(Ti, Al) N reinforced self-shielded flux-cored wire utilizing air N infiltration

A technology of flux-cored welding wire and self-protection, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of high price and increased welding wire manufacturing cost, so as to reduce welding wire cost, save welding wire cost, increase Effect of Strength and Abrasion Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

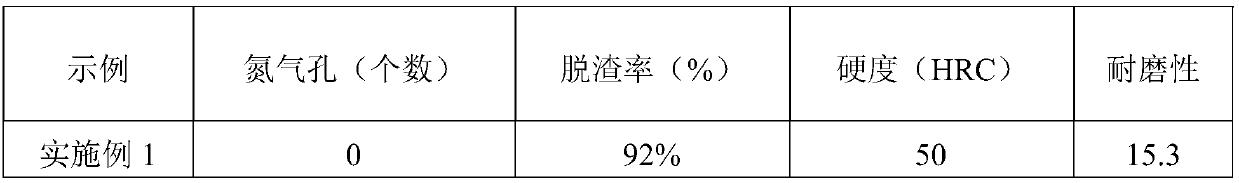

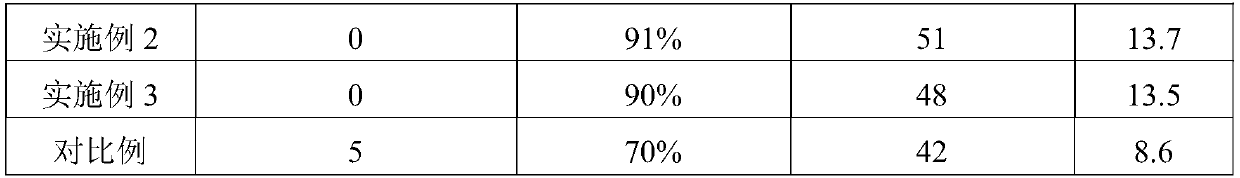

Embodiment 1

[0024] A (Ti,Al)N reinforced self-shielding flux-cored welding wire infiltrated by air, including a low-carbon steel strip and a flux core, the flux core is filled in the steel strip, and the composition of the flux core is prepared according to the following quality: including low-carbon steel Belt and drug core, the drug core is filled in the steel belt, and the components of the drug core are prepared according to the following quality: including low carbon steel belt and drug core, and the drug core is filled in the steel belt. The composition of steel strip H08A is C:0.1%, Mn:0.3~0.55%, Si:0.3%, S:≤0.03%, P:≤0.03%. The drug core composition is prepared according to the following quality: 36g of microcarbon ferrochromium, 25g of mechanical mixture of titanium iron and aluminum powder, 15g of rutile, 6g of marble, 8g of lithium fluoride, 1g of microcarbon ferromanganese, 1g of Potassium fluorosilicate, 1g of sodium alginate, 7g of iron powder. Among them, ferrotitanium: al...

Embodiment 2

[0026] A (Ti,Al)N reinforced self-shielding flux-cored welding wire infiltrated by air, including a low-carbon steel strip and a flux core, the flux core is filled in the steel strip, and the composition of the flux core is prepared according to the following quality: including low-carbon steel Belt and drug core, the drug core is filled in the steel belt, and the components of the drug core are prepared according to the following quality: including low carbon steel belt and drug core, and the drug core is filled in the steel belt. The composition of steel strip H08A is C:0.1%, Mn:0.3~0.55%, Si:0.3%, S:≤0.03%, P:≤0.03%. The drug core composition is prepared according to the following quality: 55g of micro-carbon ferrochrome, 10g of mechanical mixture of titanium and aluminum powder, 10g of rutile, 2g of marble, 3g of lithium fluoride, 3g of micro-carbon ferromanganese, 3g of Potassium fluorosilicate, 1g of sodium alginate, 13g of iron powder. Among them, ferrotitanium: alumin...

Embodiment 3

[0028]A (Ti,Al)N reinforced self-shielding flux-cored welding wire infiltrated by air, including a low-carbon steel strip and a flux core, the flux core is filled in the steel strip, and the composition of the flux core is prepared according to the following quality: including low-carbon steel Belt and drug core, the drug core is filled in the steel belt, and the components of the drug core are prepared according to the following quality: including low carbon steel belt and drug core, and the drug core is filled in the steel belt. The composition of steel strip H08A is C:0.1%, Mn:0.3~0.55%, Si:0.3%, S:≤0.03%, P:≤0.03%. The drug core composition is prepared according to the following quality: 40g of microcarbon ferrochromium, 15g of mechanical mixture of titanium iron and aluminum powder, 20g of rutile, 4g of marble, 5g of lithium fluoride, 2g of microcarbon ferromanganese, 2g of Potassium fluorosilicate, 0.5g of sodium alginate, 11.5g of iron powder. Among them, ferrotitanium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com