Waterproofing and low-voltage aluminum electrolytic capacitor working electrolyte

A technology of aluminum electrolytic capacitors and electrolytes, applied in electrolytic capacitors, capacitors, circuits, etc., can solve problems such as oxide film performance damage, achieve low production costs, simple formulas, and realize the effects of industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

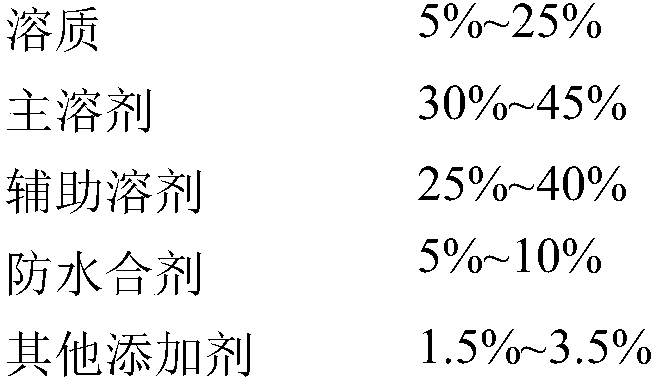

[0033] Embodiment 1 Electrolyte formula and preparation thereof

[0034]

[0035] Preparation process: According to the components in the above table, firstly, heat the main solvent and auxiliary solvent to 60°C and mix them, add the solute adipic acid and ammonium formate, then add the waterproofing agent and other additives and stir for 15 minutes at a constant temperature of 110°C , cooled to room temperature to obtain an electrolyte.

Embodiment 2

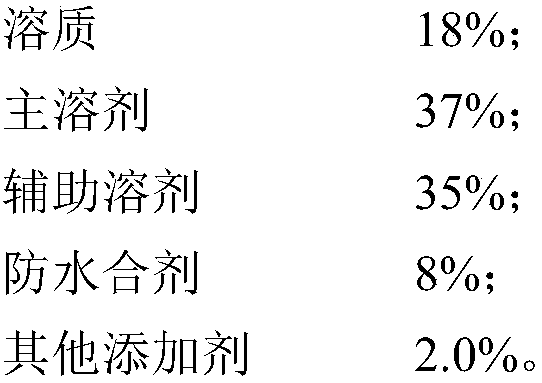

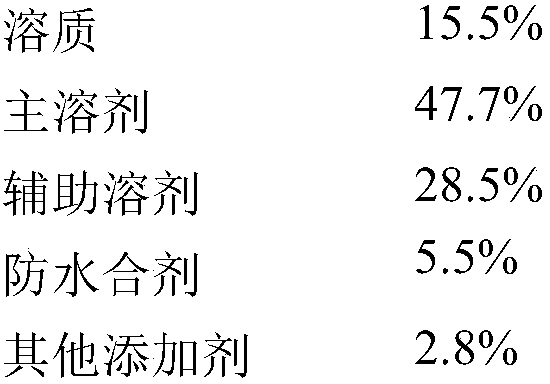

[0036] Embodiment 2 electrolyte formula and preparation thereof

[0037]

[0038] Preparation process: According to the components in the above table, firstly, heat the main solvent and auxiliary solvent to 60°C and mix them, add the solute adipic acid and ammonium formate, then add the waterproofing agent and other additives and stir for 15 minutes at a constant temperature of 110°C , cooled to room temperature to obtain an electrolyte.

Embodiment 3

[0039] Embodiment 3 performance test

[0040] The working electrolyte parameters are shown in Table 1.

[0041] Table 1 Working Electrolyte Test Parameters

[0042] performance parameters

Example 1

Example 2

moisture content

25.0%

20.0%

Conductivity (30℃ms / cm)

35

20

pH

6.68

6.33

Flash voltage

150

280

Low temperature characteristics (-40℃)

Not frozen, not precipitated out

Not frozen, not precipitated out

[0043] The electrical characteristics of the electrolytic capacitor obtained by using the electrolyte of Example 1 of the present invention at a working voltage of 6.3V to 35V are as shown in Table 2; The characteristics are shown in Table 3.

[0044] Table 2 Electrical characteristics under 6.3V~35V working voltage (taking 6.3V 1500μf specification as an example)

[0045]

[0046] Table 3: Electrical characteristics under 50V ~ 100V working voltage (taking 100V 330μf specification a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com