Waterproof anti-ultraviolet fabric

An anti-ultraviolet and anti-ultraviolet agent technology, which is applied in the field of fabrics, can solve the problems of single characteristics, reducing the comfort of wearing clothes, waterproof and anti-ultraviolet, and achieve good waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

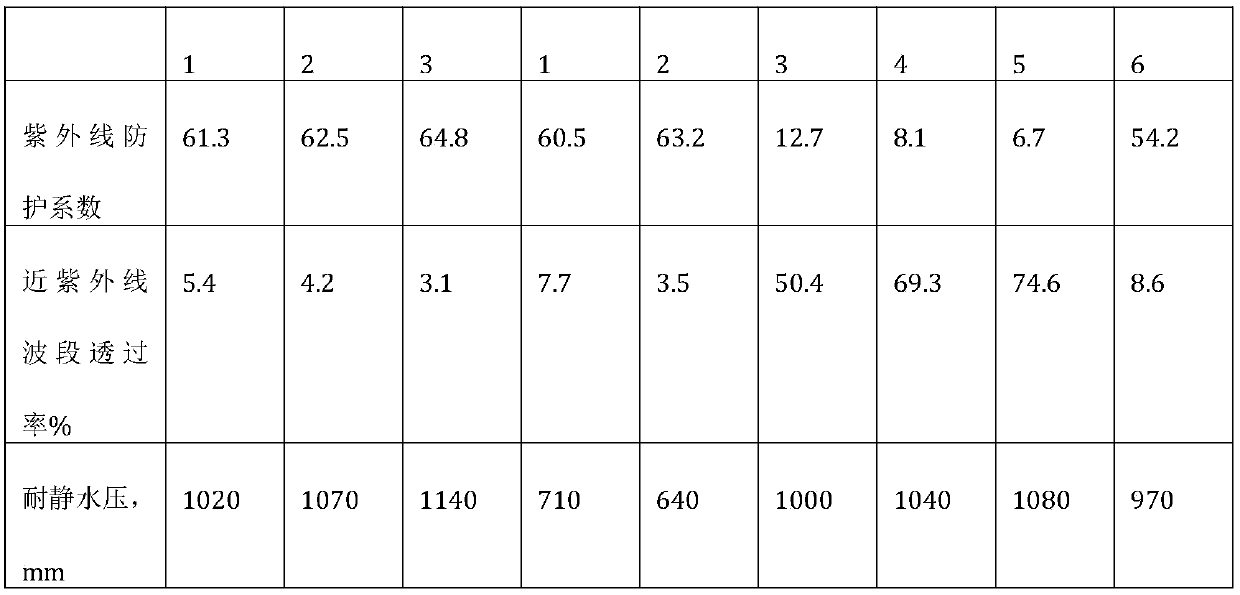

Embodiment 1

[0046] A waterproof and anti-ultraviolet fabric. The fabric includes a waterproof layer, an anti-ultraviolet layer and an absorption layer. The anti-ultraviolet layer is wrapped by the waterproof layer and the absorption layer;

[0047] 50 parts of polyamide fiber;

[0048] 20 parts of waterproof polypropylene fiber.

[0049] The waterproof polypropylene fiber contains 6 wt% of a waterproofing agent; the waterproofing agent includes 20 parts of hydroxypropyl methylcellulose-hydroxyethyl cellulose-cellulose ether and 12 parts of polyoxyethylene ether trisiloxane.

[0050] The anti-ultraviolet layer includes the following raw materials in parts by weight:

[0051] 30 parts of polyacrylonitrile fiber;

[0052] 20 parts of polylactic acid fiber;

[0053] 4 parts mint fiber;

[0054] The peppermint fiber also includes 3wt% anti-ultraviolet agent; the anti-ultraviolet agent includes 10 parts Ti2AlC, 3 parts benzophenone, 2 parts hexamethylphosphoric triamide and 2 parts sulfated castor oil.

[00...

Embodiment 2

[0061] A waterproof and anti-ultraviolet fabric. The fabric includes a waterproof layer, an anti-ultraviolet layer and an absorption layer. The anti-ultraviolet layer is wrapped by the waterproof layer and the absorption layer;

[0062] 54 parts of polyamide fiber;

[0063] 22 parts of waterproof polypropylene fiber.

[0064] The waterproof polypropylene fiber contains 7wt% of the waterproofing agent; the waterproofing agent includes 22 parts of hydroxypropyl methylcellulose-hydroxyethyl cellulose-cellulose ether and 13 parts of polyoxyethylene ether trisiloxane.

[0065] The anti-ultraviolet layer includes the following raw materials in parts by weight:

[0066] 32 parts of polyacrylonitrile fiber;

[0067] 24 parts of polylactic acid fiber;

[0068] 5 parts mint fiber;

[0069] The peppermint fiber also includes 5wt% anti-ultraviolet agent; the anti-ultraviolet agent includes 11 parts Ti2AlC, 3 to 5 parts benzophenone, 3 parts hexamethylphosphoric triamide and 3 parts sulfated castor oil...

Embodiment 3

[0076] A waterproof and anti-ultraviolet fabric. The fabric includes a waterproof layer, an anti-ultraviolet layer and an absorption layer. The anti-ultraviolet layer is wrapped by the waterproof layer and the absorption layer;

[0077] 60 parts of polyamide fiber;

[0078] 30 parts of waterproof polypropylene fiber.

[0079] The waterproof polypropylene fiber contains 8wt% of a waterproofing agent; the waterproofing agent includes 25 parts of hydroxypropyl methylcellulose-hydroxyethyl cellulose-cellulose ether and 14 parts of polyoxyethylene ether trisiloxane.

[0080] The anti-ultraviolet layer includes the following raw materials in parts by weight:

[0081] 34 parts of polyacrylonitrile fiber;

[0082] 25 parts of polylactic acid fiber;

[0083] 6 servings of peppermint fiber.

[0084] The peppermint fiber also includes 7wt% anti-ultraviolet agent; the anti-ultraviolet agent includes 12 parts Ti2AlC, 5 parts benzophenone, 4 parts hexamethylphosphoric triamide and 4 parts sulfated casto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com