difference between the present invention and Embodiment 1 is: the reel 2 installed with the motor is fixed at a high place, six fixed pulleys are omitted, and five steel wire ropes 4 are wound side by side on the reel 2, and one end of the steel wire rope 4 is It is connected to the motion platform 8, and the other end is connected to the counterweight 6. The friction between the reel 2 and the wire rope 4 is used to transmit motion and power. The driving principle is similar to that of an elevator; three sets of drive units are used to adjust the length of the three wire ropes. The motion platform 8 can realize pitching, rolling and moving along the vertical direction.

[0022] The motion platform 8 in this embodiment forms a triangle and is an equilateral triangle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com