Self-compacting freeze-thaw resistant concrete and preparation method thereof

A freeze-thaw resistance, concrete technology, applied in the field of concrete, can solve the problems of cracks and fine lines in concrete, poor freeze-thaw effect, etc., to prevent segregation and bleeding problems, improve freeze-thaw resistance performance, improve slurry - Effect of solid ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

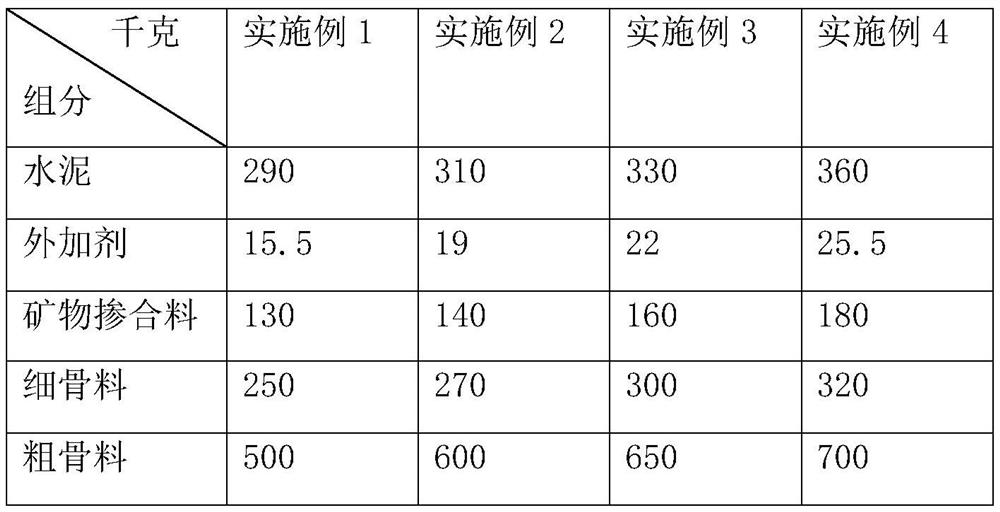

Examples

preparation example 1

[0045] Preparation Example 1: (1) According to the proportioning in Table 1, 50 kilograms of water, 10 kilograms of polyvinyl alcohol, 5 kilograms of sodium formate, 5 kilograms of potassium thiocyanate, and 5 kilograms of sodium thiosulfate were added to the reactor successively, and the The temperature of the reactor was controlled at 95°C, and stirred for 60 minutes; (2) the temperature was lowered to 60°C, and 10 kg of ethylene glycol, 5 kg of potassium acetate and 10 kg of sodium nitrate were added in sequence, and stirred for 100 minutes;

[0046] (3) Finally, add 20 kg of rubber powder, 5 kg of steel fiber and 5 kg of brucite fiber in turn, and stir for 40 minutes, wherein the particle size of the rubber powder is 0.25 mm, and the apparent density is 1300 kg / m 3 , bulk density is 650kg / m 3 , the steel fibers are milled steel fibers with a length of 30 mm and a diameter of 1.25 mm, and brucite fibers with a diameter of 0.54 μm and a length of 35 mm.

[0047] The raw mat...

preparation example 2

[0049] Preparation Example 2: (1) According to the proportioning in Table 1, 65 kilograms of water, 13 kilograms of polyvinyl alcohol, 8 kilograms of sodium formate, 8 kilograms of potassium thiocyanate, and 8 kilograms of sodium thiosulfate were added to the reactor successively. The temperature of the reactor was controlled at 98°C and stirred for 70 minutes;

[0050] (2) Lower the temperature to 63°C, add 13 kg of ethylene glycol, 7 kg of potassium acetate and 13 kg of sodium nitrate in sequence, and stir for 110 min;

[0051] (3) Finally, add 25 kg of rubber powder, 8 kg of steel fiber and 8 kg of brucite fiber in turn, and stir for 50 minutes, wherein the rubber powder has a particle size of 0.3 mm and an apparent density of 1350 kg / m 3 , bulk density is 660kg / m 3 , the steel fibers are milled steel fibers with a length of 35 mm and a diameter of 1.35 mm, and brucite fibers with a diameter of 0.64 μm and a length of 40 mm.

preparation example 3

[0052] Preparation Example 3: (1) According to the proportioning in Table 1, 80 kilograms of water, 15 kilograms of polyvinyl alcohol, 10 kilograms of sodium formate, 10 kilograms of potassium thiocyanate, and 10 kilograms of sodium thiosulfate were added to the reactor successively, and the The temperature of the reactor was controlled at 100°C and stirred for 80 minutes;

[0053] (2) Lower the temperature to 65°C, add 15 kg of ethylene glycol, 10 kg of potassium acetate and 15 kg of sodium nitrate in sequence, and stir for 120 minutes;

[0054] (3) Finally, add 30 kg of rubber powder, 10 kg of steel fiber and 10 kg of brucite fiber in sequence, and stir for 60 minutes, wherein the particle size of the rubber powder is 0.35 mm, and the apparent density is 1400 kg / m 3 , bulk density is 680kg / m 3 , the steel fibers are milled steel fibers with a length of 40 mm and a diameter of 1.45 mm, and brucite fibers with a diameter of 0.74 μm and a length of 45 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com